INTRODUCTION

Installationoftaperedthreadconnectors

1.Removeprotectiveconnectorcapsonlyimmediately

priortoassembly.

NOTICE:Pre-appliedsealants,suchasLOCTITE®

503™VIBRA-SEAL®and/orpowderedPTFEarethe

preferredsealantsfortaperedthreadconnectors.

Non-preferredsealanttypesincludePTFEtape,paste

sealants,andanaerobicliquids.PTFEtapeand

pastesealantsmaycontributetohydraulicsystem

contamination.

2.Inspectthecomponentstoensurethatthemaleand

femaleportthreadsandsealingsurfacesarefreeof

burrs,nicks,andscratches,oranyforeignmaterial.

Donotuseifimpuritiesarefound.

3.Applythesealant/lubricanttothemalepipethreads,

ifnotpre-applied.Therstoneortwothreadsshould

nothavesealantappliedtothemtoavoidsystemcon-

tamination.

NOTICE:Ifyourequireaspecicorientationofa

shapedconnector,takeintoconsiderationthatnal

positionbeforeyouproceedwiththenextsteps.

Neverbackoff(loosen)taperedthreadconnectorsto

achievealignmentyouwillincreasethepossibilityof

leaks.

4.Screwtheconnectorintotheporttothengertight

position.

5.Useawrenchtotightentheconnector.Seethetorque

tableforthepropernumberofTurnsFromFingerTight

(TFFT).

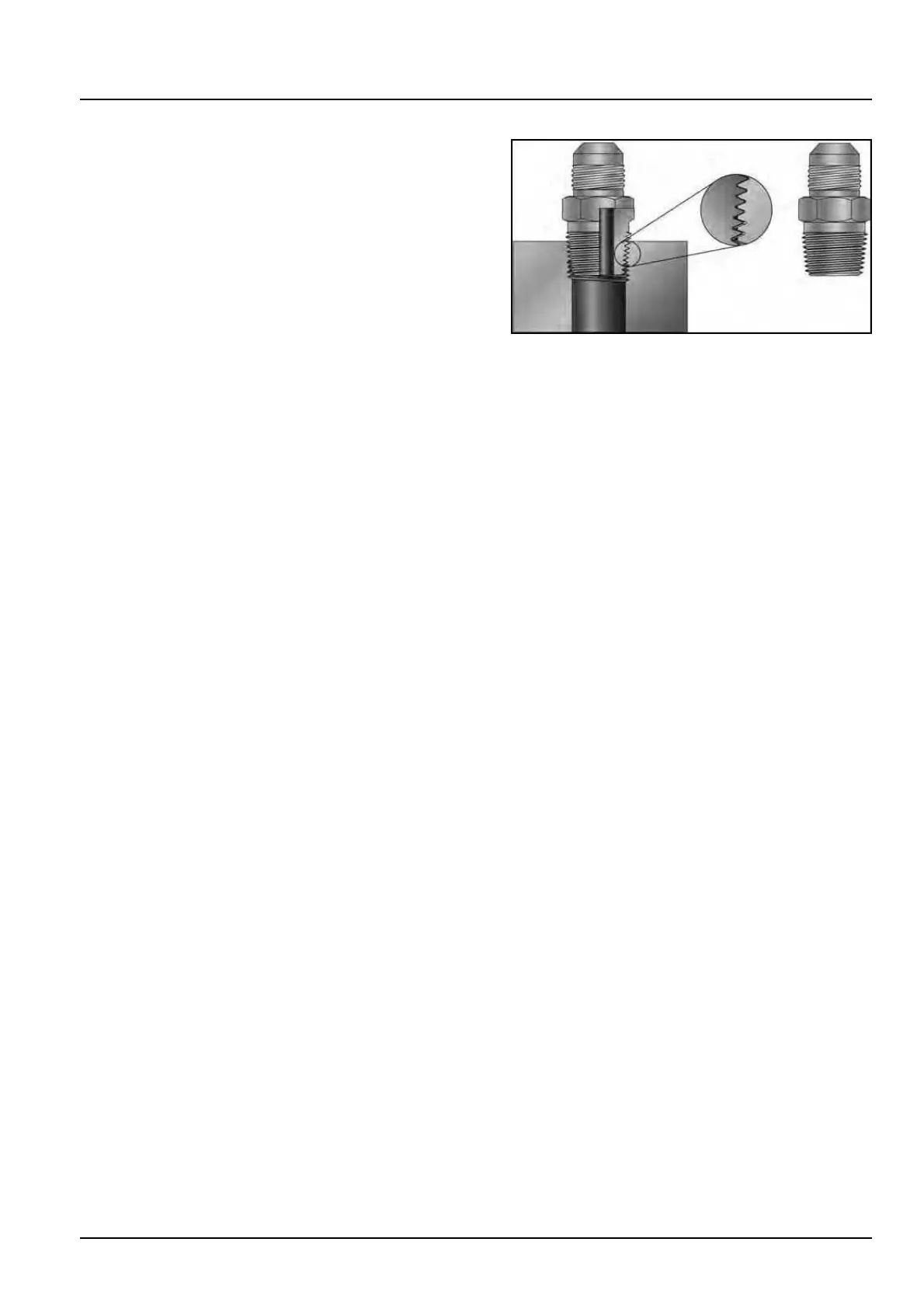

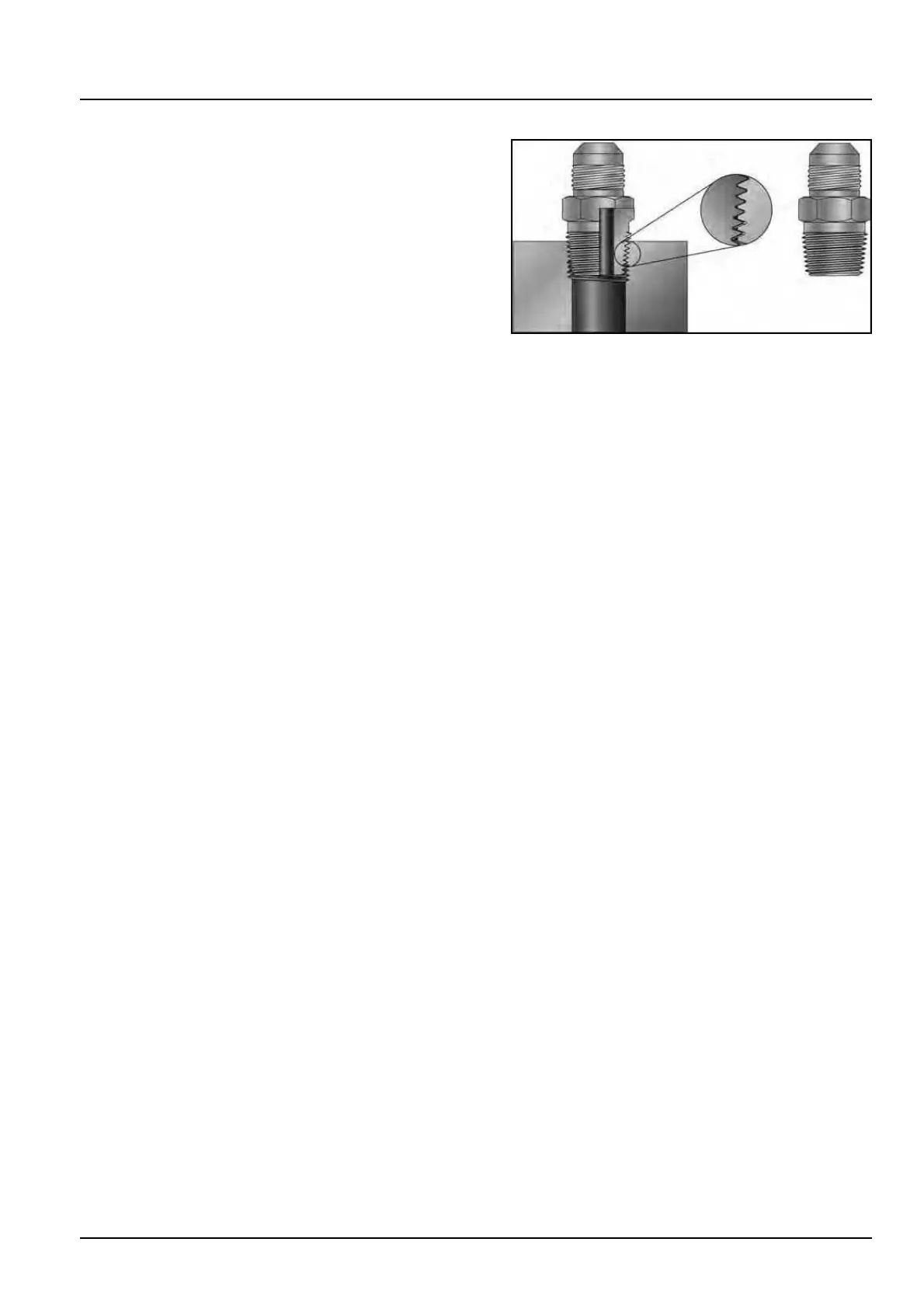

NOTE:Normally,thetotalnumberofthreadsengaged

shouldbebetween3.5and6.Ifmorethan6threads

areengaged,thismayindicatedanover-tightened

connection.Iffewerthan3.5threadsareengaged,

thismayindicateanunder-tightenedconnection.For

anover-tightenedconnection,checkboththreadsand

replacethepartwhichhasout-of-tolerancethreads.If

theconnectionisunder-tightened,itisacceptableto

tightenitfurther,butnomorethanonefullturn.

RAIL15TLB0539AA3

4819455820/10/2017

59

Loading...

Loading...