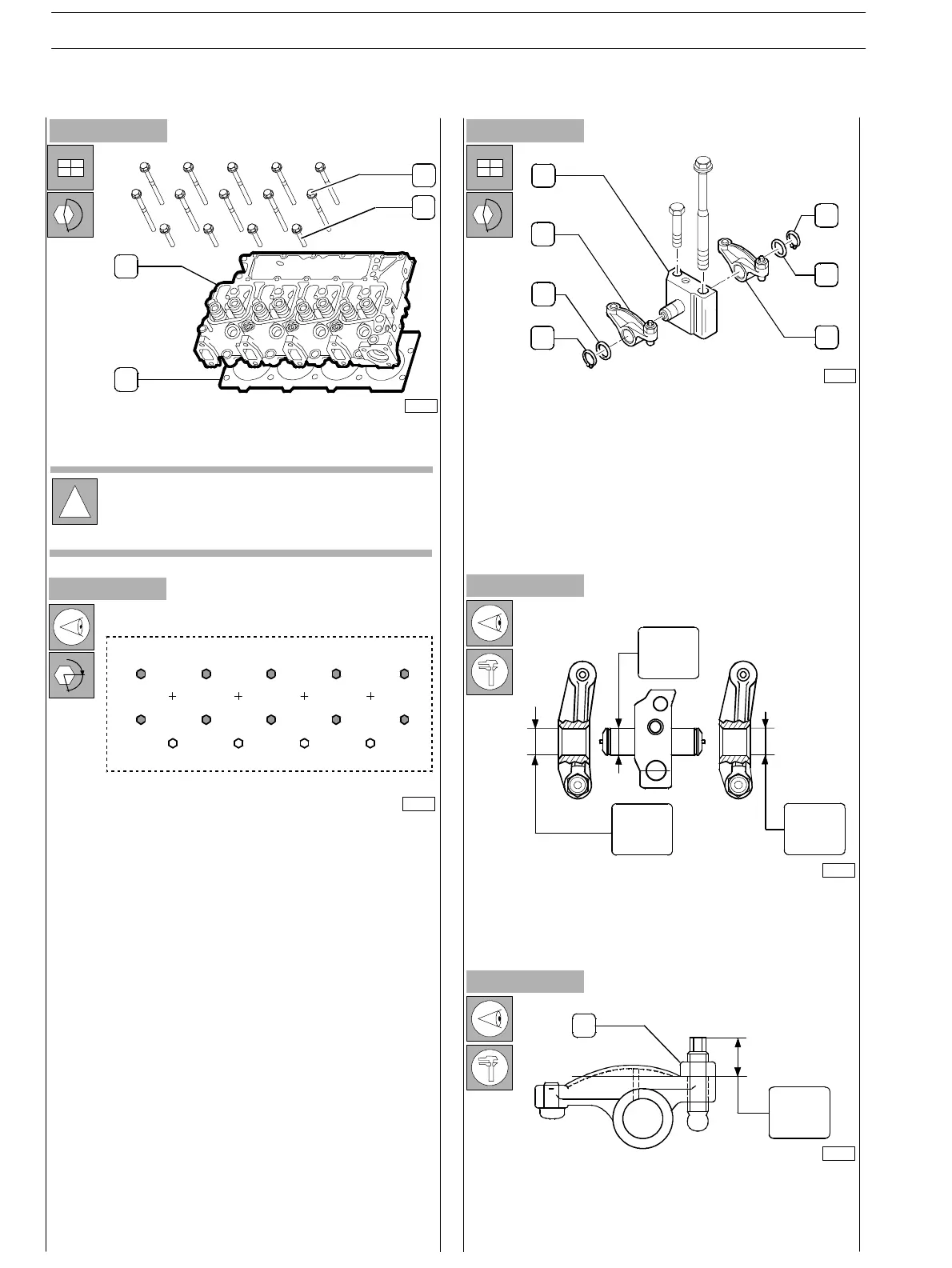

Figure 66

Figure 67

- Place the head (3) over the block and insert screws (1)

and (2).

- Lubricate cylinder head bolts an d install to head.

- Bolts must be torqued using stitching pattern starting

with the c entre bolts and moving out. Bolts to be

torqued in stages: all bolts torqued to snug torque, then

90 degrees rotation for all bolts. Then a further 90

degrees for the M12 x 140 and M12 x 180.

M12 x 70 50 Nm + 90 deg’s

M12 x 140 40 Nm + 180 deg’s

M12 x 180 70 Nm + 180 deg’s

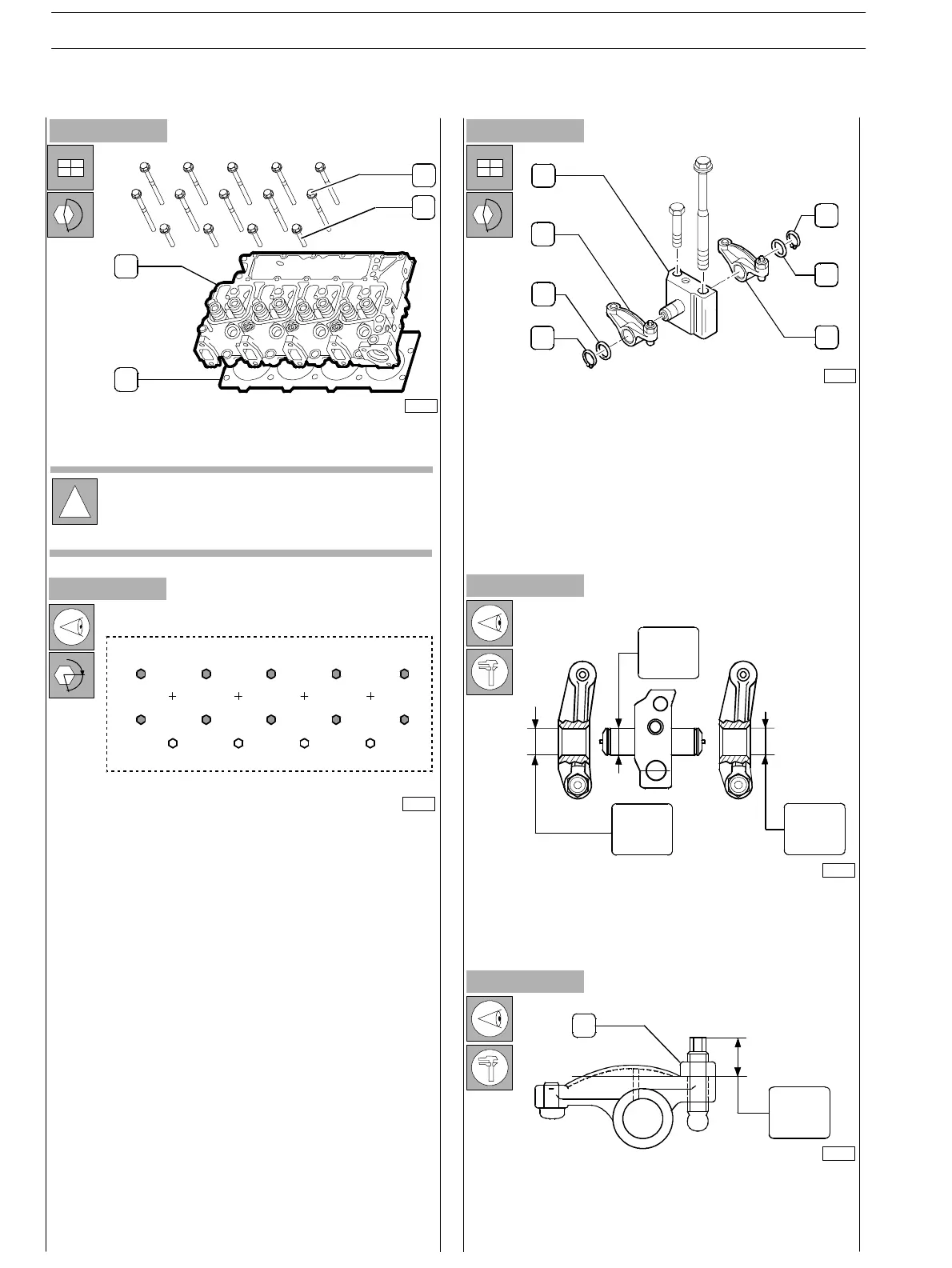

Figure 68

SHAFT AND ROCKER ARM BASIC DATA

Check the coupling surfaces of bearing and shaft: no evidence

of excessive wear shall be detected or damages.

Replace if necessary.

- Carry out the assembly of the rocker arms after previous

check of the components.

Figure 69

!

If the valves have been removed from the head, it is

necessary to assemble them before assembling the

head itself on the engine block.

1

2

3

4

75688

75705

1

2

3

4

1

2

3

ROCKER ARM UNIT COMPONENTS:

1. Elasti c ring − 2. Spacer− 3. Rocker arms−

4. Support.

76115

1

2

3

45

6

7

8

9

10

11

12

13 14

α

75704

18.975

18.963

19.000

19.026

19.000

19.026

1

19.00

16.00

Figure 70

75702

ROCKER ARM ADJUSTMENT SCREW

If unscrewed, check adjustment quota.

Tighten the screw−threaded nut (1) to the i 0.25 − 0.75 Nm

couple.

SECTION 3 − DUTY − INDUSTRIAL APPLICATION

26

E NG I NE S

ED. FEBUARY 2003

zs

Loading...

Loading...