10

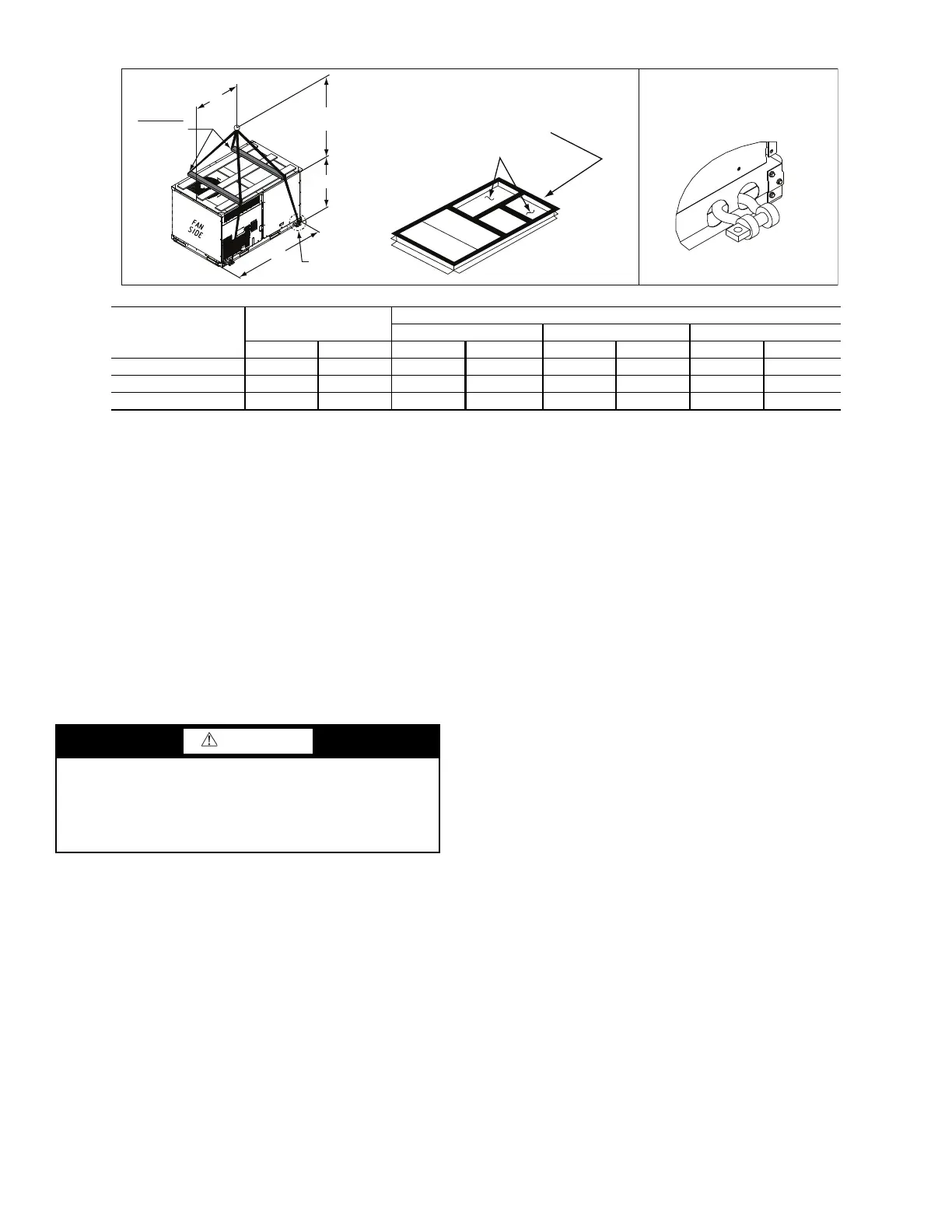

Fig. 6 — Rigging Details

POSITIONING ON CURB

Position unit on roof curb so that the following clearances

are maintained:

1

/

4

in. (6.4 mm) clearance between the roof

curb and the base rail inside the front and rear, 0.0 in. clear-

ance between the roof curb and the base rail inside on the

duct end of the unit. This will result in the distance between

the roof curb and the base rail inside on the condenser end of

the unit being approximately

1

/

4

in. (6.4 mm).

Although unit is weatherproof, guard against water from

higher level runoff and overhangs.

Flue vent discharge must have a minimum horizontal

clearance of 4 ft (1220 mm) from electric and gas meters, gas

regulators, and gas relief equipment. Minimum distance be-

tween unit and other electrically live parts is 48 inches

(1220 mm).

Flue gas can deteriorate building materials. Orient unit

such that flue gas will not affect building materials. Locate

mechanical draft system flue assembly at least 48 in.

(1220 mm) from an adjacent building or combustible

material.

NOTE: Installation of accessory flue discharge deflector kit will

reduce the minimum clearance to combustible material to 18 in.

(460 mm).

After unit is in position, remove rigging skids and ship-

ping materials.

Step 7 — Convert to Horizontal and Connect

Ductwork (When Required)

Unit is shipped in the vertical duct configuration. Unit with-

out factory-installed economizer or return-air smoke detector

option may be field-converted to horizontal ducted configura-

tion. To convert to horizontal configuration, remove screws

from side duct opening covers (see Fig. 7) and remove cov-

ers. Use the screws to install the covers on vertical duct open-

ings with the insulation-side down. The panels must be insert-

ed into the notches on the basepan to properly seal. The

notches are covered by the tape used to secure the insulation

to the basepan and are not easily seen. See Fig. 8 for position

of the notches in the basepan. Seals around duct openings

must be tight. Secure with screws as shown in Fig. 9. Cover

seams with foil duct tape.

Field-supplied flanges should be attached to horizontal duct

openings and all ductwork should be secured to the flanges.

Insulate and weatherproof all external ductwork, joints, and

roof or building openings with counter flashing and mastic in

accordance with applicable codes.

Do not cover or obscure visibility to the unit’s informative

data plate when insulating horizontal ductwork.

DETAIL "A"

PLACE ALL SEAL STRIP IN PLACE

BEFORE PLACING UNIT ON ROOF CURB.

DUCT END

SEE DETAIL "A"

"A"

(914-1371)

36"- 54"

"C"

"B"

SPREADER

BARS

REQUIRED

UNIT

MAX WEIGHT

DIMENSIONS

ABC

lb kg in. mm in. mm in. mm

48KC-A04 795 361 74.5 1890 39 990 33.5 850

48KC-A05 890 405 74.5 1890 39 990 33.5 850

48KC-A06 1020 464 74.5 1890 39 990 41.5 1055

NOTES:

1. SPREADER BARS ARE REQUIRED. Top damage will occur if spreader bars are not used.

2. Dimensions in () are in millimeters.

3. Hook rigging shackles through holes in base rail, as shown in Detail A. Holes in base rails are centered around the unit center of gravity. Use

wooden top to prevent rigging straps from damaging unit.

CAUTION

Failure to follow this caution may result in equipment dam-

age.

All panels must be in place when rigging. Unit is not

designed for handling by fork truck when panels or packag-

ing are removed.

Loading...

Loading...