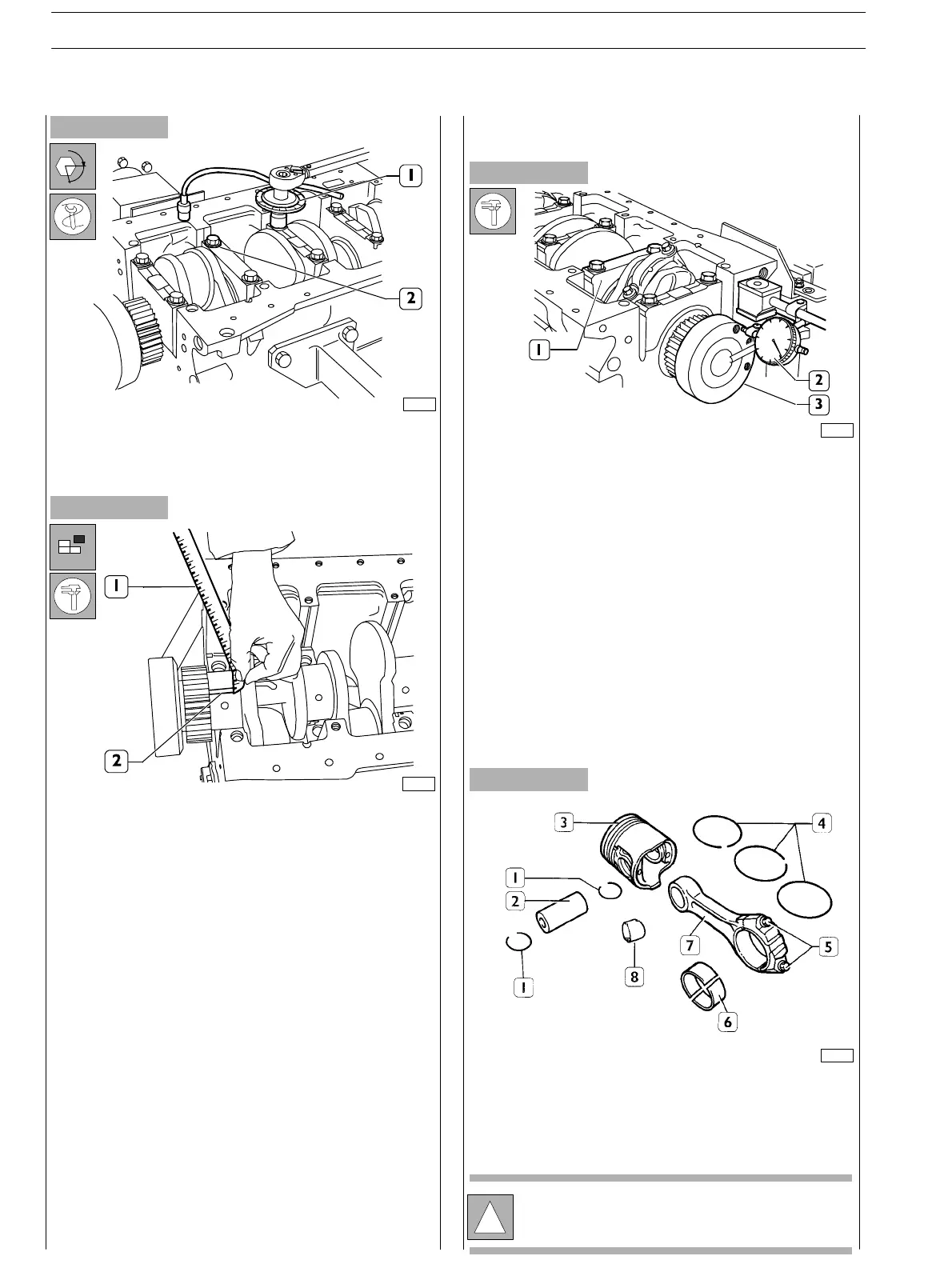

This check is performed by setting a magnetic−base dial gauge

(2) on the output shaft (3) as shown in the figure, standard

value is 0.068 to 0.41.

If higher value is found, replace main th rust half bearings of

the s econd last rear support (1) and repeat the clearance

check between ou tput shaft pins and main half bearin gs.

70188

70189

70190

70191

Figure 36

Figure 37

Figure 38

Figure 39

-

3rd stage, using acceptable tools (I) set as shown in the

figure, tighten the screws (2) with 90°±5° angle.

- Remove caps from supports.

The backlash between the main bearings and the pins is

found by comparing the width of the calibrated wire (2) at

the narrowest point w ith the scale on the envelope (1)

containing the calibrated wire.

The number s on the scale indicate the backlash in mm.

Replace the half bearings and repeat the check if a different

backlash value is found. Once the specified backlash is

obtained, lubricate the main bearings and fit the supports by

tightening the fastening screws as previously described.

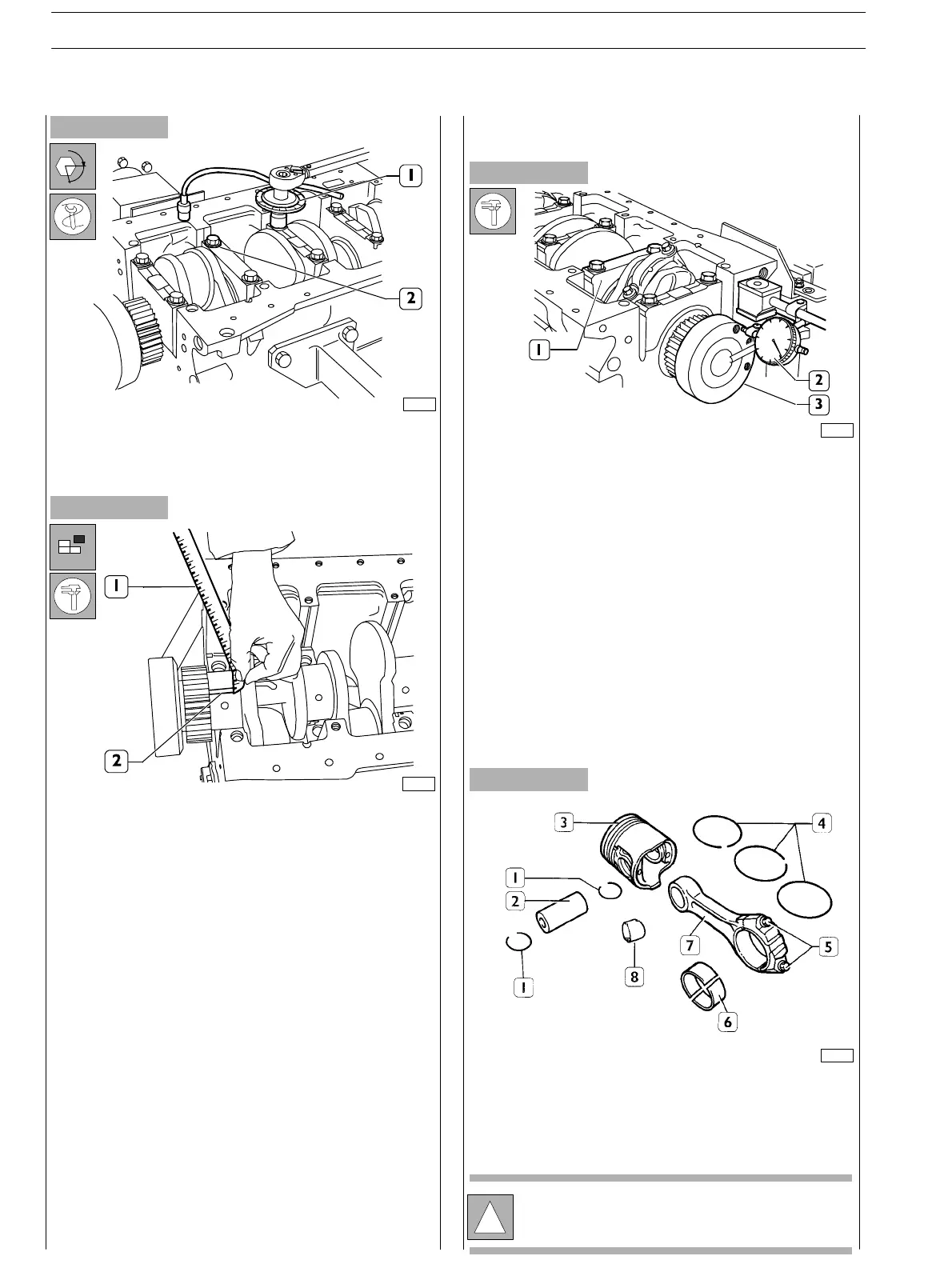

CONNECTING ROD — PISTON ASSEMBLY

COMPONENTS

1. Stop rings − 2. Pin − 3. Piston − 4. Split rings − 5. Screws

− 6. Half bearings − 7. Connecting rod − 8. Bush.

α

Checking output shaft shoulder clearance

!

Pistons are supplied spare with 0.5 mm oversize.

CONNECTING ROD — PISTON

ASSEMBLY

SECTION 4 − OVERHAUL AND TECHNICAL SPECIFICATIONS

22

E NG I NE S

ED. FEBUARY 2003

Loading...

Loading...