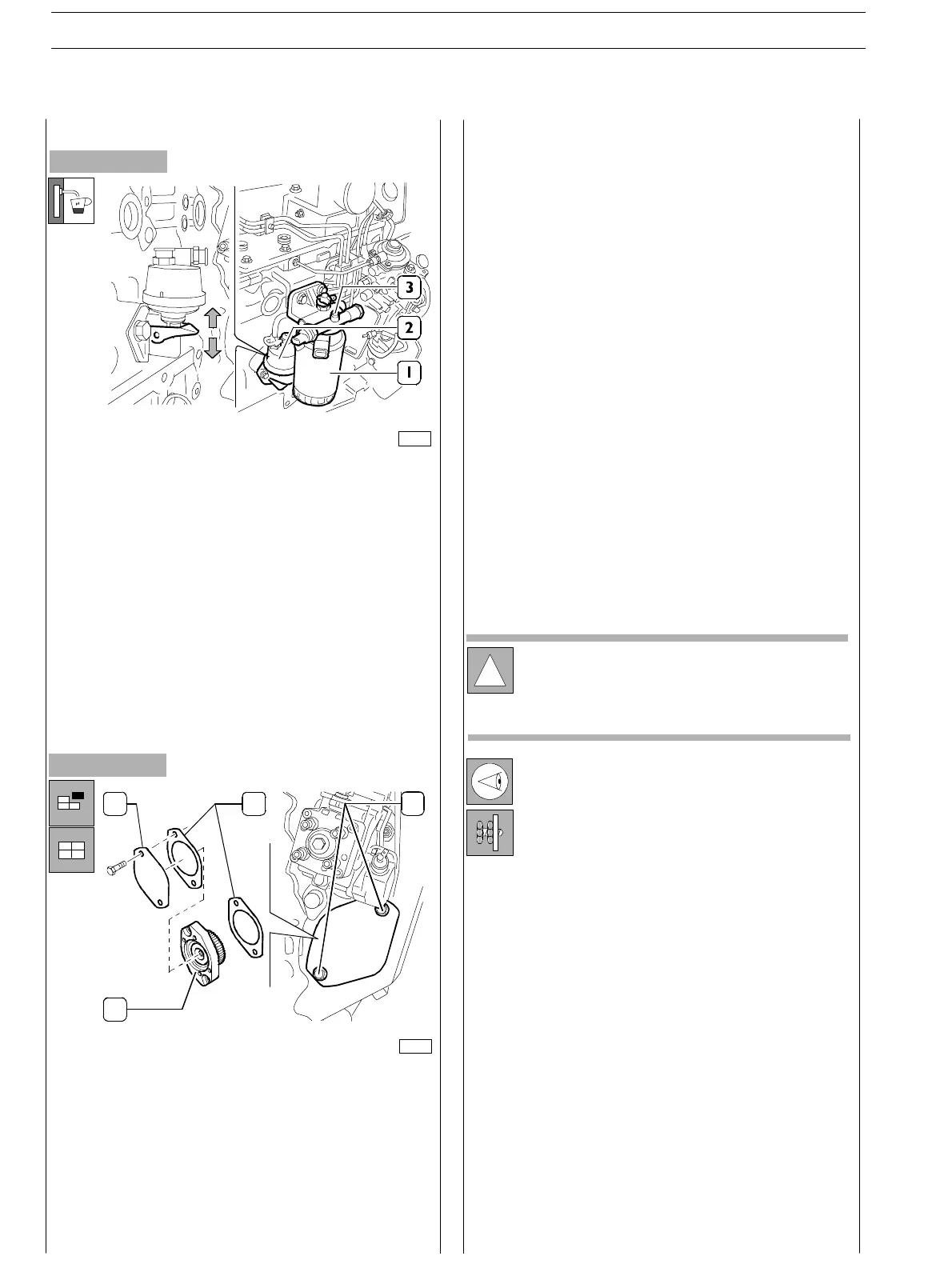

Figure 103

In case any operation has been executed on the components

of the feed circuit, it is necessary to execute bleed ing of air

within the system.

- Loosen the bleed er vent screw (3) on the fuel filter (1)

and keep working on the bleed lever of the priming

pump (2).

- Continue executing this operation until when fuel drains

from the bleeder vent screw.

- Tighten the bleeder vent screw (3)

- Vary out the assembly fitting the power take−off in its

housing, providing new gasket and c hecking t he sprocket

gear meshing.

- Assemble cover and gasket and tighten the screws to the

prescribed couple.

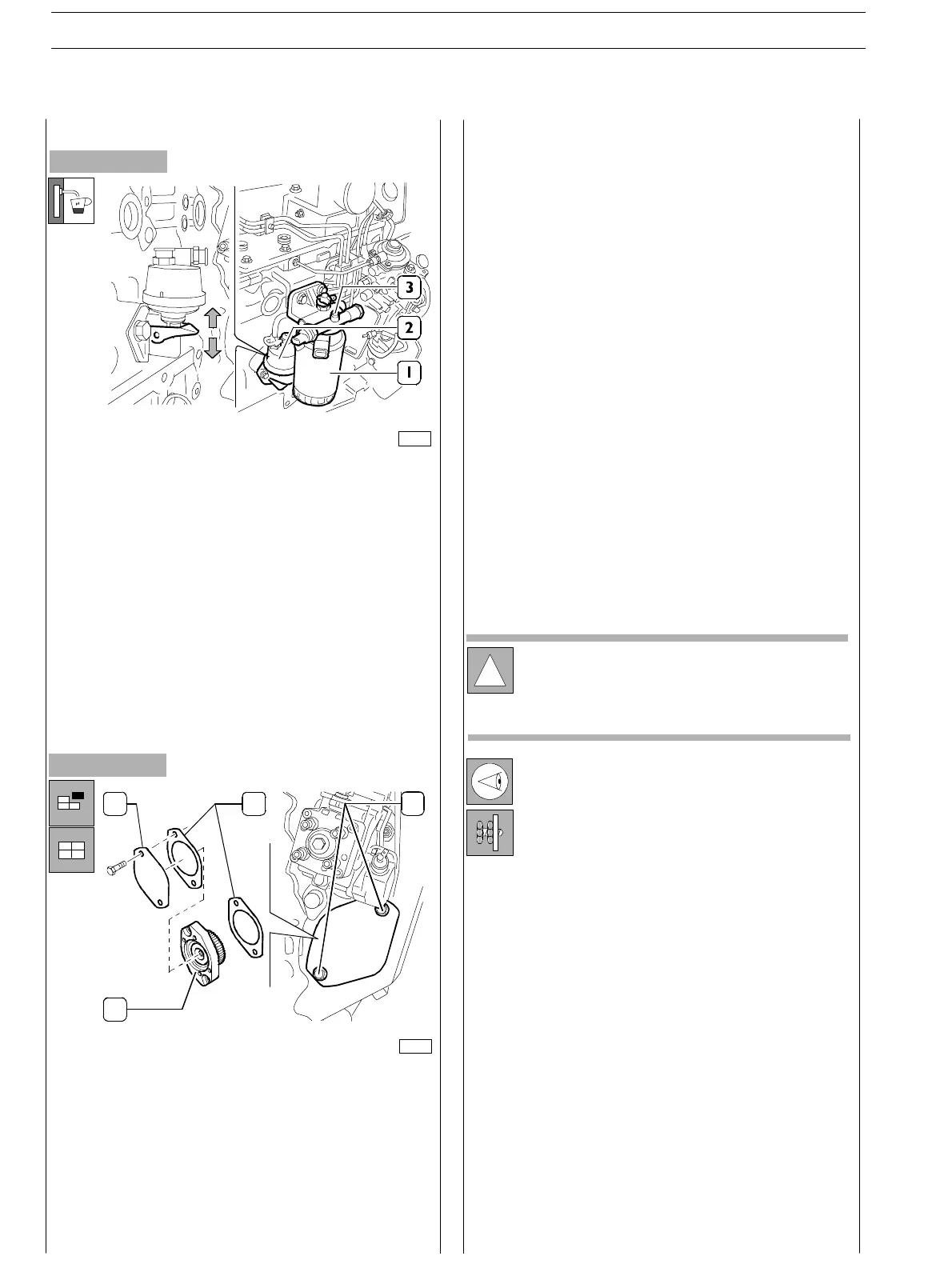

Figure 104

!

The following tests shall be made after engine

assembly to th e vehicle.

Preventively check that the liquid levels have been

correctly restored.

Feed system bleed procedure

Where designed, there is a power take−off able to tr ansmit

motion to different auxiliary parts.

Disassembly of such mechanism shall be execu t ed as

following:

- Loosen the two screws (3) and after having removed the

cover (1) with a spec ially provided extractor, with dr aw

the power take−off (2).

- The two gaskets (4) shall be replaced in phase of

reassemble.

Power take−off disassembly and assembly

procedure

75720

1

2

34

Checks and controls

- There is no water bleeding from the manifolds

conn ec t ing engine cooling circuit pipelines and cabin

intern al heating, eventually providing to further tighten

the locking rings.

- Carefully check the fuel connection pipes to the

respective unions.

- There is no oil leakage from the lubr i cation circuit of the

various pipelines co nnecting cover an d.

- Cylin der head, oil pan and bearin g, oil filter and heat

exchanger as well as relating housings.

- There is n o fuel leakage from fu el pipelines.

- There is no blow−by from pneumatic pipes (if provided).

- Verify cor rect working of the lighting leds of the

dashboardcontainingthetoolsaswellasofthe

equipment that was disconnected during engine

disconnection.

- Check and blow by with care the engine cooling system,

carrying out frequent drainage.

Start the engine, let it run at revolution regimen

slightly higher than idling and wait that the coolin g

liquid temperature reaches the value enabling

thermostat opening, then check that:

76211

SECTION 3 − DUTY − INDUSTRIAL APPLICATION

38

E NG I NE S

ED. FEBUARY 2003

zs

Loading...

Loading...