3

■ WELDING MODE

The RAINBOW welding machine offers 3 welding modes. Each

time the button is pushed, the welding machine switches to se-

lect the welding mode indicated by the LED that stays lit, in the

following order:

L4 2 STROKES

L5 4 STROKES

L6 SPOT WELDING

L5

L6

L4

L4 2 STROKES

TIG welding takes place as follows:

WELDING CURRENT (I1)

I

1 (A)

POST GAS

2000HC22/A

t (sec)PRE-GAS

SLOPE UP SLOPE DOWN

L5 4 STROKES

TIG welding takes place as follows:

WELDING CURRENT (I1)

I1 (A)

POST GAS

2000HC22/A

t (sec)PRE-GAS

SLOPE UP SLOPE DOWN

NOTE: Welding only begins when the torch button is pushed.

L6 SPOT WELDING

This can be used by pushing the torch button to spot weld for a pre-

set period of time (in seconds) at the end of which the arc switch-

es off automatically.

■ ENCODER KNOB

This is used to regulate and change the welding parameters, ac-

cording to which LED is switched on and the value shown on the

DISPLAY, which is necessary for the machine to work correctly.

■ WELDING PARAMETERS

Each time the button is pushed, the welding machine selects the

next function according to the machine configuration, the welding

process, the welding mode, etc...

To exit welding parameter programming, hold the T3 button down

for about 1 second.

STANDARD MMA WELDING CONFIGURATION

When using the electrode welding process, this allows you to select

the following welding parameters, based on which LED is flashing:

L7 HOT START

L7

T3

STANDARD TIG WELDING CONFIGURATION

When one of the 2 TIG welding processes available on the welding

machine is activated, this allows you to select the following weld-

ing parameters, based on which LED is flashing:

L7 PRINCIPAL welding CURRENT I1

L8 PRE-GAS duration

L9 SLOPE UP duration

L10 SLOPE DOWN duration

L11 POST-GAS duration

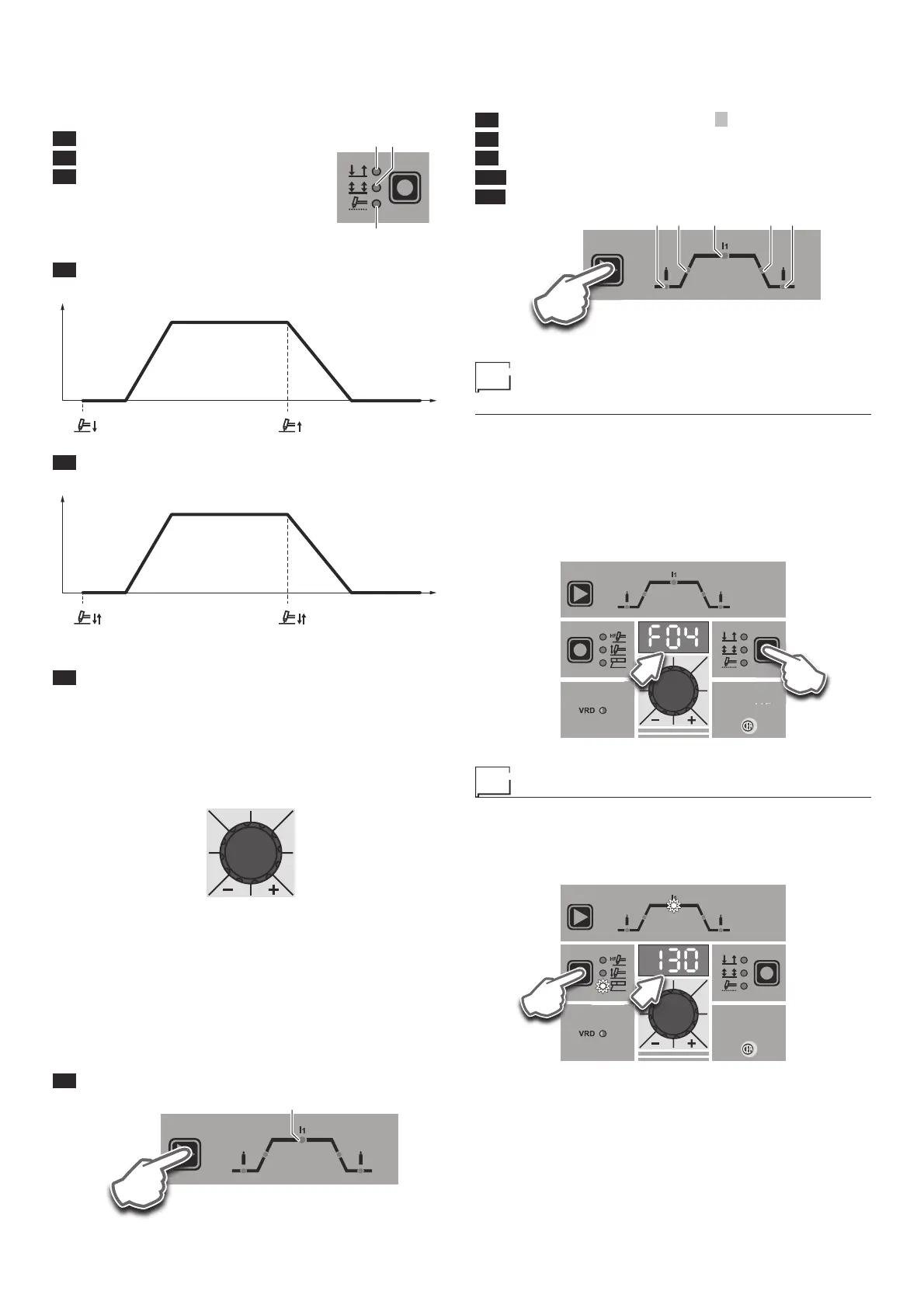

L7 L10 L11L8 L9

T3

Displaying the software

version installed

The RAINBOW HF are fitted with a digital control with software on

board defined in the factory. This software is subject to continuous

evolution and improvement. The software is identified by a spe-

cific number that can be viewed on the DISPLAY (D) as follows:

1) With the welding machine switched on, press and hold down

the WELDING MODE button (T1).

2) The DISPLAY (D) shows the type of version of software in-

stalled.

3) To exit, push and release the WELDING MODE button (T1).

RAINBOW

201 HF

W

T1

D

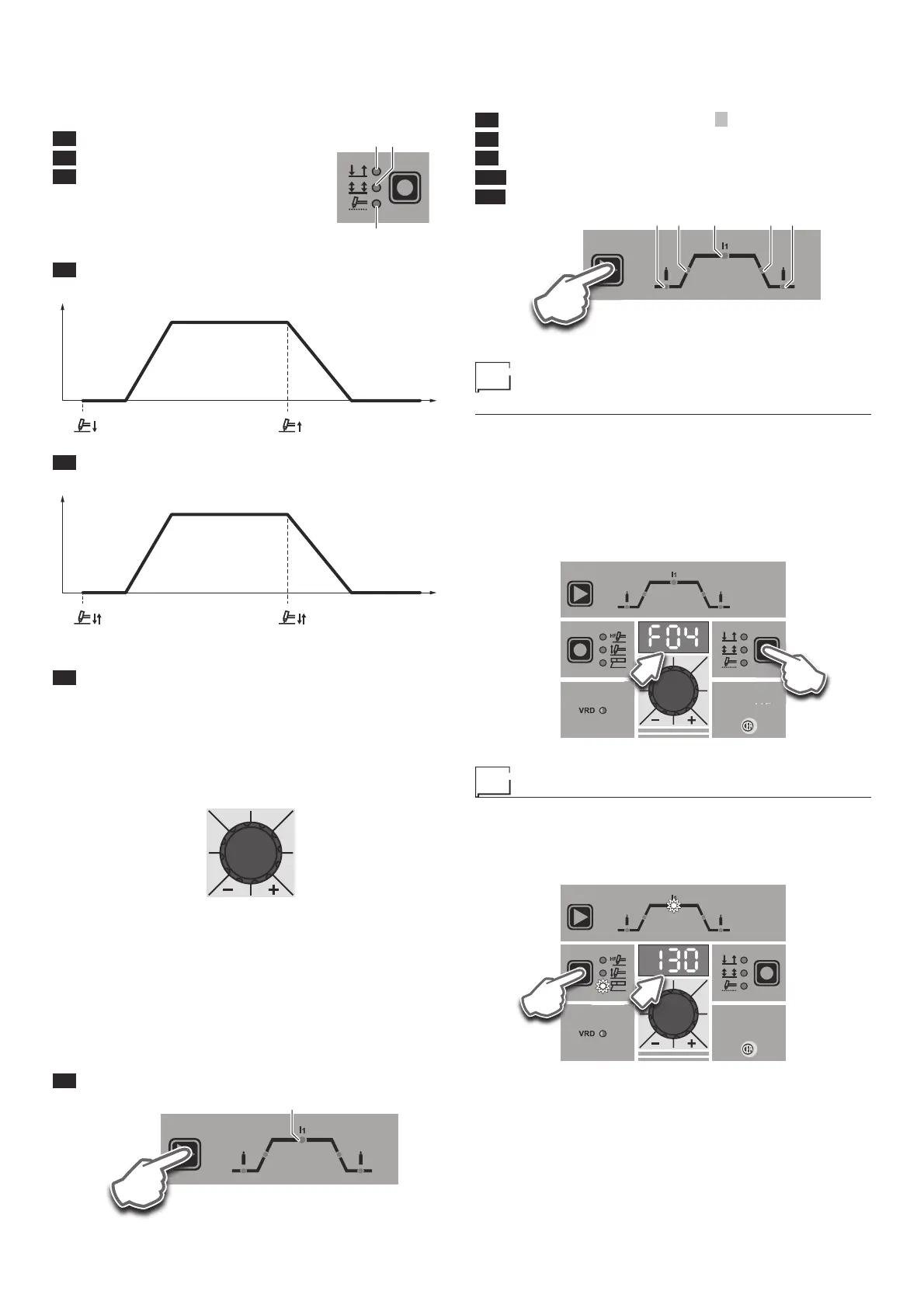

Electrode welding (MMA)

1) Start the welding machine by turning the power supply switch

to position I.

2) WELDING PROCESS SELECTION

Push the WELDING PROCESS SELECTION key (T2) to se-

lect the ELECTRODE welding processes.

RAINBOW

201 HF

T2

D

Loading...

Loading...