23

Installation manual

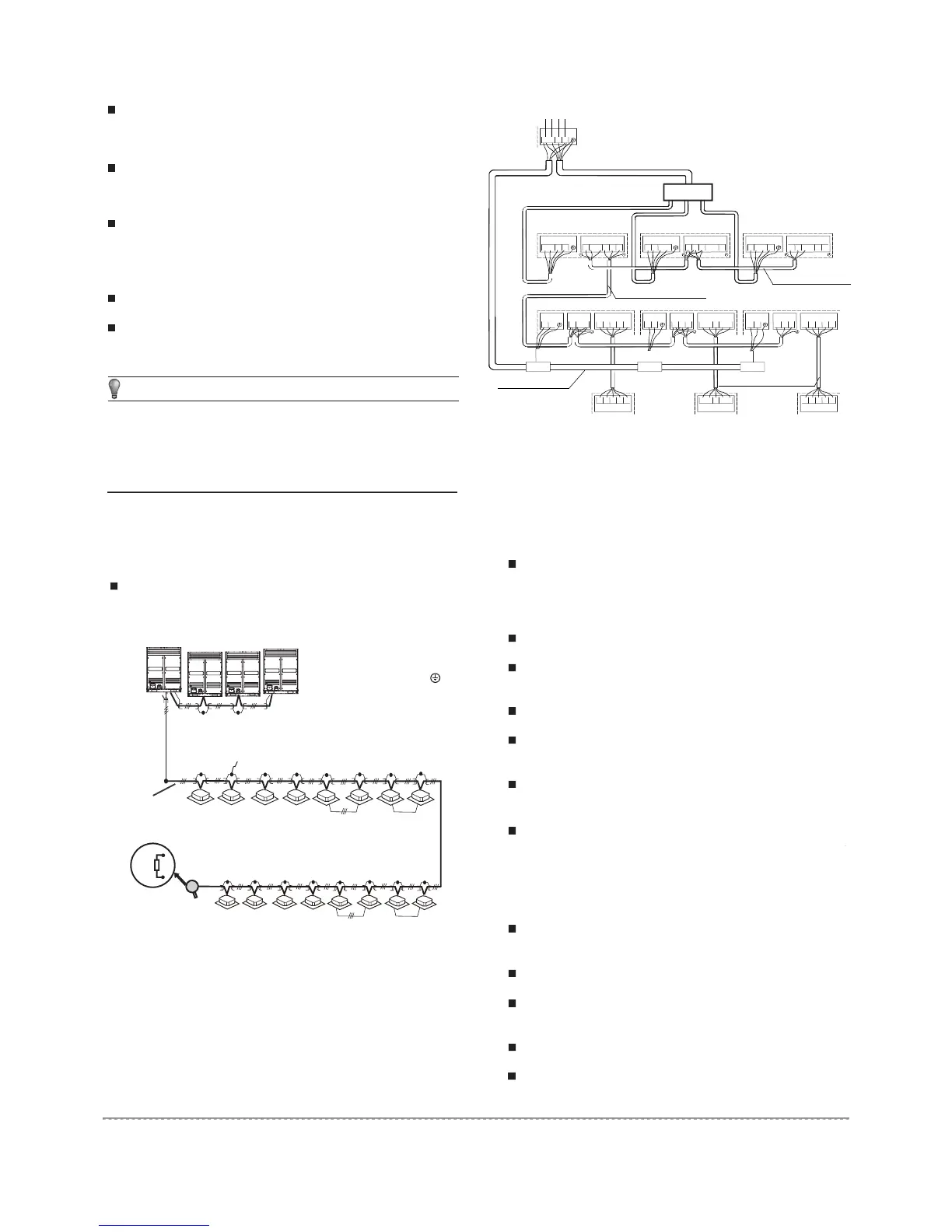

Outdoor unit(master unit)

Outdoor unit(slave unit) Outdoor unit(slave unit)

Signal wire between indoor/outdoor unith

Signal wire between outdoor units

Indoor unit

Indoor unit

Indoor unit

Signal wire between indoor units

Signal wire between indoor unit and wire controller

%&1$ 34((++

/1 (43

%&1$ 34((++ %&1$ 34((++

&'(%$ /1 ( &'(%$ /1 ( &'(%$4343

%&1$

&'(%$ &'(%$ &'(%$

Branch Box

Branch Box

L2

L3

N

L1

Power(380-415V 3N

a

50Hz)

Branch Box Branch Box

Wire controller Wire controller Wire controller

NOTE

The shield net should be grounded at the wiring terminal

of outdoor unit. The inlet and outlet wire net of indoor

communication wire should be connected directly and

could not be grounded, and form open circuit at the shield

net of final indoor unit.

Fig.6-8

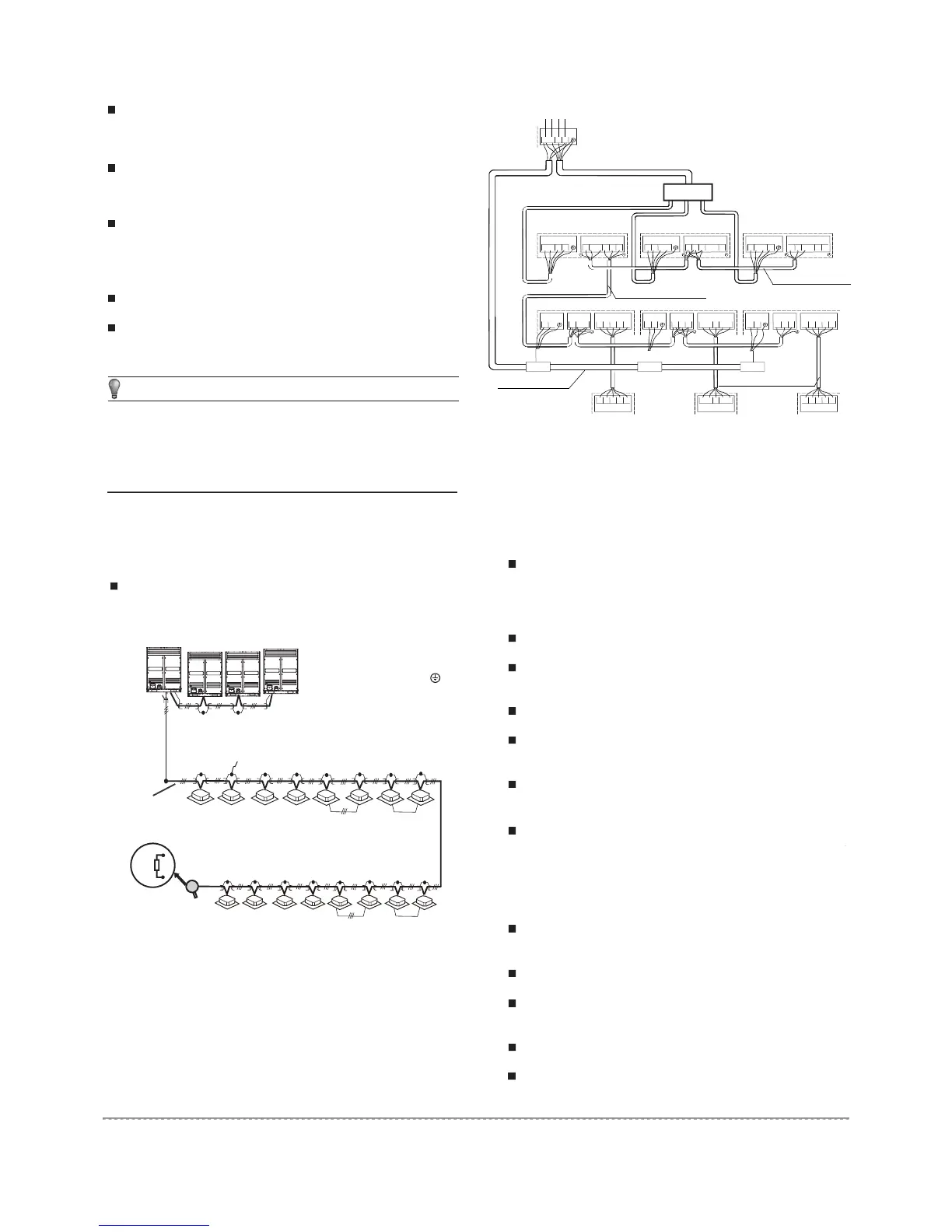

Fig.6-9

The control line should be shielded wire. Using other wiring

shall create signal interference, thus leading to error

operation.

The shielded nets at the two sides of shielded wires are

either grounded to the earth, or connected with each other

and jointed to the sheet metal along to the earth.

Control wire could not be bound together with refrigerant

pipeline and power wire. When power wire and control wire

is distributed in parallel form, keep gap between them above

300mm so as to preventing signal interference.

Control wire could not form closed loop.

Control wire has polarity, so be careful when connecting.

Signal wire of indoor/outdoor unit adopts 3-core shielded wire (

≥0.75mm

2

) which has polarity, please connect it correctly.

Check and confirm that refrigeration pipe line and

communication wire with indoor and outdoor unit have

been connected to the same refrigeration system.

Otherwise, operation troubles shall happen.

Power voltage is within ±10% of rated voltage.

Check and confirm that the power wire and control wire

are correctly connected.

Check whether wire controller is properly connected.

Before powering on, confirm there is no short circuit to

each line.

Check whether all units have passed nitrogen

pressure-keeping test for 24 hours with R410A: 40kg/

CM2

.

Confirm whether the system to debugging has been

carried out vacuum drying and packed with refrigeration as

required.

Calculating the additional refrigerant quantity for each set

of unit according to the actual length of liquid pipe.

Keep required refrigerant ready.

Keep system plan, system piping diagram and control

wiring diagram ready.

Record the setting address code on the system plan.

Turn on power switches outdoor unit in advance, and keep

connected for above 12 hours so that heater heating up

refrigerant oil in compressor.

6.7 Signal wire of indoor/outdoor units

6.8 Example for power wire connection

7.1 Inspection and confirmation before

commissioning

7.2 Preparation before debugging

7. TRIAL RUN

6.6 Control system and Installation

(P Q E)

(H1 H2 E) (H1 H2 E) (H1 H2 E)

(H1 H2 E)

34(

Outdoor unit

(master unit)

Outdoor unit

(slave unit)

Outdoor unit

(slave unit)

Outdoor unit

(slave unit)

Signal wire between outdoor units

To closed end of shield wire

(All shield terminals of shield wires

connect to COMM terminal )

Signal wire of

indoor/outdoor units

(open)

group control

The indoor unit at the terminal of communication system should

parallel connect a impedance between port P and port Q.

3

4

matching

resisitor

Loading...

Loading...