23

ENG

3.3 ELECTRONIC IGNITION

Ignition and flame detection is controlled by

an electrode located on the burner. These

guarantee maximum safety with intervention

times, for accidental switching off or gas failu-

re, of within one second.

3.3.1 Operating cycle

Rotate the rotary switch to summer or winter,

the red led should light up.

Burner ignition normally takes place within 10

seconds. However, it is possible for ignition failu-

res to occur, with consequent activation of signal

indicating that the control box has “locked out”.

– Gas failure

The control box runs through the cycle nor-

mally sending electric power to the ignition

electrode. The electrode continues spark

discharge for a maximum of 10 sec. If the

burner does not ignite, the control box “locks

out”.

This may occur upon first ignition or after long

periods of boiler lay-off when there is air in the

pipes. It may be caused by the gas cock being

closed or by one of the valve coils having a

break in the winding, so that the valve cannot

open.

– Ignition electrode fails to spark

In the boiler, only the gas to the burner is seen

to open. After 10 sec. the control box “locks

out”.

This may be due to a break in the wire of the

electrode or to the wire not properly fastened

to the electric terminal of the ignition transfor-

mer.

The electrode is earthed or very worn and

needs to be substituted. The control box is

defective.

When there is a sudden voltage failure, the bur-

ner shuts out immediately; when power supply

returns, the boiler will start up again automa-

tically.

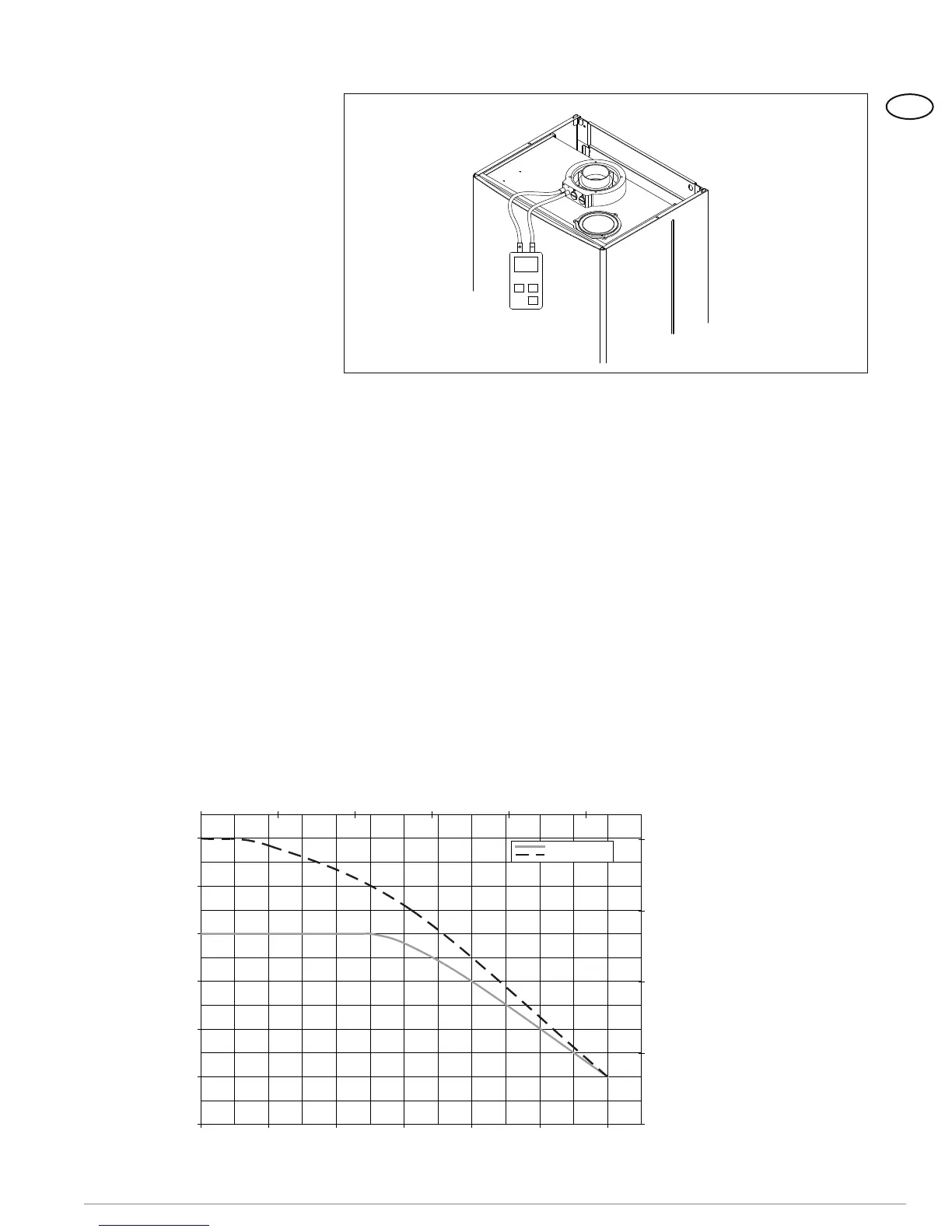

3.4 SMOKE PRESSURE

SWITCH

(fig. 16)

The pressure switch with fixed settings: 4.6-5.6

mmH

2

O (0.18-O.22 ”W.C.H

2

O), is able to gua-

rantee the boiler operation even with air intake

and smoke outlet pipes at the maximum limit of

the length allowed.

The value of the signal to the pressure switch

is measured by means of a manometer con-

nected as shown in fig. 16.

3.5 FLOW SWITCH SAFETY VALVE

The flow switch (8 fig. 5) is tripped and stops

the burner when it does not detect water flow

in the primary circuit > 400 l/h (1.76 USgpm).

To restore burner functioning, check system

pressure and the functioning of the pump and

the flow switch, and the cleaning of the “Aqua

Guard Filter System” filter.

NOTE: If replacing the flow switch valve, make

sure that the arrow stamped on the valve

points in the same direction as the flow of

water.

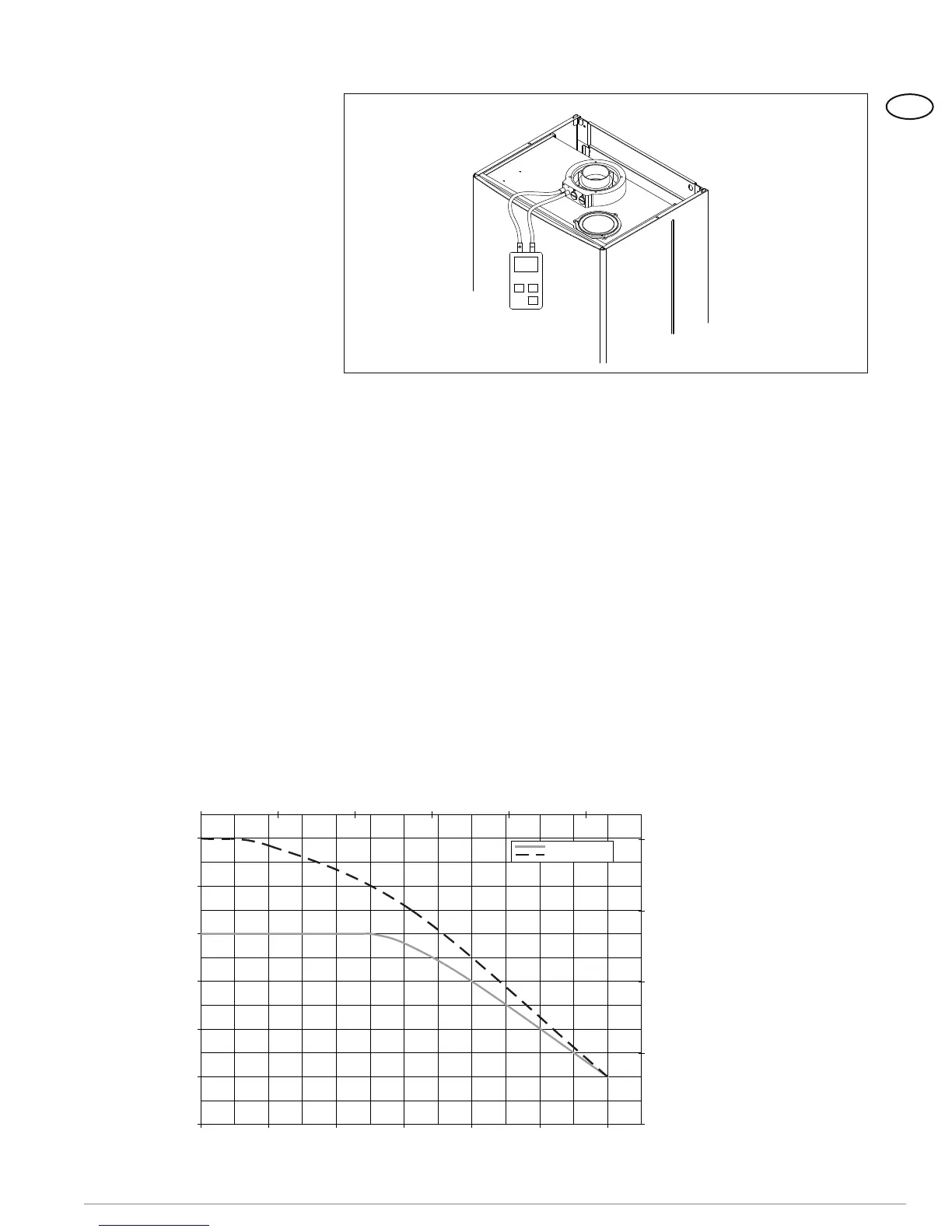

3.6 HEAD AVAILABLE TO SYSTEM

Residual head for the heating system is shown

as a function of rate of flow in the graph in fig.

17.

Figure 16

Figure 17

RESIDUAL HEAD VERSUS FLOW FOR HEATING SYSTEM

0

100

200

300

400

500

600

0 200 400 600 800 1000 1200

Loading...

Loading...