25

ENG

4.1 D.H.W. TEMPERATURE

ADJUSTMENT

The system with a potentiometer for adjusting

the temperature of D.H.W. with a setting

range from 30° to 60°C (86-140 °F) offers a

double advantage:

1) The boiler adapts perfectly to any type of

D.H.W. system, whether the mixing system

is a mechanical or a thermostat-controlled

type.

2) The thermal output is dosed according to

the temperature required, which means a

considerable saving in fuel.

NOTE: In order to avoid any misunderstanding

please remember that the value obtained by

the product of temperature difference (in °C)

between D.H.W. output and input into the

boiler by the hourly flow rate measured on the

tap, where hot water is drawn off (l/h), cannot

be higher than the useful output developed by

the boiler.

For measurements and checks on flow rate

and temperature of D.H.W., use suitable

instruments, taking into consideration any

heat dispersion along the stretch of piping

between the boiler and the measuring point.

4.2 ADJUSTMENT OF

D.H.W. FLOW RATE

To adjust the D.H.W. flow rate, use the flow rate

adjuster (5 fig. 5).

Remember that the flow rates and correspon-

ding temperatures of use of hot water have

been obtained by positioning the selector of the

circulation pump on the maximum value.

Should there be any reduction in the D.H.W.

flow rate, the filter installed on the inlet to

the divertor valve (3 fig. 5) will need cleaning.

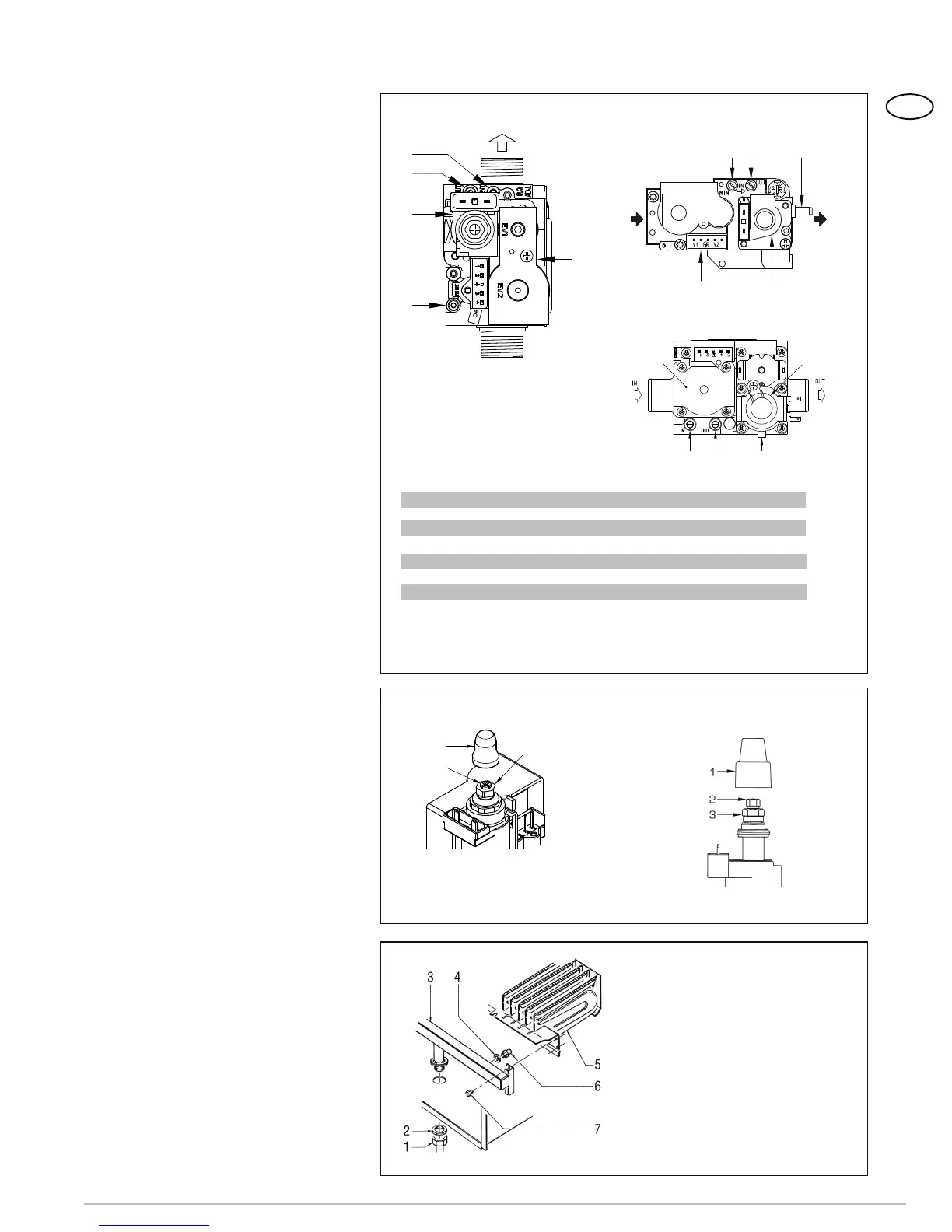

4.3 GAS VALVE

The boilers are equipped standard with the

SIT 845 SIGMA/HONEYWELL VK 4105M /

SIEMENS VGU 50 gas valve (fig. 21).

The gas valve is set at two pressure values:

maximum and minimum. According to the

type of gas burnt, these correspond to the

values given in Table 4.

The gas pressures at the maximum and mini-

mum values, are factory set. Consequently

they must not be altered. Only when you

switch the appliance from one type of gas

supply (methane) to another (propane), it is

permitted to alter the operating pressure.

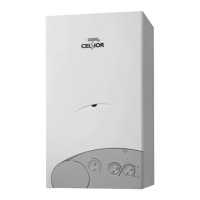

4.4 GAS CONVERSION

This operation must be performed by autho-

rised personnel using original Sime compo-

nents.

To convert from natural gas to LPG or

vice versa, perform the following operations

(fig. 22):

3

2

1

KEY

1 Plastic tap

2 Minimum pressure adjusting nut

3 Maximum pressure adjusting nut

SIT 845 SIGMA HONEYWELL VK 4105M

SIEMENS VGU 50

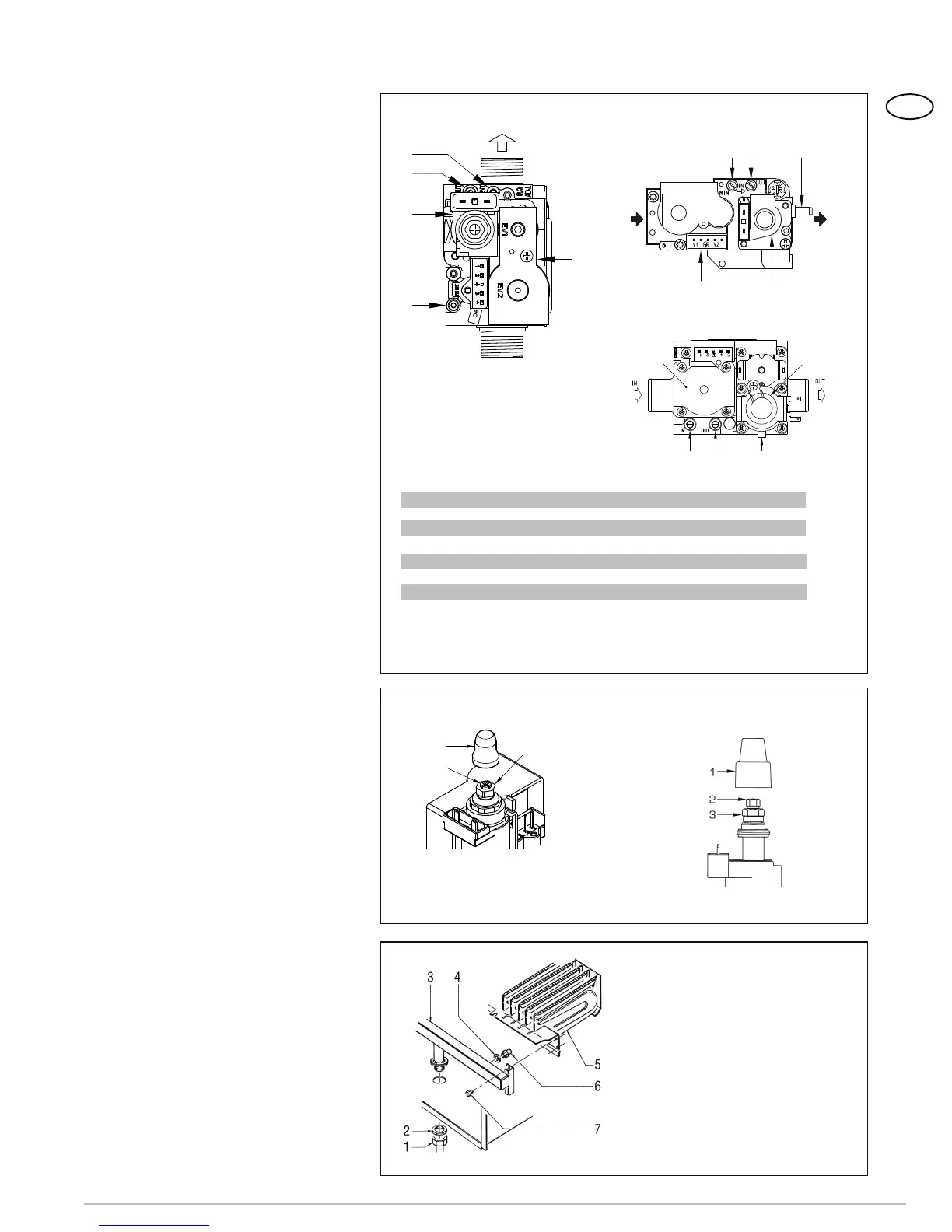

KEY

1 Swivel connection 1/2”

2 Locknut 1/2”

3 Burner manifold

4 Washer ø 6.1

5 Burners

6 Nozzle M6

7 Screw

WARNING: To ensure a perfect seal,

always use the washer (4) supplied in

the kit when replacing nozzles, even in

burner units for which it is not specified.

Figure 22

Figure 22/a

3

4

2

1

5

6

1

2

4

3

5

SIT 845 SIGMA HONEYWELL VK 4105M

KEY

1 Modulator

2 EV1-EV2 coils

3 Pressure inlet upstream

4 Pressure inlet downstream

5 VENT pressure test point

1

2

3 4 5

TABLE 4

Burner maximum pressure Modulator current

Fuel mbar W.C. mA

Natural Gas* 13.7 5.5 130

Propane 24.9 10 165

Burner minimum pressure Modulator current

Fuel mbar W.C. mA

Natural Gas* 5.0 2.0 0

Propane 8.7 3.5 0

(*) Max. burner pressure is guaranteed only when the supply pressure exceeds the max.

burner pressure by at least 3 mbar (1.2” W.C.).

Figure 21

SIEMENS VGU 50

4 USE AND MAINTENANCE

Loading...

Loading...