EFFE4 B - EFFE6 B

- 16 -

EFFE4-6 B_EN - 2010/07 Ed. 05

Water

inlet

WARNING

IThermic exchange fluid is not toxic if swallowed, but it is advisable to anyway handle it

with care. Do NOT touch with bare hands!

In case of contact with eyes, wash with water abundantly.

Do not dispose of it in the drains directly.

Keep it out of children.

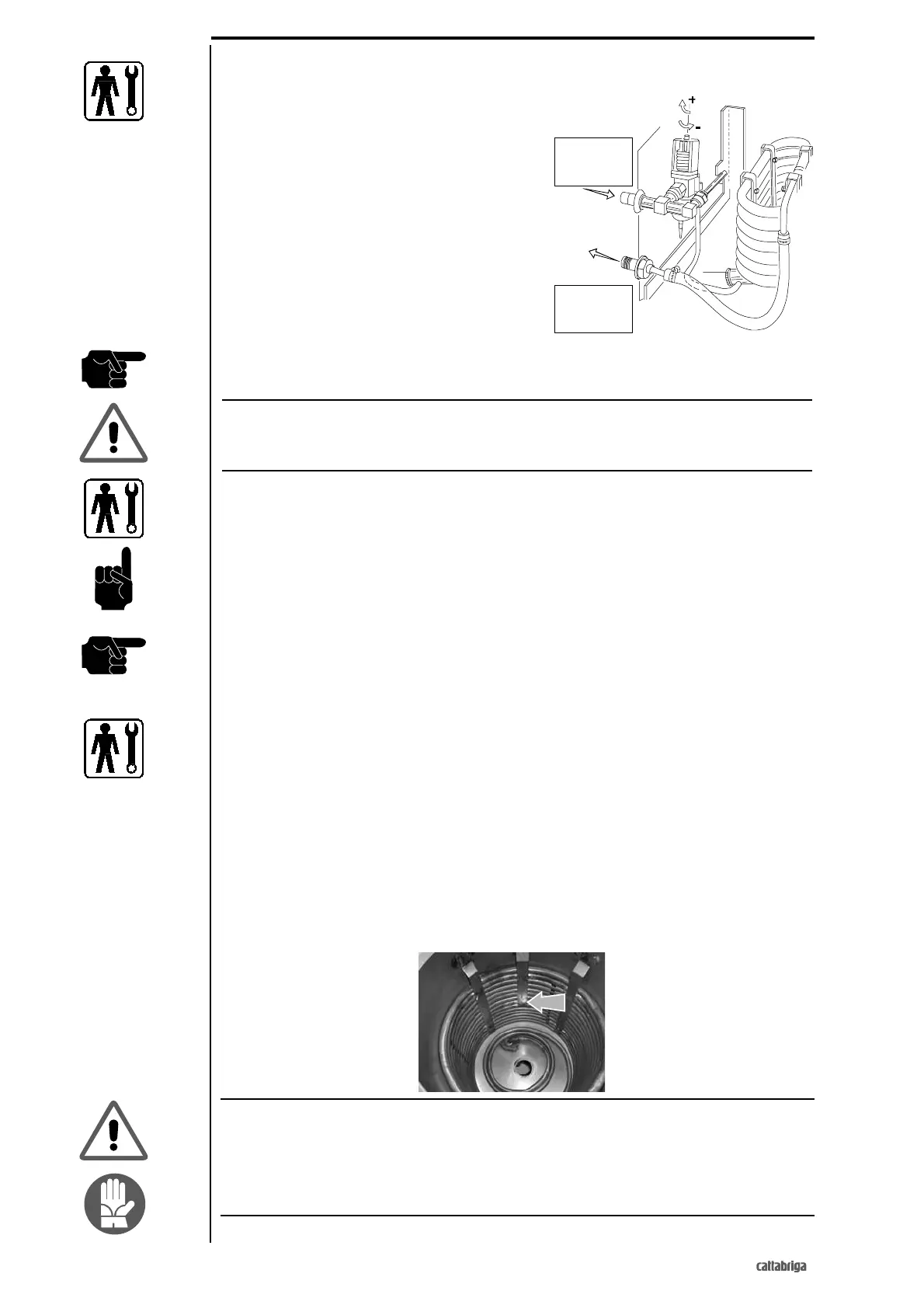

3.2 CONNECTING MACHINES WITH

WATERCOOLED CONDENSER TO WATERMAIN

A watercooled machine can run when only con-

necting it to running water supply or to a cooling

tower.

Water inlet must have a pressure 100 to 800kPa (1 to

8 bar) and a delivery at least equal to the estimated

hourly consumption .

Connect inlet pipe which is marked by the plate

"Entrata Acqua" (Water inlet) to water supply,

installing a shut-off valve, and the outlet pipe which

is marked by the plate "Uscita Acqua" (Water Out)

to a drain pipe, installing a shut-off valve.

Water connections (for gas cooling) are to be found

on rear panels.

NOTE:

We recommend to use rubberized canvas pipes having working pressure up to 800kPa (8bar).

CAUTION

Do not leave the machine in a room with temperature below 0°C without first draining

water from the condenser (see Sect. 7).

3.2.1 Water valve adjustment

IMPORTANT:

The water valve can be reached by removing the rear pane

A possible resetting of water valve must be carried out by skilled personnel, only.

Water valve adjustment must be carried out in such a way that no water flows when the machine

is off and lukewarm water flows when the machine is on.

NOTE:

Water consumption increases if temperature of entering water is above 20°C.

3.3 CHARGING THE THERMIC EXCHANGE FLUID

A thermal exchange fluid is introduced to transmit the cold between the evaporator coil of the

refrigeration installation and the rotating whipping chamber. This thermal exchange fluid is a

mono-propylene glycol inhibitor. This fluid must be diluted in a 50% volume with water. It is

advisable to always use the same type of product that has been tested by CATTABRIGA to ensure

the safety of the machine, its components and the conformity to the machine’s food norms.

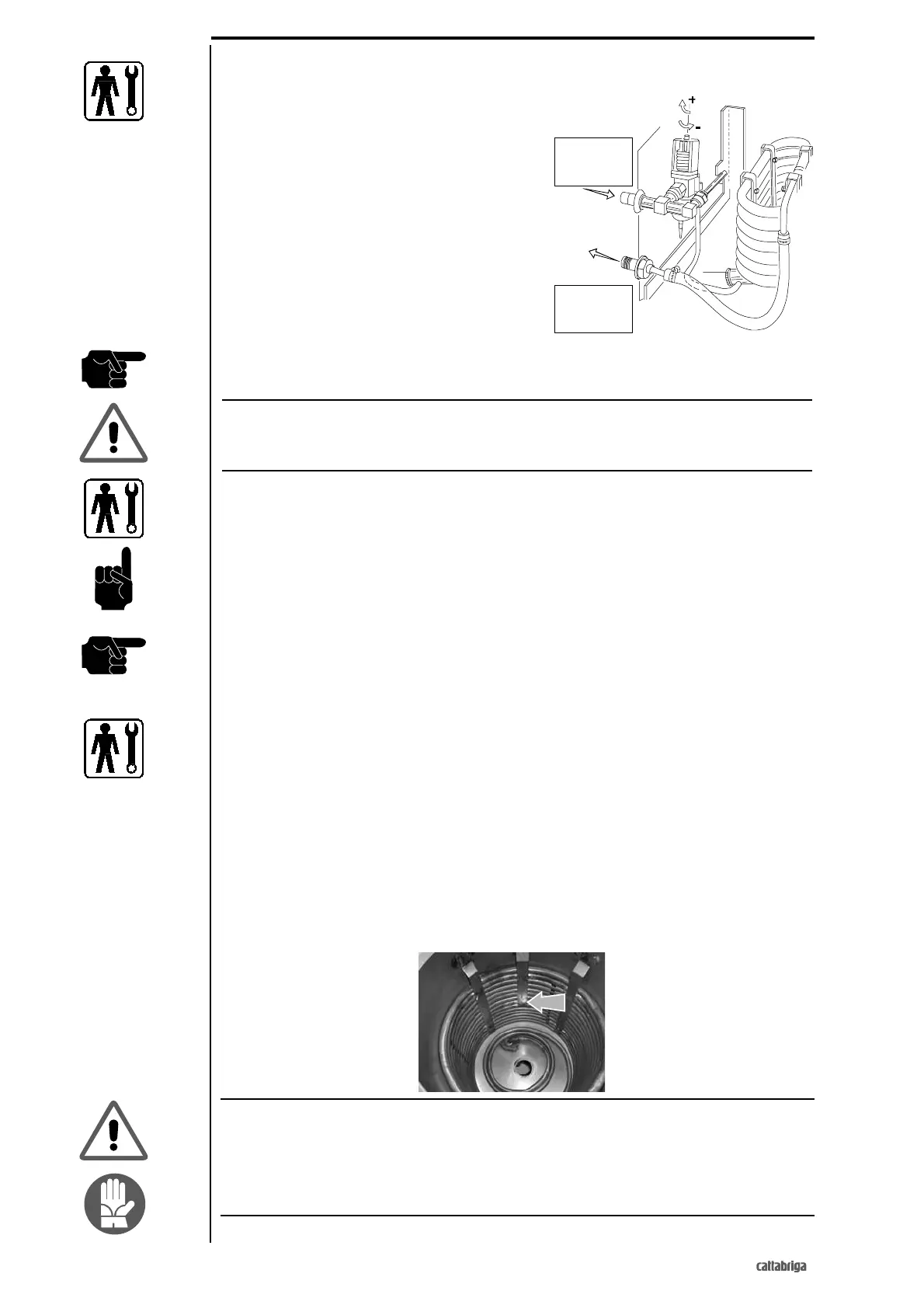

To introduce the special thermal exchange fluid contained in the appropriate container into the

machine, the whipping chamber must be disassembled following the instructions reported in

section 6. Ensure that the front drain plug is in place. The level of fluid necessary is indicated

inside the chamber by a mark highlighted on the evaporator coil (refer to the following figure)

and must arrive underneath the evaporator coil fixing plate.

Place the whipping chamber into its housing and push it downwards. If the thermal exchange

fluid is excessive, it will flow over from the overflow hole dropping into the appropriate oil-drip

drawer positioned on the front of the machine.

Water

Out

Loading...

Loading...