11

ENG

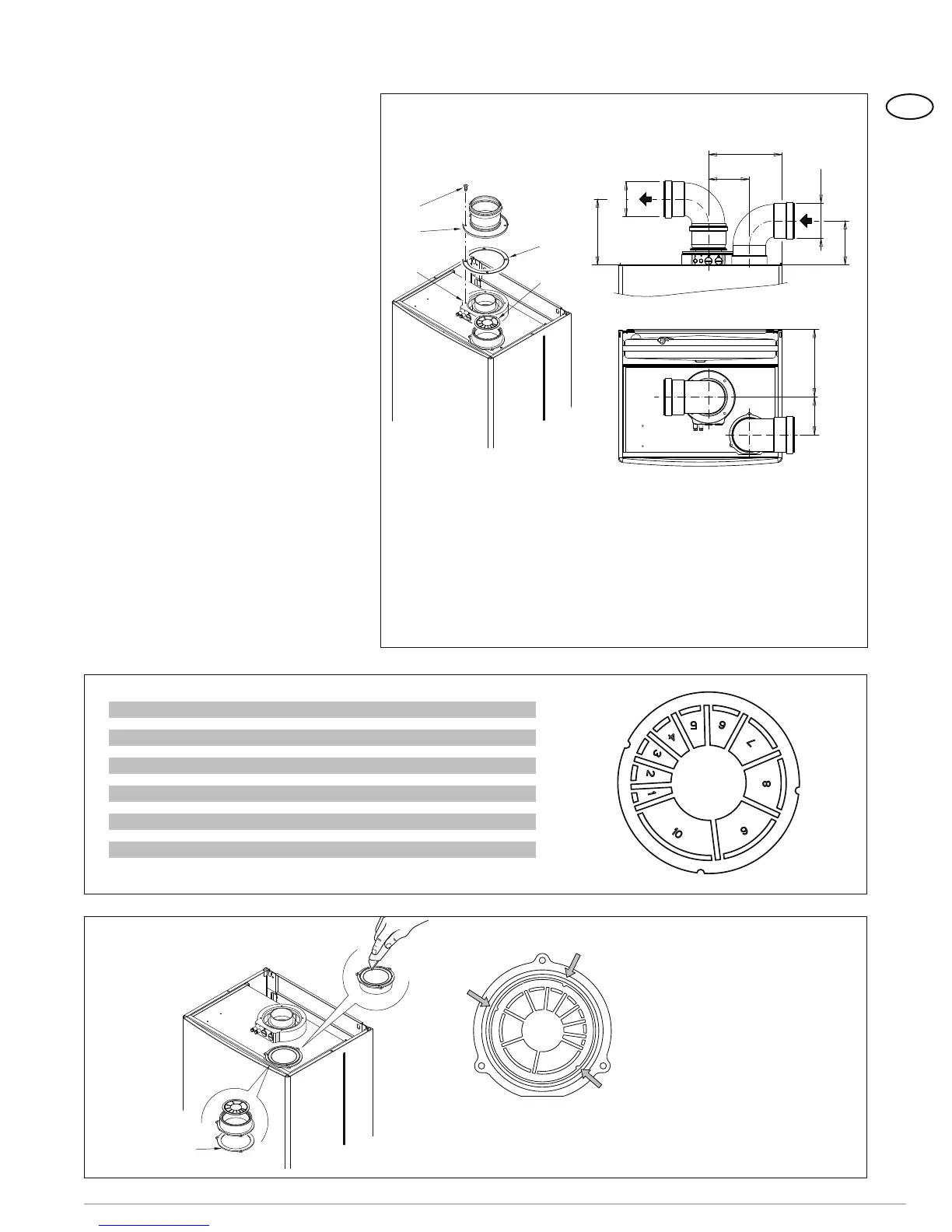

2.7.1 Separate flue kit (fig. 8)

The separate flue kit code 8089909 is sup-

plied with an intake diaphragm which must

be used as shown in fig. 8/a, depending on

the maximum load loss permitted in both

flues. To use the air intake in this type of

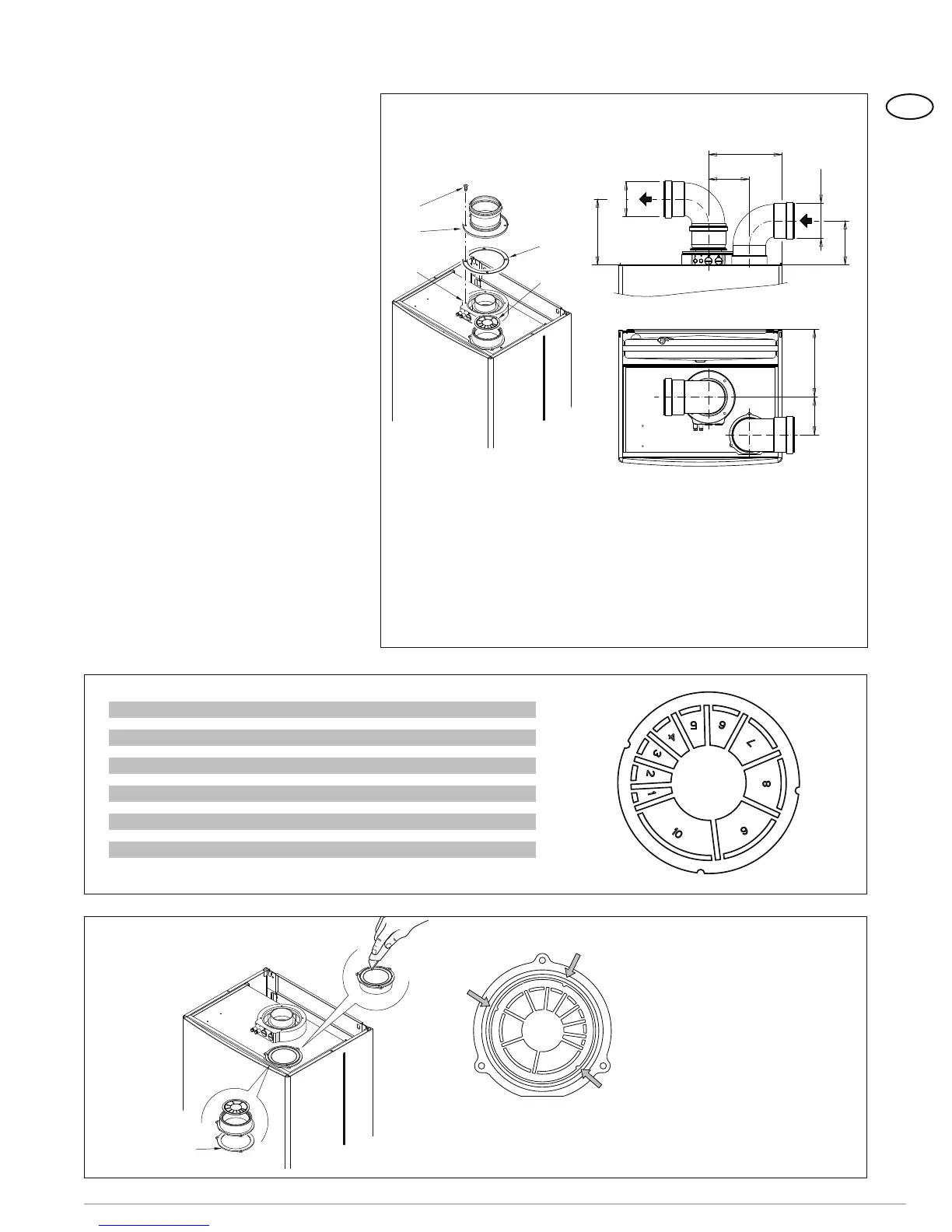

outlet you must perform the following ope-

rations (fig. 9):

1 Remove the base of the air intake, using

a tool to cut it off (a);

2 Overturn the air intake (b) and replace

the seal (5) with the seal supplied in the

kit code 8089909;

3 Insert the intake diaphragm supplied in

the kit code 8089909, pushing it in until

it is in contact with the bottom bead.

You can now insert the extension or curve

in its housing to complete the intake. You

need not use any seal or sealant, as gasket

provided is sufficient.

2.7.2 Outlet systems

The diagrams in fig. 9/a illustrate a num-

ber of examples of different types of sepa-

rate outlets.

2.8 POSITIONING OF OUTLET

TERMINALS (fig. 11)

The outlet terminal must be flush with the

wall and the inlet terminal must protrude

50 mm (2 in) from the outstide wall at

least.

a

b

5

Figure 9

Figure 8/a

N° segments to remove Load loss (mm H

2

O) (“W.C.H

2

O)

n° 1 and 2 0 - 1.0 0 - 0.039

from n° 1 to 3 1.0 - 2.0 0.039 - 0.079

from n° 1 to 4 2.0 - 3.0 0.079 - 0.12

from n° 1 to 5 3.0 - 4.0 0.12 - 0.16

from n° 1 to 6 4.0 - 5.0 0.16 - 0.20

from n° 1 to 7 5.0 - 6.0 0.20 - 0.24

from n° 1 to 8 6.0 - 7.0 0.24 - 0.28

from n° 1 to 9 7.0 - 8.0 0.28 - 0.31

from n° 1 to 10 8.0 - 10.0 0.31 - 0.39

without diaphram 10.0 - 12.0 0.39 - 0.47

IMPORTANT: The three housings

on the diaphragm permit assem-

bly of the air intake in one position

only.

165

110

165

K

ø 80

ø 80

100

92

1

2

3

4

6

Figure 8

KEY

1 (ø 125/95 mm - ø 4.92/3.74 inch) sponge seal

2 Fixing screw

3 Flue outlet flange

4 Inlet air diaphragm

6 Manifold with intakes

205 (8.07”)

100 (3,94”)

(4.33”)

(6,5”)

(ø 3“)

(ø 3“)

(6.5”)

(3.62”)

Loading...

Loading...