SECTION 2 - CONTROLS, INSTRUMENTS AND OPERATION

2ï20

File down sharp edges from the tube, remove any

swarf and thoroughly grease the telescoping tube.

IMPORTANT: Further modifications to the PTO shafts and

guards are not allowed.

30

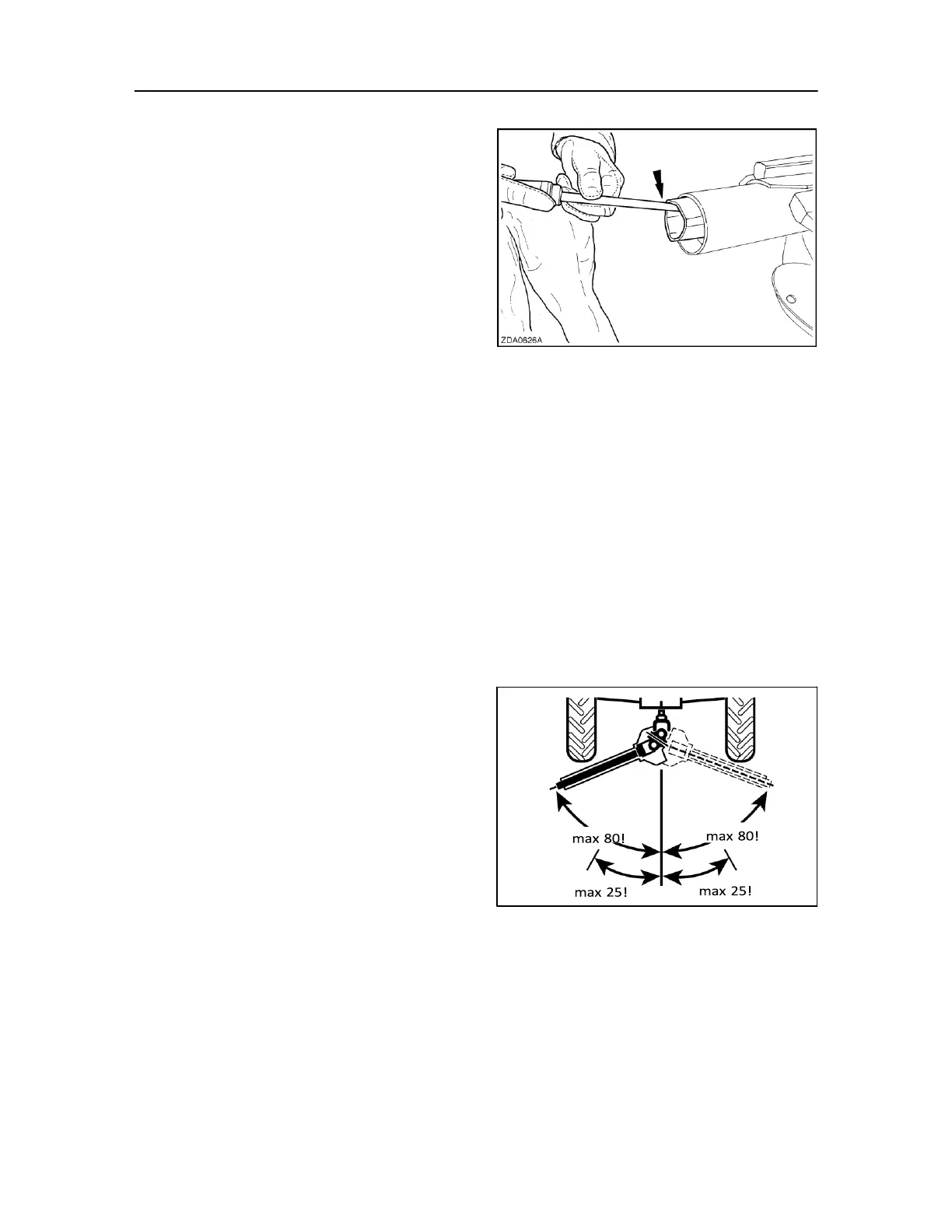

Install the PTO shaft to the tractor as follows: • The front yoke of the driveline is equipped with a push-pull collar.

Connect the yoke to the tractor PTO shaft by pushing the locking collar to release the retaining device.

• Slide the yoke forward until the locking collar

automatically resets in its clamped position

on the groove of the tractor PTO shaft.

ATTENTION: To ensure the driveline is well clamped to the

tractor PTO shaft, move the front U-joint forward and

rearward. The front yoke should remain locked on the

tractor shaft.

To prevent any vibration on the driveline the front yoke

must be free of backlash on the tractor shaft. Replace any

worn parts as necessary.

Check for possible interference with baler tongue

components, hydraulic hoses and wiring looms.

NOTE: It is preferable to have a positive limitation on the

turning angle (i.e. tires contacting the baler tongue),

rather than having the possibility to exceed the PTO shaft

design capabilities.

IMPORTANT: Avoid sharp turning. If you can not avoid

this, lift the pick-up to stop crop intake and reduce or stop

the PTO speed.

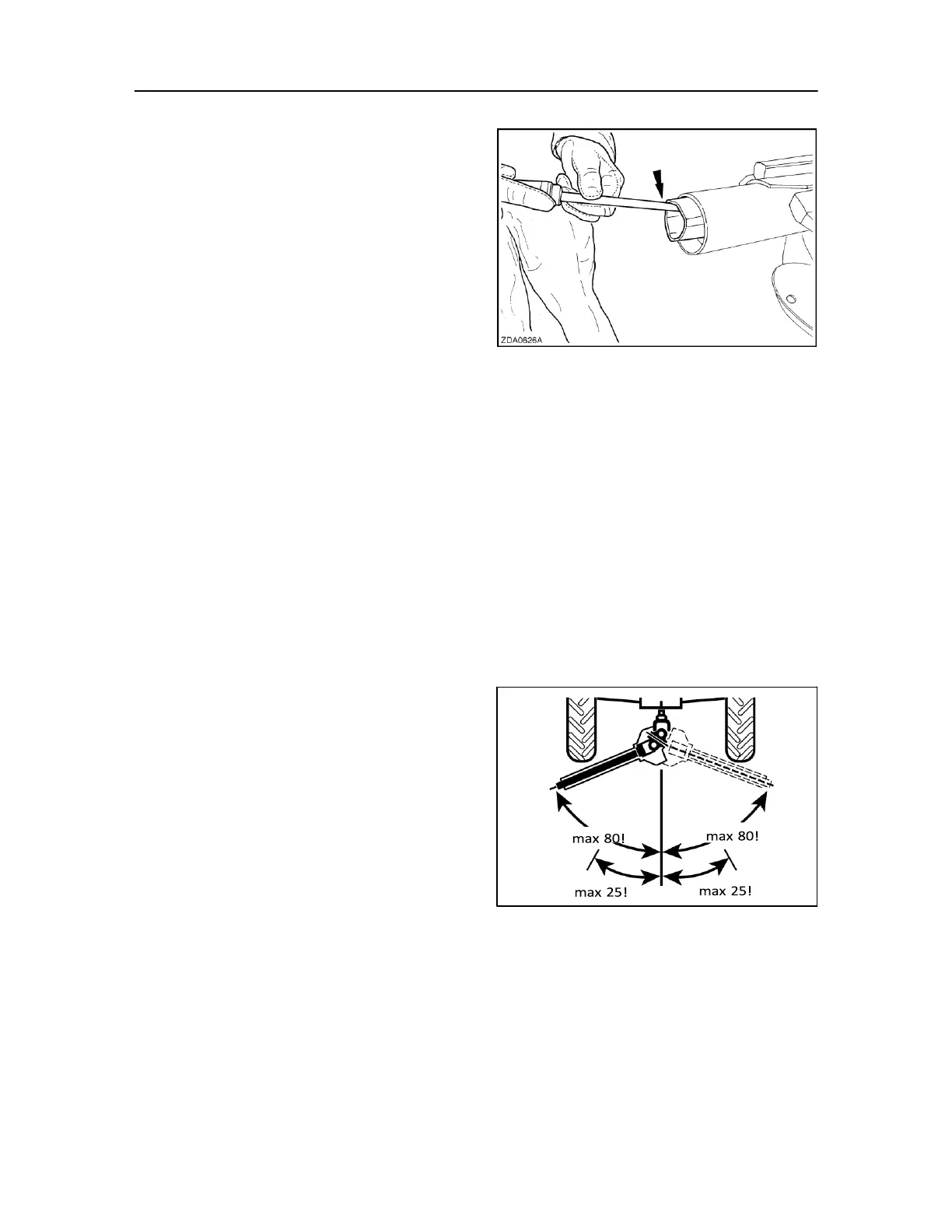

Restrict the PTO angle to:

• Maximum 80° when disengaged or running idle.

• Maximum 25° for continuous operation under

heavy load.

Loading...

Loading...