75753

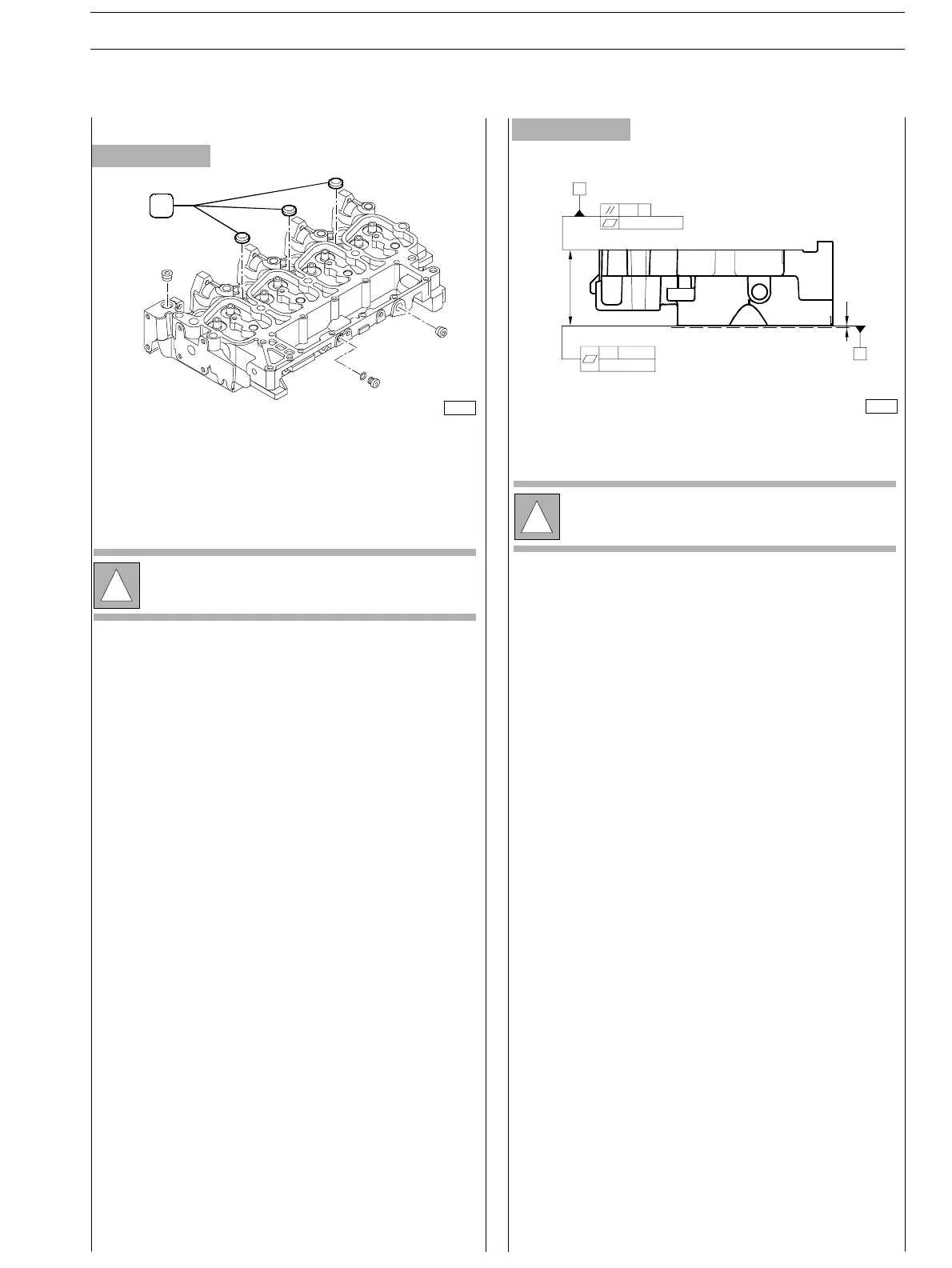

Figure 72

This check shall be performed using the proper tools.

Use a pump to fill with water heated to approx. 90°Cand2

to 3 bar pressure.

Replace t he cup plugs (1) if leaks are foun d, use t he proper

beater for their removal/refitting.

Replace t he cylinder head if leaks are found.

Checking cylinder head wet seal

!

Before refitting, smear the plug surfaces with

water−repellent sealant.

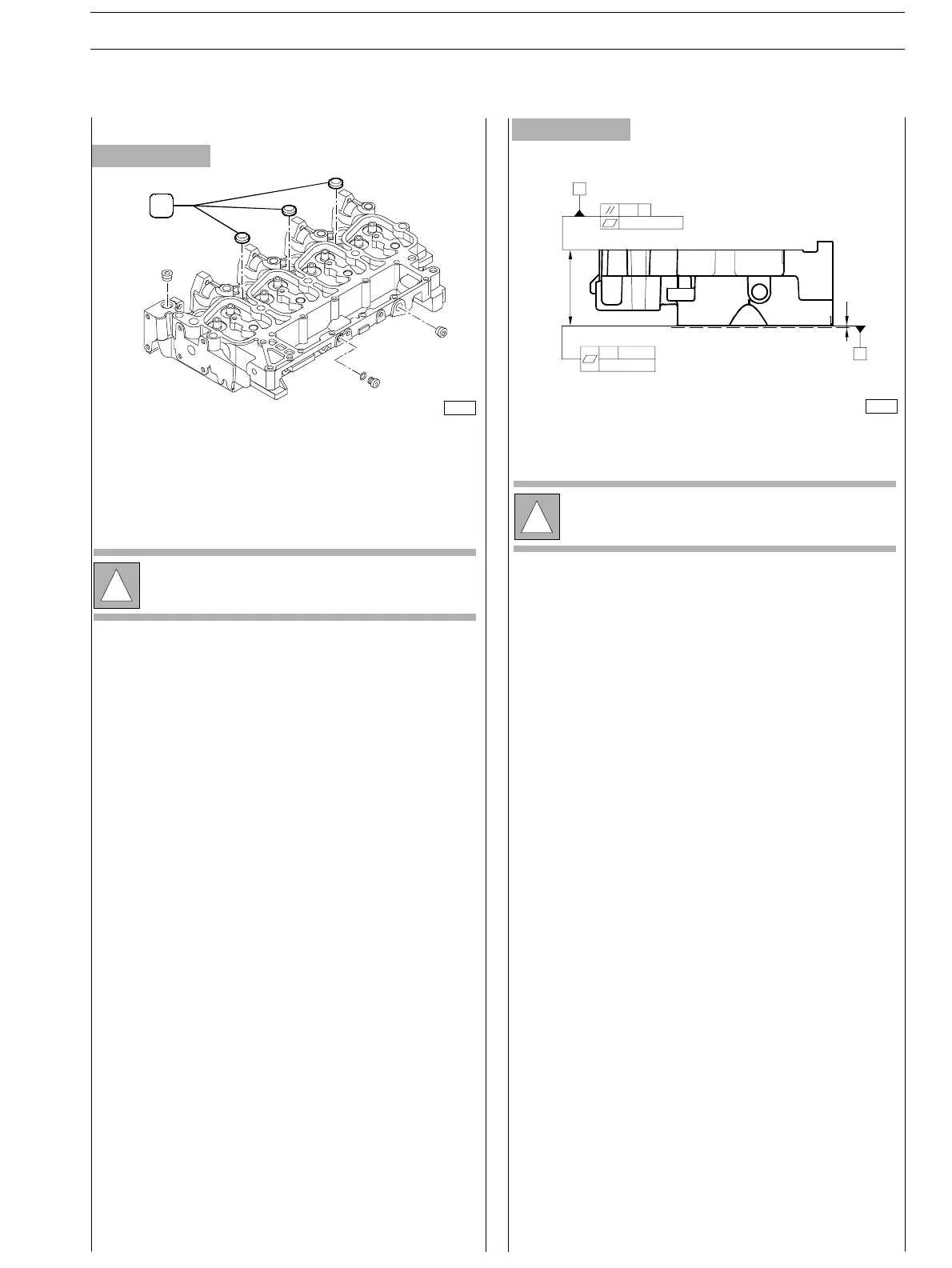

Checking cylinder head supporting surface

Distortion found along the whole cylinder head shall not

exceed 0.20 mm.

If higher values are found gr ind the cylinder head according

to values and indications shown in the following figure.

75756

Figure 73

The rated thickness A for the cylinder head is 95 ± 0.25 mm,

max. metal removal shall not exceed thickness B by 1 mm.

!

After grinding, check valve sinking. Regrind the valve

seats, if required, to obtain the specified value.

1

0,4

C

D

0,025 / ¯ 25,4

0,4

TOT AL

C

0,01 / ¯ 50

AB

SECTION 4 − OVERHAUL AND TECHNICAL SPECIFICATIONS E NG I NE S

31

ED. FEBUARY 2003

Loading...

Loading...