22

ENG

3.1 ELECTRONIC BOARD

The electronic boards are manufactured in

compliance with the ANSI and Canadian direc-

tives.

They are supplied with 120V and, throu-

gh a built-in transformer, send a voltage of

24V to the following components: modula-

tor, D.H.W./C.H. sensors, room stat, water

flowmeter/water pressure switch, pressure

switch valve, flue gas thermostat/flue gas

pressure switch, safey thermostat and time

programmer.

An automatic and continuous modulation

system enables the boiler to adjust the heat

output to the various system requirements or

the User’s needs.

The electronic components are guaranteed

against a temperature range of 0° to

+60°C (32°-140° F)

3.1.1 Fault finding

The indicator leds signalling irregular and/

or incorrect operation of the equipment are

indicated in fig. 14.

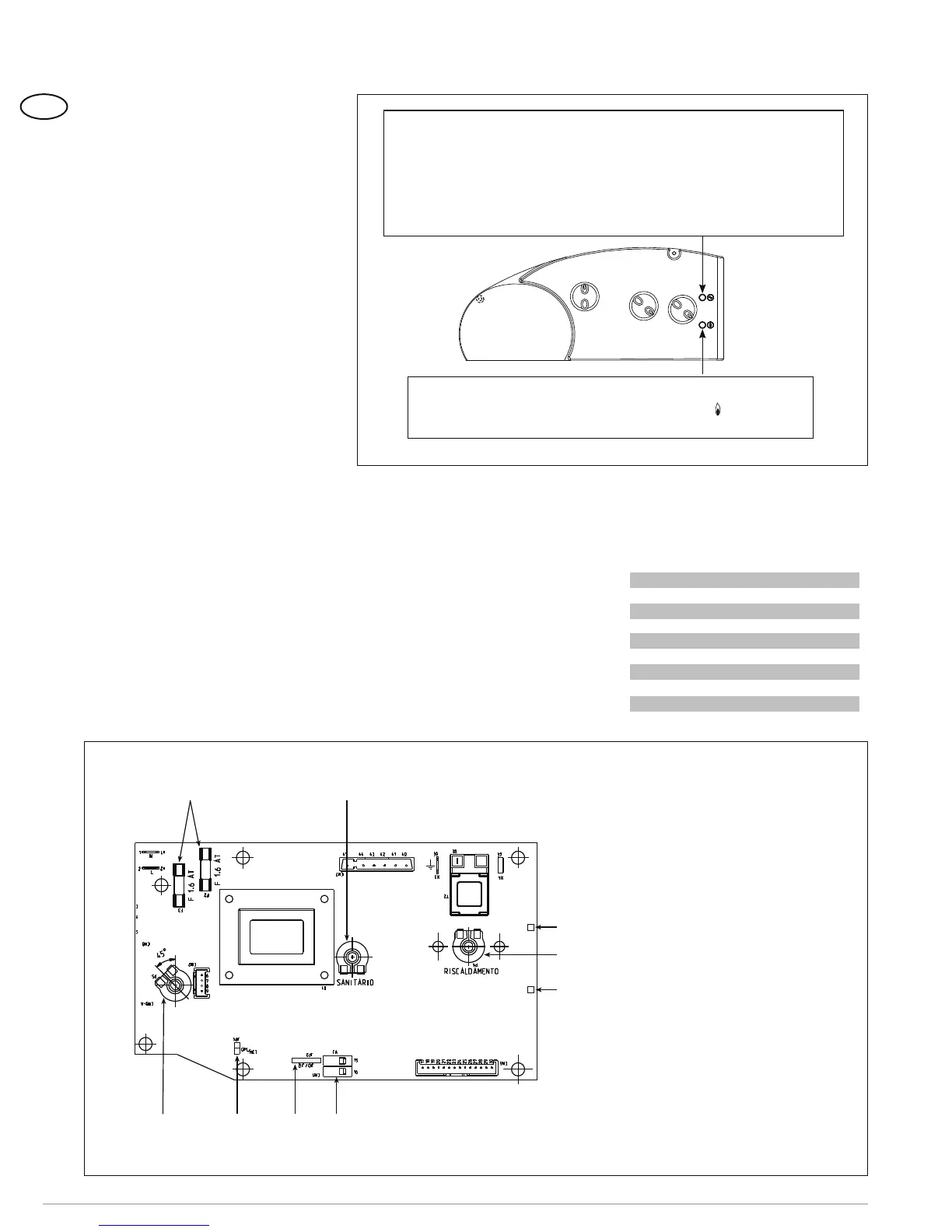

3.1.2 Devices

The electronic board is equipped with the

following devices (fig. 15):

– Connector “METANO-GPL” (4)

With the connector disconnected, the boiler

is ready to function with METHANE; with the

connector connected with GPL.

ATTENTION: It is essential that the ope-

rations described above be carried out by

authorized technical staff.

3.2 TEMPERATURE

SENSOR

Antifreeze system made up of the NTC hea-

ting sensor that activates when the water

temperature reaches 6°C (43 F).

The sensor acts as a limit stat, switching-off

the burner when the temperature measured

is higher than 85°C (185 F); the reset tempe-

rature is set at 80°C (176 F).

When sensor has tripped, the boiler will not

function for either service.

Table 3 shows the resistance values ( ) that

are obtained on the sensor as the tempera-

ture varies.

1

2

1045

3

7

8

9

Figure 15

KEY

1 Jumper JP2

2 Fuse (1,6 AT)

3 D.H.W. potentiometer

4 Connector “METHANE/GPL”

5 Rotay switch

7 Block red led

8 C.H. potentiometer

9 Bi-colour led gree/orange

10 Connector “TA”

Figure 14

Red led on, ignition blocked/safety stat tripped:

turn the rotary switch in the position ( )

to restore functioning

3 CHARACTERISTICS

Bi-colour green led off if power is cut-off.

Bi-colour orange led: C.H. sensor (SM) fault.

Green led flashing: fan/smoke pressure switch/smoke stat failure.

Orange flashes on water circulation.

Flashing red led indicates a problem in the tap water probe (SS)

TABLE 3

Temperature Resistance

°C °F (Ω)

20 68 12.090

30 86 8.313

40 104 5.828

50 122 4.161

60 140 3.021

70 158 2.229

80 176 1.669

Loading...

Loading...