CG Drives & Automation,01-5326-01r5 Functional Description 131

Stop Mode [33B]

When the AC drive is stopped, different methods to come to

a standstill can be selected in order to optimize the stop and

prevent unnecessary wear. Stop Mode sets the way of

stopping the motor when a Stop command is given.

Communication information

11.5.4 Mechanical brake control

The four brake-related menus [33C] to [33F] can be used to

control mechanical brakes e.g. to handle basic hoisting

functions. When hoisting a load generally a mechanical

brake holds the load when the AC drive is not running. To

prevent the load from falling down a holding torque must be

initiated before the mechanical brake is released. On the

other hand when stopping hoisting the brake must be

activated before the holding torque is removed.

Support is included for a Brake Acknowledge signal via a

digital input. It is monitored using a brake fault time

parameter. Additional output and trip/warning signals are

also included. The acknowledge signal is either connected

from the brake contactor or from a proximity switch on the

brake.

The brake acknowledge signal can also be used to improve

safety by preventing hoist falling load in case the brake is not

engaged when stopping.

Brake not released - Brake Fault trip

During start and running the brake acknowledge signal is

compared to the actual brake output signal and if no

acknowledge, i.e. brake not released, while brake output is

high for the Brake Fault time [33H], then a Brake trip is

generated.

Brake not engaged - Brake Warning

and continued operation (keep

torque)

The brake acknowledge signal is compared to the actual

brake output signal at stop. If acknowledge is still active, i.e.

brake not engaged, while brake output is low for the Brake

Engage time [33E] then a Brake warning is generated and

the torque is kept, i.e. prolonging normal brake engage

mode, until brake closes or an emergency action is needed

by the operator, such as setting down the load.

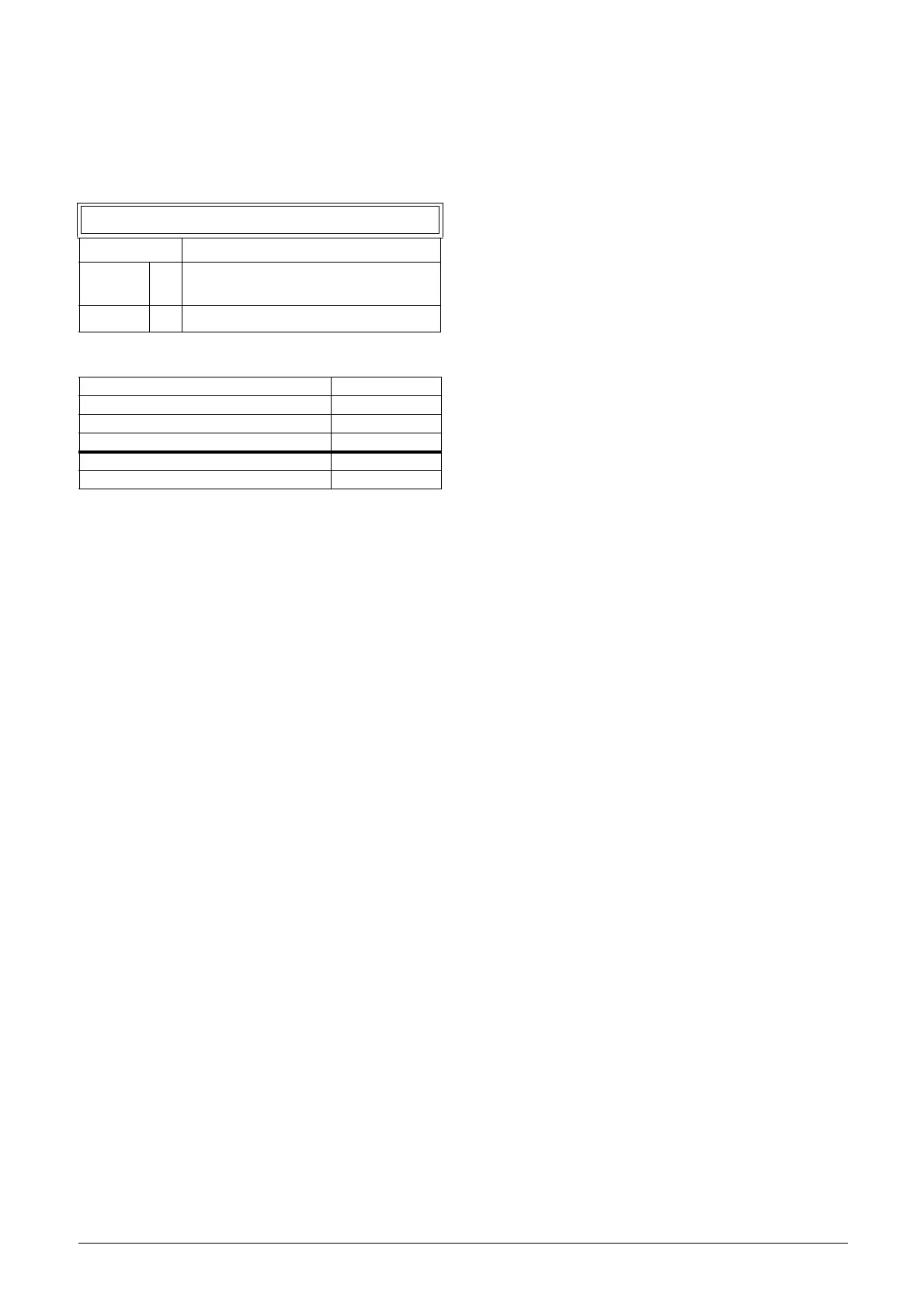

33B Stop Mode

Default: Decel

Decel 0

The motor decelerates to 0 rpm according

to the set deceleration time.

Coast 1 The motor freewheels naturally to 0 rpm.

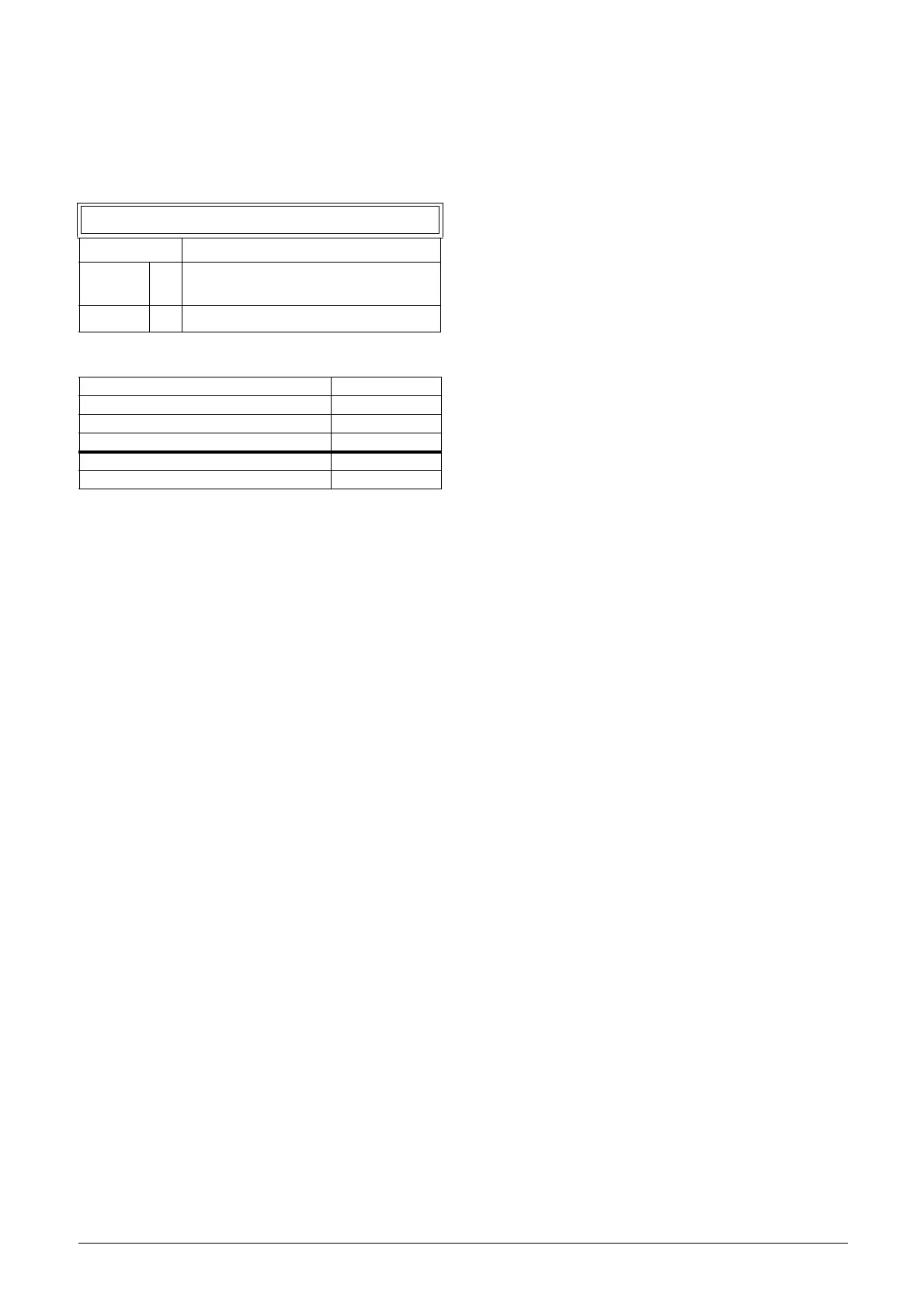

Modbus Instance no/DeviceNet no: 43111

Profibus slot/index 169/15

EtherCAT and CANopen index (hex) 4c27

Profinet IO index 19495

Fieldbus format UInt

Modbus format UInt

Loading...

Loading...