27

ENG

cleaning the heat exchanger or the bur-

ners, chemical products or steel brushes

MUST NOT BE USED.

Make sure that the tops of the burners

with the holes are free from encrusta-

tions.

4. Reassemble the items removed from the

boiler, making sure to follow the correct

sequence.

5. Check operation of the main burner.

6. After assembly of all the gas connections,

these must be tested for soundness, using

soapy water or appropriate products. DO

NOT USE NAKED FLAMES.

7. Do not use calcium chloride to treat the

plastic component during general mainte-

nance.

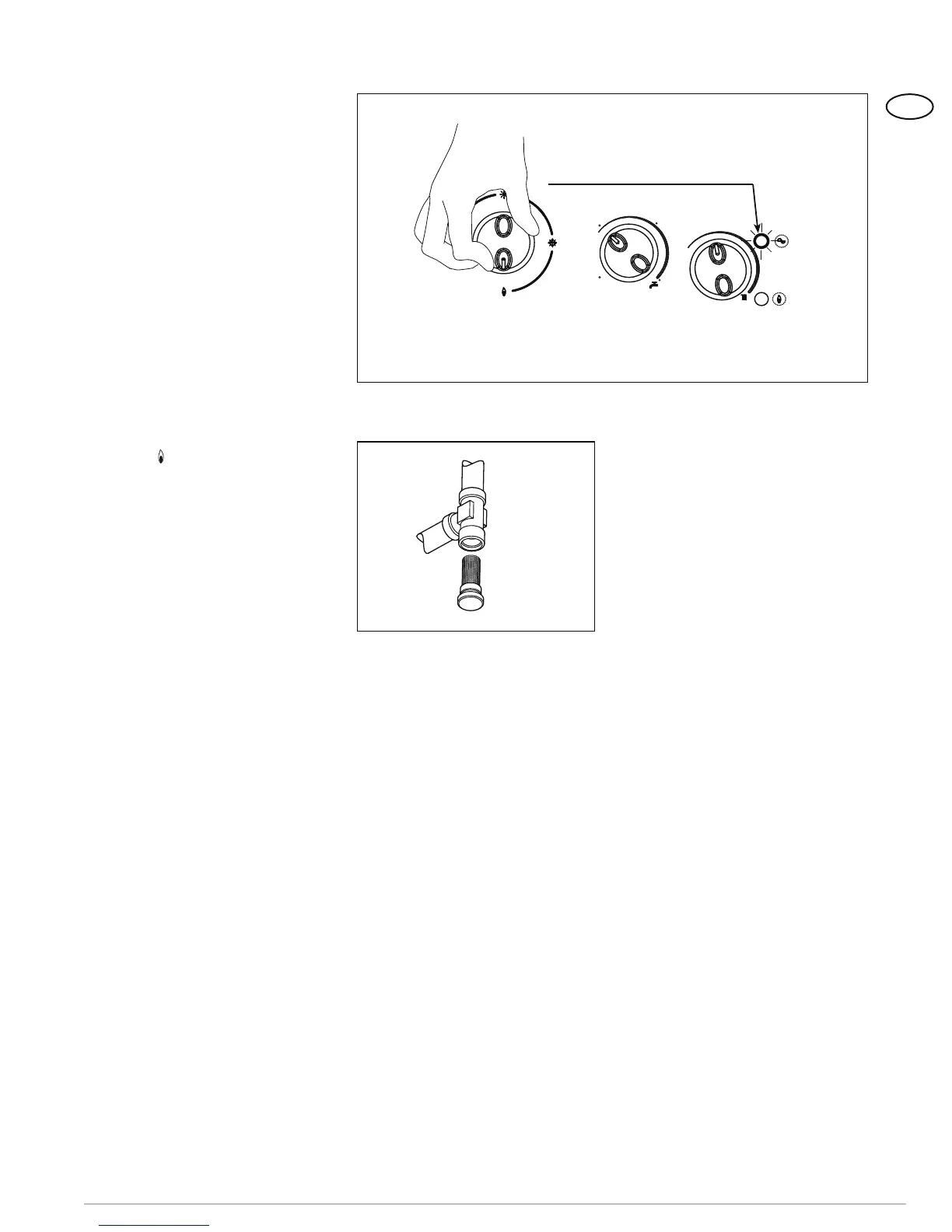

4.6.1 Chimney sweep function (fig. 24)

To carry out the verification of combustion

in the boiler turn the selector and stop on

the position (

) until the green/orange led

starts to flash intermittently.

From that moment the boiler will start fun-

ctioning in heating mode at the maximum

power, with switching off at 80°C (176° F)

and restarting at 70°C (158° F).

Before activating the chimney sweep fun-

ction make sure that the radiator valves

or eventual zone valves are open. The test

may be carried out also during hot-water

service functioning. To do so it is enough,

after having activated the chimney sweep

function, to take some hot water from one

or more taps.

Even in this condition the boiler functions at

the maximum temperature always with the

primary controlled between 80°C ( 176° F)

and 70°C (158° F).

During the entire duration of the testing

the hot water taps must remain open. After

verifying the combustion the boiler should be

switched off by placing the selector on the

OFF position; then return the selector to the

desired function.

ATTENTION: After about 15 minutes, or

once the hot water request has been fulfil-

led, the chimney sweep function automati-

cally deactivates.

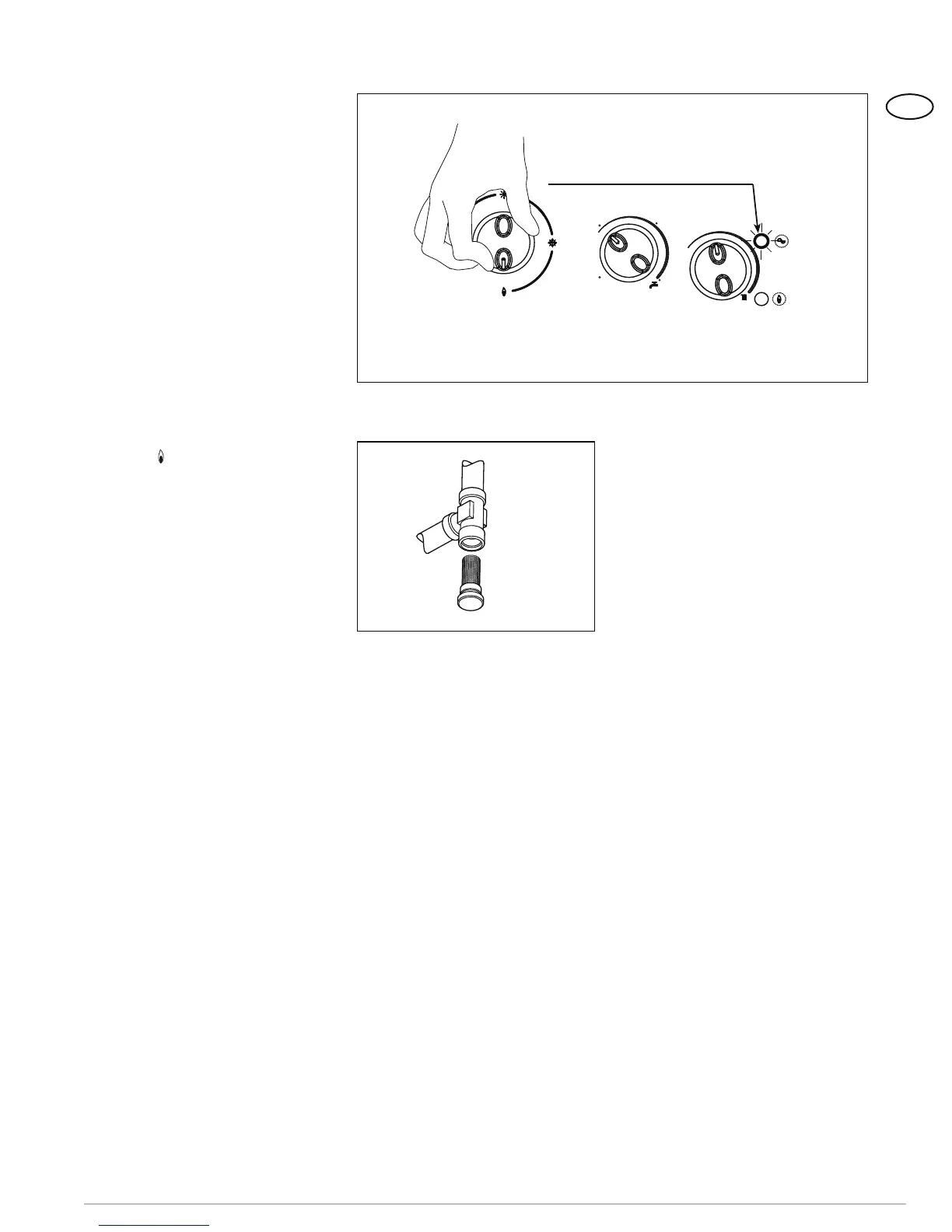

4.6.2 Cleaning the filter “Aqua Guard

Filter System” (fig. 24/a)

To clean the filter, close the delivery/return

on/off taps, turn off the power to the control

panel, remove the casing and empty the boi-

ler using the drain provided.

Place a container for collection underneath

the filter, unscrew the cap and proceed to

clean the filter, removing impurities and lime-

stone deposits.

Check the seal o-ring before reassembling

the cap with the filter.

4.6.3 Venting maintenance

The venting system shall be visually inspected

for deterioration or deposits every 6 months it

is recommended to periodically inspected the

intake and the exhaust terminal for debris or

snow removed from blocking the termination.

Any dirt within the vent shall be removed with

a soft brush.

4.6.5 Fan and pump

The pump and fan don’t need any lubrification.

4.7 FAULT FINDING

The burner does not ignite and the circula-

tor is working.

1. Check that the water pressure reads 1 -

1.2 bar (14.5-17.4 psi).

2. The flowmeter is faulty, replace it.

3. The flow switch has been tripped because

the heating circuit filter “Aqua Guard Filter

System” is obstructed with impurities; it

needs cleaning.

Main burner does not start either to draw

off D.H.W. or for heating.

1. Check flowmeter; if necessary, replace it.

2. Check whether electric power is reaching

the gas valve actuator; check its operation

and, if necessary, replace it.

3. Check operation of the smoke pressure

switch.

4. The fan is operating but at low rpm, so fai-

ling to activate the smoke pressure switch;

replace the fan.

5. Replace the electronic card.

Boiler turns on, but after 10 seconds “locks

out”.

1. Check that during electric wiring the posi-

tion of line and neutral have not been inver-

ted.

2. The ignition/sensing electrode is faulty; re-

place it.

3. The control box is faulty; replace it.

Gas valve fails to modulate in D.H.W. and

C.H. modes.

1. The sensor is interrupted; replace it.

2. The modulator has a break in winding; replace

it.

3. Check that the current to the modulator

complies with the specifications.

4. The control box is faulty; replace it.

Boiler is noisy or heat exchanger makes a

sizzling sound.

1. Check whether circulation pump P is ob-

structed; if necessary clear it out.

2. Unclog impeller of circulation pump, clea-

ring away any impurities or sediments.

3. Circulation pump is burnt out or has a lower

rpm than required; replace it.

4. Check boiler output is adequate for actual

needs of heating system.

Boiler safety valve keeps tripping.

1. Flush the safety relief valve to remove any

sediment or debrit and ensure a proper val-

ve seal. If it doesn’t close properly, replace it.

2.

Check system cold charge pressure is not too

high;

keep to recommended values.

3. Check whether safety valve is out of calibra-

tion; if necessary, replace it.

4. Check whether the vessel is sufficiently capa-

cious to contain the water for the system.

5. Check preloading pressure of expansion

vessel.

6. Replace expansion vessel if faulty.

Figure 24/a

Spia lampeggiante

verde/arancio

2

4

5

3

Figure 24

FLASHING

GREEN/ORANGE LED

Loading...

Loading...