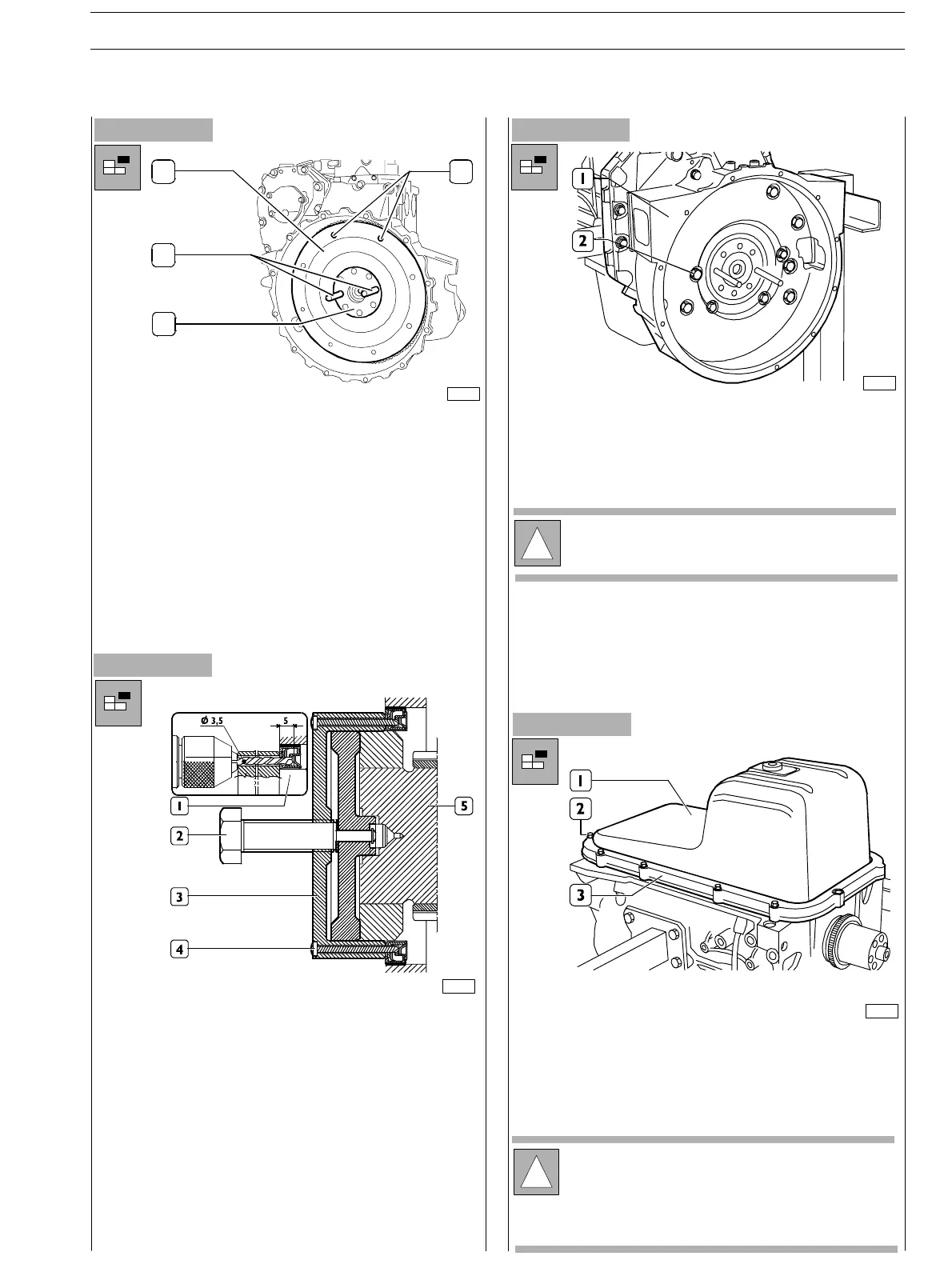

Figure 31

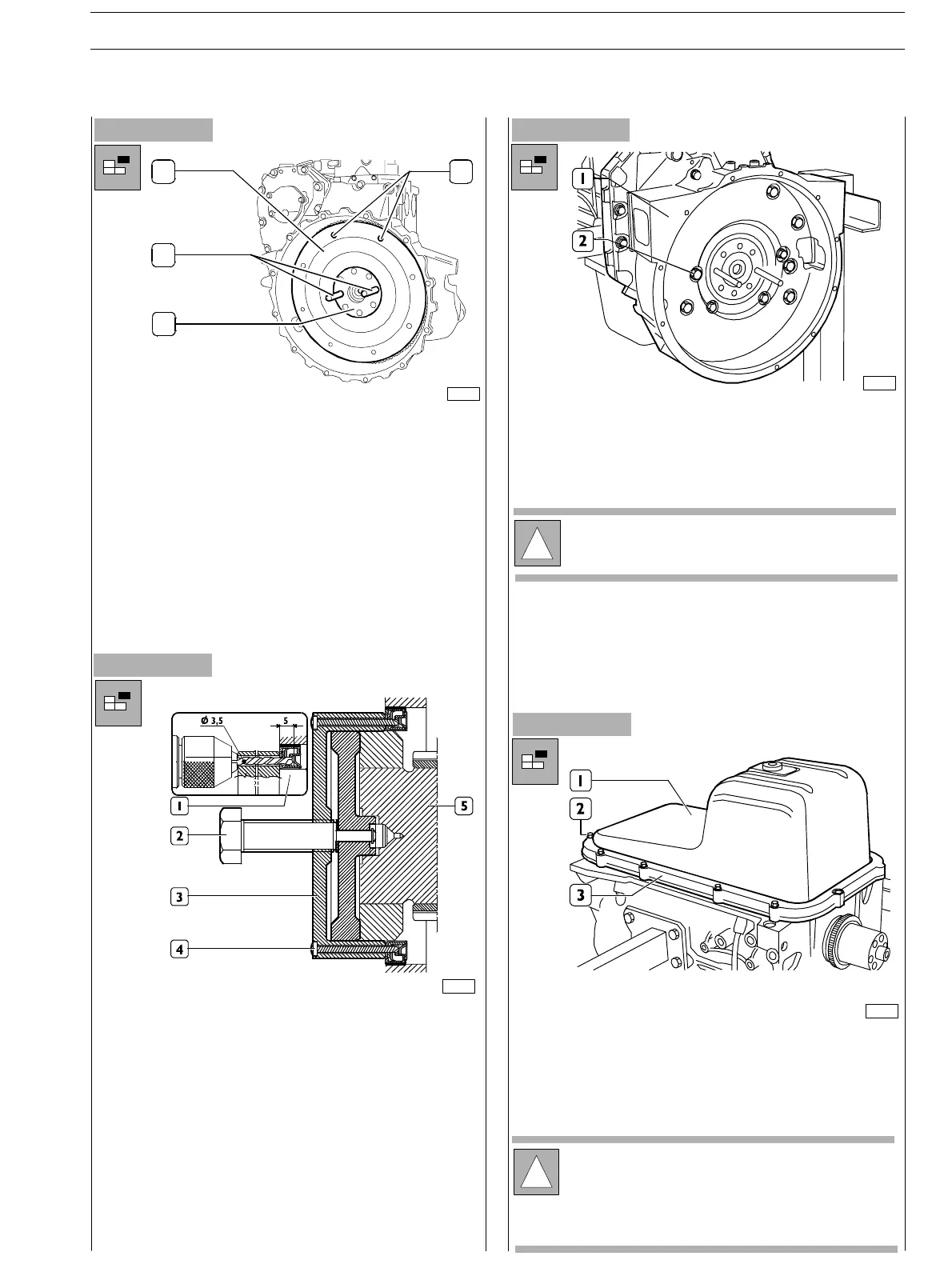

Figure 32

- Screw up two medium length screws in the ports (4) to

slingtheflywheelwithahoist.

Throughout two guide pins (2) previously screwed up

into the engine drive shaft ports (3) control the engine

flywh eel withdrawal by means of a hoist.

- Remove the flywheel cover box fixing r ing using the tool

380000663 (3) t o o per at e o n t h e bac k t an g (5) o f t h e

engine drive shaft. Throughout the tool guide ports, drill

the internal holding ring using Ø 3,5 mm drill for a 5mm

depth.

- Fi x t h e t o o l 380000663 (3) t o t h e r i n g (1) t igh t en in g t h e

6 screws specially provided (4).

- Proceed with drawing the ring (1) tightening the screw

(2).

-

Use acceptable tools (3) (4) and withdraw the external

holding ring of the flywheel cover box.

- Loosen the screws (2) and remove the flywheel cover

box (1).

!

Take note of the screw (1) assembly position, since

the screws have different length.

Figure 33

Figure 34

- Turntheengineupside−down.

- Loosen th e screws (2), disassemble the plate (3) and

remove the oil pan (1).

1

2

3

4

75690

00903t

70153

70154

!

The shape and dimensions of the pan and of the rose

pipe may vary according to the engine application.

The relating illustrations provide general guidelines

of the operation to be performed. The procedures

described are applicable anyway.

SECTION 3 − DUTY − INDUSTRIAL APPLICATION E NG I NE S

17

ED. FEBUARY 2003

zs

Loading...

Loading...