24

Installation manual

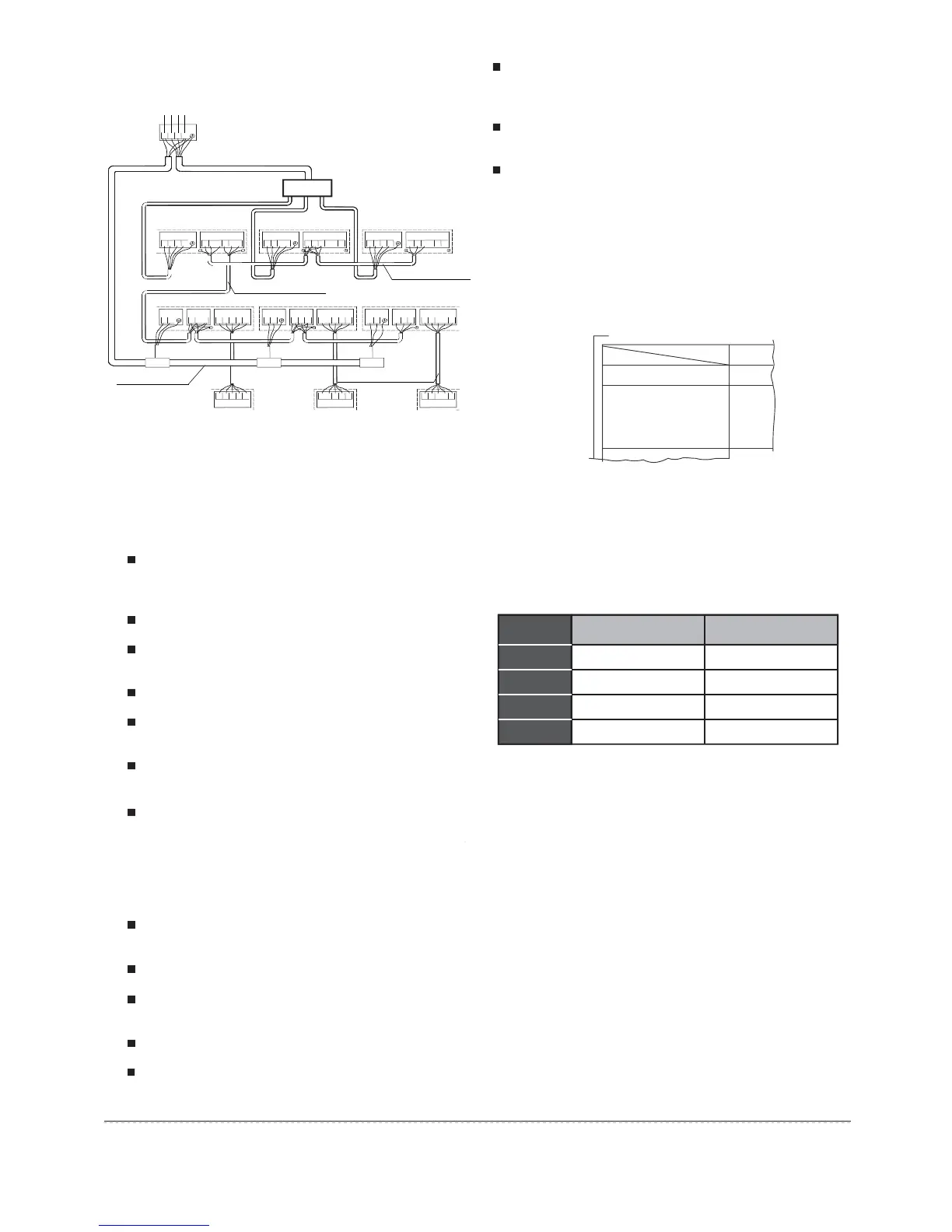

Fig.7-1

Fully turn on the air pipe stop valve, liquid pipe stop valve, oil

balance valve, and air balance valve. If the above valves are

not turned on fully, the unit will be damaged.

Check whether the power phase sequence of outdoor unit is

correct.

All dial switches for indoor and outdoor units are set according

to the Technical Requirements of the Product.

7.3 Fill the name of connected system

To clearly identify the connected systems between two or

more indoor units and the outdoor unit, select names for

every system, and record them on the nameplate on the

outdoor electric control box cover.

Model(indoor unit)

Room Name e.g., indoor

unit (A) of the first system

on second floor is recorded

as:-2F-1A

Outdoor unit(master unit)

Outdoor unit(slave unit) Outdoor unit(slave unit)

Signal wire between indoor/outdoor units

Signal wire between outdoor units

Indoor unit

Indoor unit

Indoor unit

Signal wire between indoor units

Signal wire between indoor unit and wire controller

B C N A P Q E E H2 H1

L N E Q P

B C N A P Q E E H2 H1 B C N A P Q E E H2 H1

C D E B A L N E C D E B A L N E C D E B A Q P Q P

B C N A

C D E B A C D E B A C D E B A

Branch Box

Branch Box

L2

L3

N

L1

Power(380-415V 3N

~

50Hz/60Hz)

Branch Box Branch Box

Wire controller Wire controller Wire controller

Fig.6-11

Check that the refrigeration pipe line and communication

wire between the indoor and outdoor units are connected

to the same refrigeration system or faults will occur.

Power voltage is within ±10% of the rated voltage.

Check that the power wire and control wire are correctly

connected.

Check that the wire controller is properly connected.

Before powering on, confirm there is no short circuit on

each line.

Check whether all units have passed a nitrogen pressure

test for 24 hours with R410A: 40 kg/cm

2

.

Confirm whether system debugging has been carried out

for vacuum drying and packed with refrigeration as

required.

Calculating the additional refrigerant quantity for each set

of units according to the actual length of the liquid pipe.

Keep the required refrigerant ready.

Keep the system plan, system piping diagram, and control

wiring diagram handy.

Record the setting address code on the system plan.

Turn on the power switches for outdoor units in advance,

and keep them connected for at least 12 hours, so that the

heater heats up the refrigerant oil in compressor.

6.8 Example for power wire connection

7.1 Inspection and confirmation before

commissioning

7.2 Preparation before debugging

7. TRIAL RUN

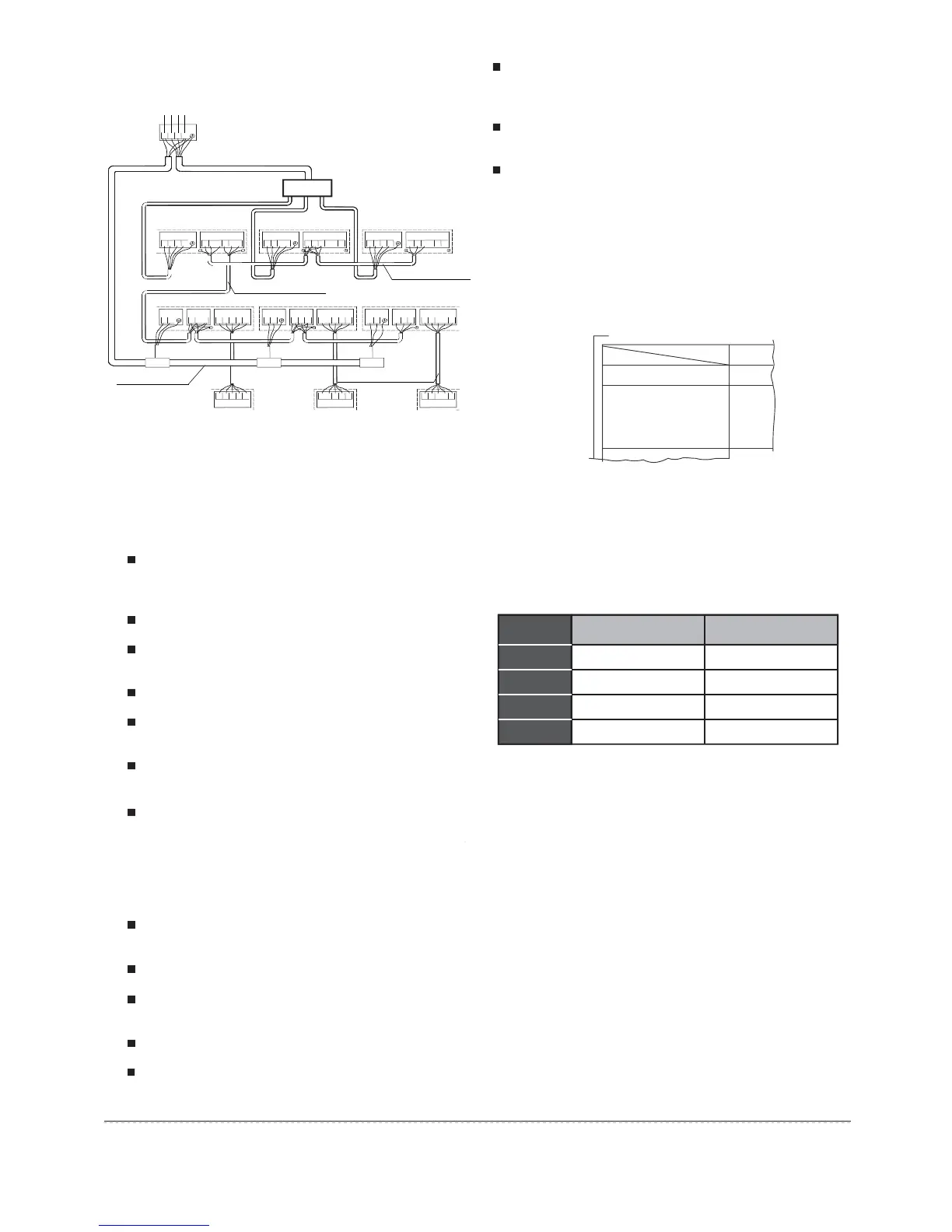

Table.7-1

Factory charge / kg tonnes CO2 equivalent

Model

8,10HP

12HP

9.00

11.00

22.97

14,16,18HP

13.00

27.14

20,22HP 16.00

33.41

18.79

This product has the fluorinated gas which is listed in kyoto

protocol it is forbidden to release to air.

Refrigerant type: R410A,volume of GWP: 2088,

GWP=Global Warming Potential

7.4 Important information for the used

refrigerant

Attention:

Frequency of Refrigerant Leak Checks.

1) For equipment that contains fluorinated greenhouse gases in

quantities of 5 tonnes of CO

2 equivalent or more,but of less

than 50 tonnes of CO

2 equipment,at least every 12 monthes,or

where a leakage detection system is installed, at least every 24

monthes.

2) For equipment that contains fluorinated greenhouse gases in

quantities of 50 tonnes of CO2 equivalent or more,but of less

than 500 tonnes of CO2 equipment,at least every six monthes,

or where a leakage detection system is installed, at least every

12 monthes.

3) For equipment that contains fluorinated greenhouse gases in

quantities of 500 tonnes of CO2 equivalent or more,at least

every three monthes ,or where a leakage detection system is

installed, at least every six monthes.

4) Non-hermetically sealed equipment charged with fluorinated

greenhouse gases shall only be sold to the end user where

evidence is provide that the installation is to be carried out by

an undertaking certified person.

5) Only certificated person is allowed to do installation, operation

and maintenance.

Loading...

Loading...