7

TWO STAGE AIR COMPRESSORS - MODEL PL70A

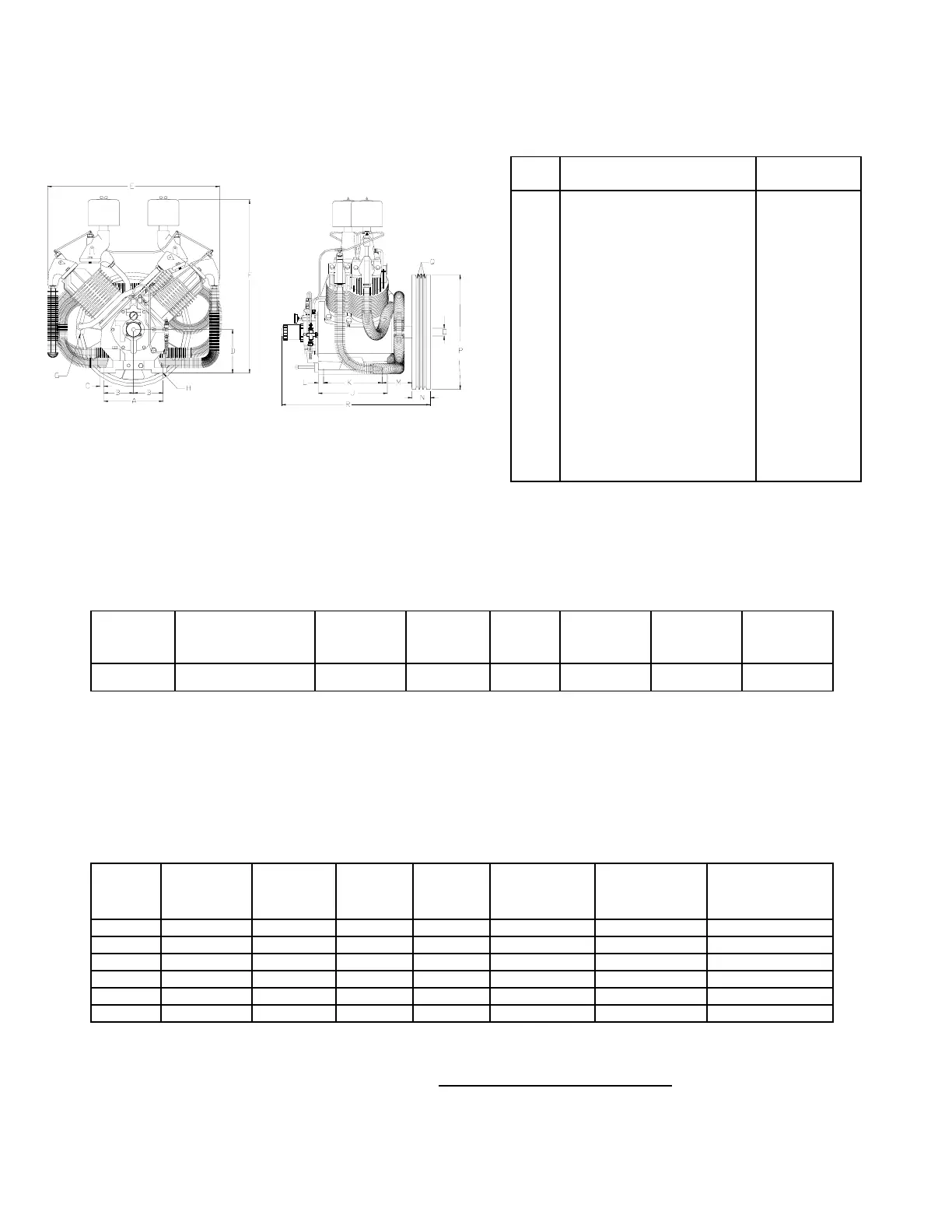

DIMENSIONS

ITEM PL70A

A

B

C

D

E

F

G

H

J

K

L

M

N

O

P

Q

R

Base-Width

Bolt Down-Width

(from center line)

Bolt Down to Edge

Base to Crank Ctr

Overall Width

Overall Height

HP Exhaust Opening

Bolt Down Hole Dia.

Base-Depth

Bolt Down Depth

Bolt Down to Edge

Bolt Hole to Wheel (Max.)

Flywheel Width

Crank Diameter

Flywheel Diameter

Flywheel Grooves

Overall Depth

12-7/8”

5-11/16”

3/4”

8-3/16”

33”

33-9/16”

1-1/4NPT

9/16”

13-1/4”

11-1/4”

1”

5-3/4”

3-1/2”

2-1/4”

22”

3VB

28-9/16”

NOTE:

Flywheel Rotation – Clockwise when viewed

from front, flywheel to rear.

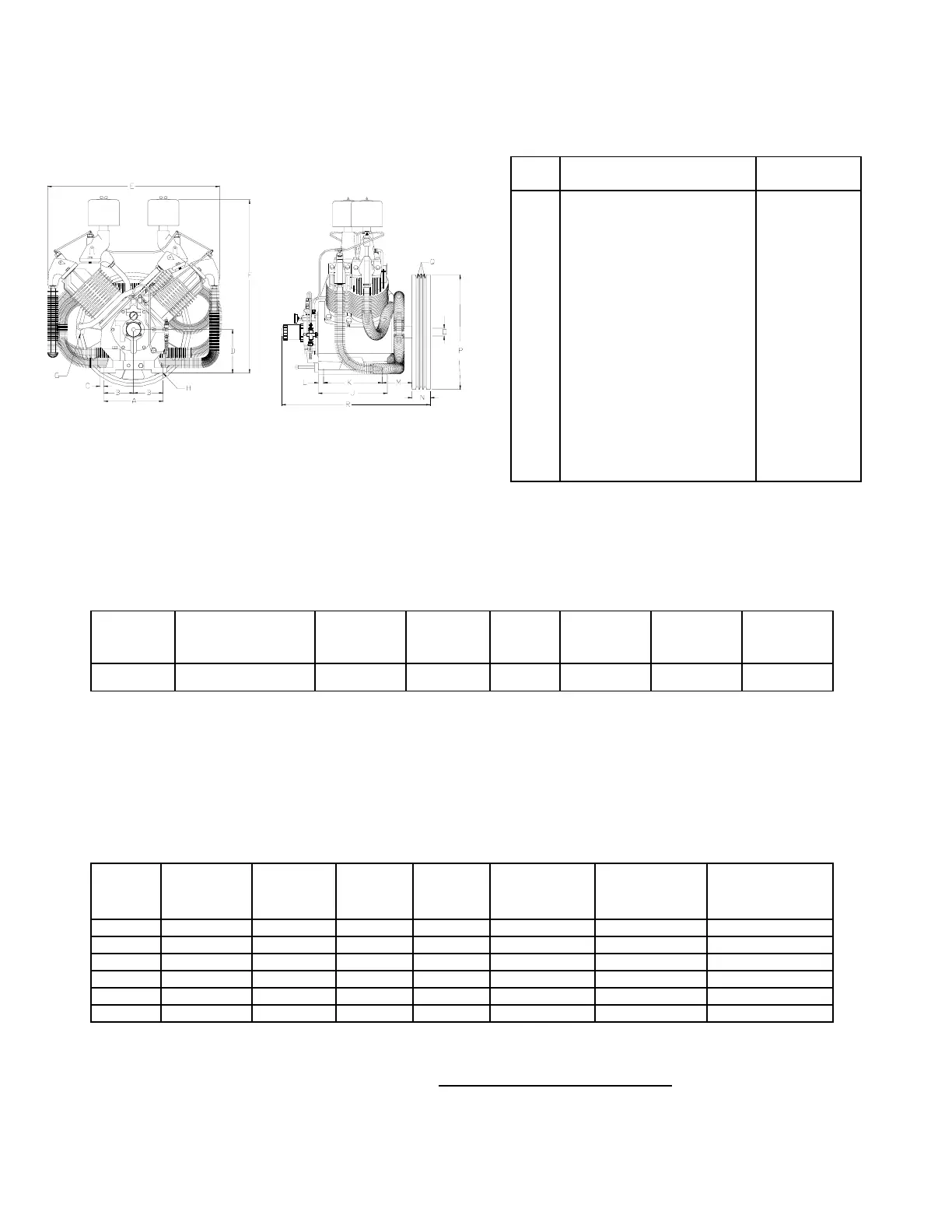

SPECIFICATIONS

MODEL BORE & STROKE

(INCH)

NO. of

CYLINDERS

OIL

CAPACITY

(QTS)

WEIGHT

(LBS)

MAXIMUM

PRESSURE

(PSIG)

CU

FT./REV.

MIN./MAX.

RPM.

PL70A 6-1/4" & 3-1/4" x 4" 4 6-1/3 450 250 .142 425/1000

Standard units are set up for 175 PSIG operation. High pressure units are set for the higher 250 PSIG range and

come with the special tanks, pressure switches, pressure relief valves, pulleys and pilot valves. To determine the

pressure setting of a particular compressor check the pressure setting decal located on the air tank.

Note that 175 PSIG units cannot be converted to safely operate at pressures above 200 PSIG unless all the above

mentioned components including the air tank are replaced with 250 PSIG rated items. Refer to parts list for

applicable part numbers.

PERFORMANCE

PUMP

OUTPUT

PRESS.

PSIG

MOTOR

H.P.

PUMP

RPM

DISPL.

CFM

COOLING

AIR FLOW

CFM

HEAT

REJECTION

BTU/HR

APPROX.

PULLEY O.D.,

INCHES

PL70A 175 20 655 93.0 2195 44

700 8.35

PL70A 175 25 770 109.4 2580 55

970 9.75

PL70A 175 30 890 127.8 2980 67

160 11.35

PL70A 250 20 545 77.4 1825 44

700 6.75

PL70A 250 25 660 93.7 2195 55

970 8.35

PL70A 250 30 770 109.4 2580 67

160 9.75

All data is based on 1725 RPM electric motors as a power source.

Pulley Dia. (approx.) = Compressor RPM x Flywheel Dia.

Motor or Engine RPM

C-331-

(Ref. Drawing)

Loading...

Loading...