61696

61694

61695

70198

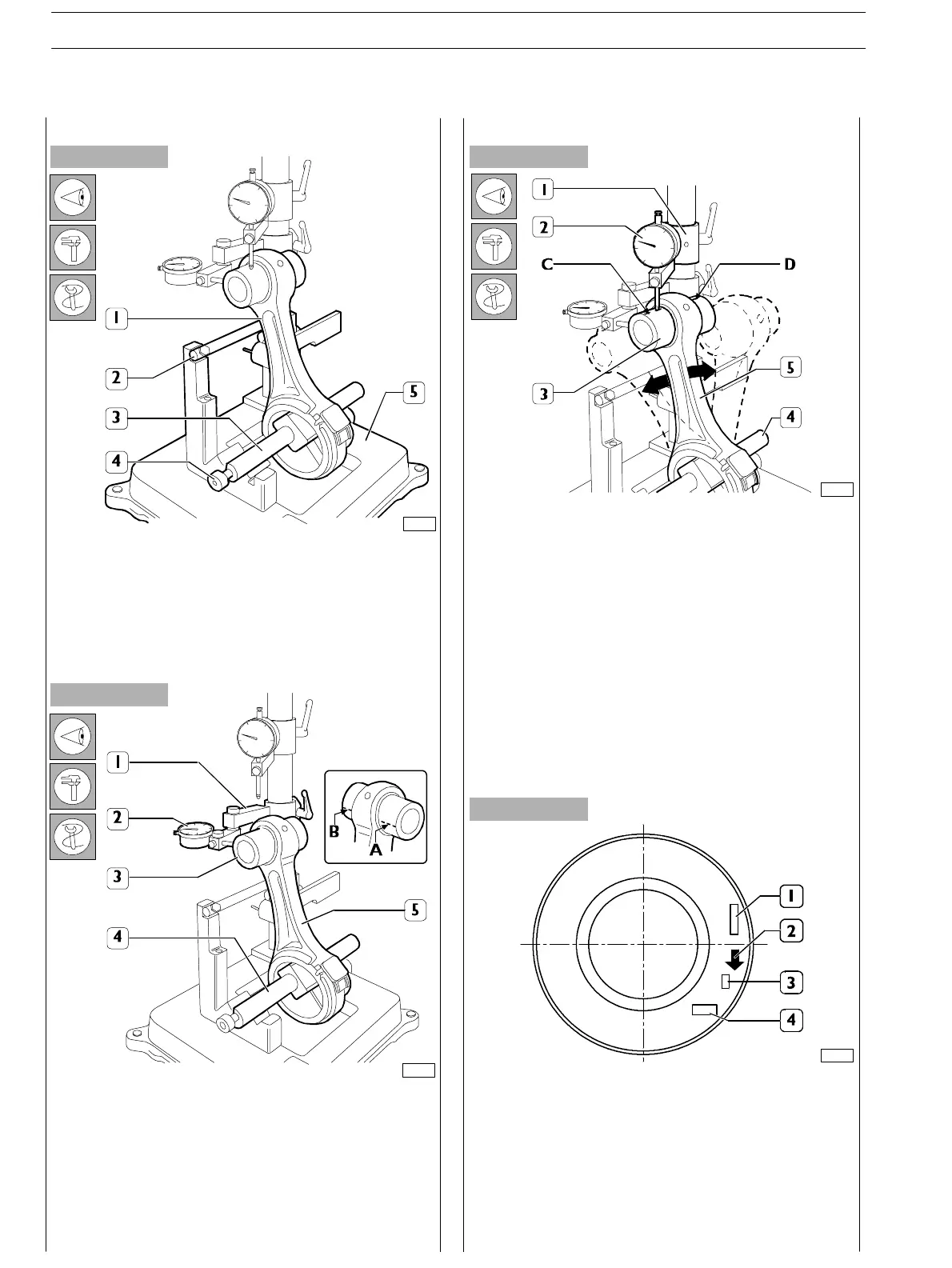

Figure 53

Figure 54

Figure 55

Figure 56

Check that the axes of the connecting rods (1) are parallel

u s in g acceptable tools (5) as fo llow s :

-

fit the connecting rod (I) on acceptable tool (5) spindle

and lock it with screw (4);

- set t he spindle (3) on V−blocks by resting the connecting

rod (1) on th e sto p bar (2).

Check c onnecting rod (5) torsion by comparing t wo points

(A and B) of pin (3) on the horizontal plane of the connecting

rod axis.

Position the dial gauge (2) s upport (1) to obtain a preload o f

approx. 0.5 mm on the pin (3) in point A and then set the

dial gauge (2) to zero. Move the spindle (4) with th e

connecting rod (5) and compare any deviation on the

opposite side (B) of the pin (3): the difference between A and

B shall not exceed 0.08 mm.

Checkconnectingrod(5)bendingbycomparingtwopoints

C and D of the pin (3) on the vertical plane of the connecting

rod axis.

Position the vertical support (1) of the dial gauge (2) to rest

the latter on pin (3), point C .

Move the c onnecting rod forwards an d backwards t o find pin

top position, then in this condition reset the dial gau ge (2).

Move the spindle with the c onnecting rod (5) and repeat the

check of the top point on the opposite side D of the pin (3).

The difference between point C and point D shall not exceed

0.08 mm.

Fitting connecting rod−piston assembly

Connecting rod−piston coupling

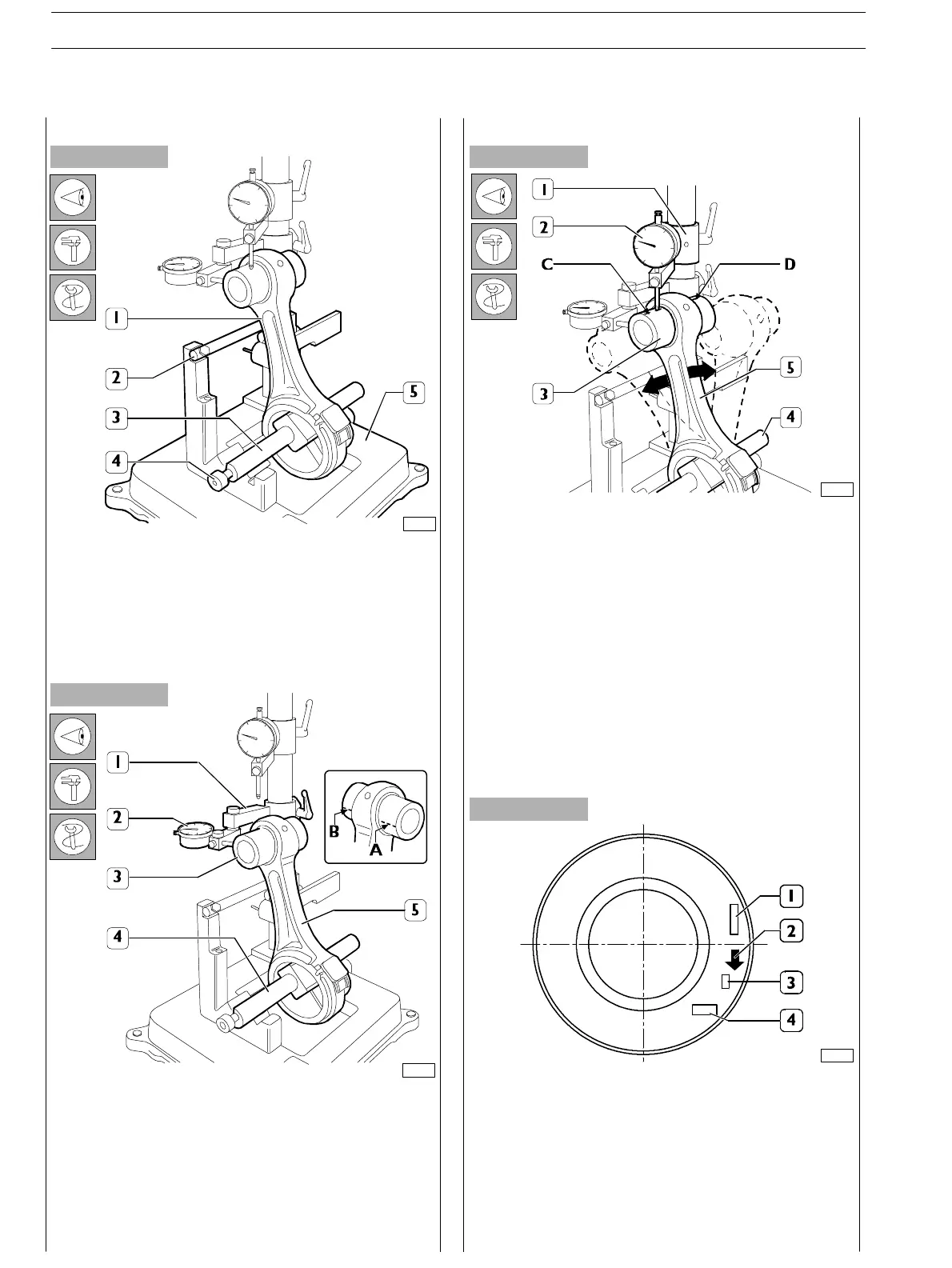

The piston crown is marked as follows:

1. Part number and design modification number;

2. Arrow showing piston assembling direction into cylinder

barrel, this ar row shall face the front key of the engine

block;

3. Mar king showing 1

st

slot insert testing;

4. Manufacturing date.

Checking connecting rods Checking bending

Checking torsion

SECTION 4 − OVERHAUL AND TECHNICAL SPECIFICATIONS

26

E NG I NE S

ED. FEBUARY 2003

Loading...

Loading...