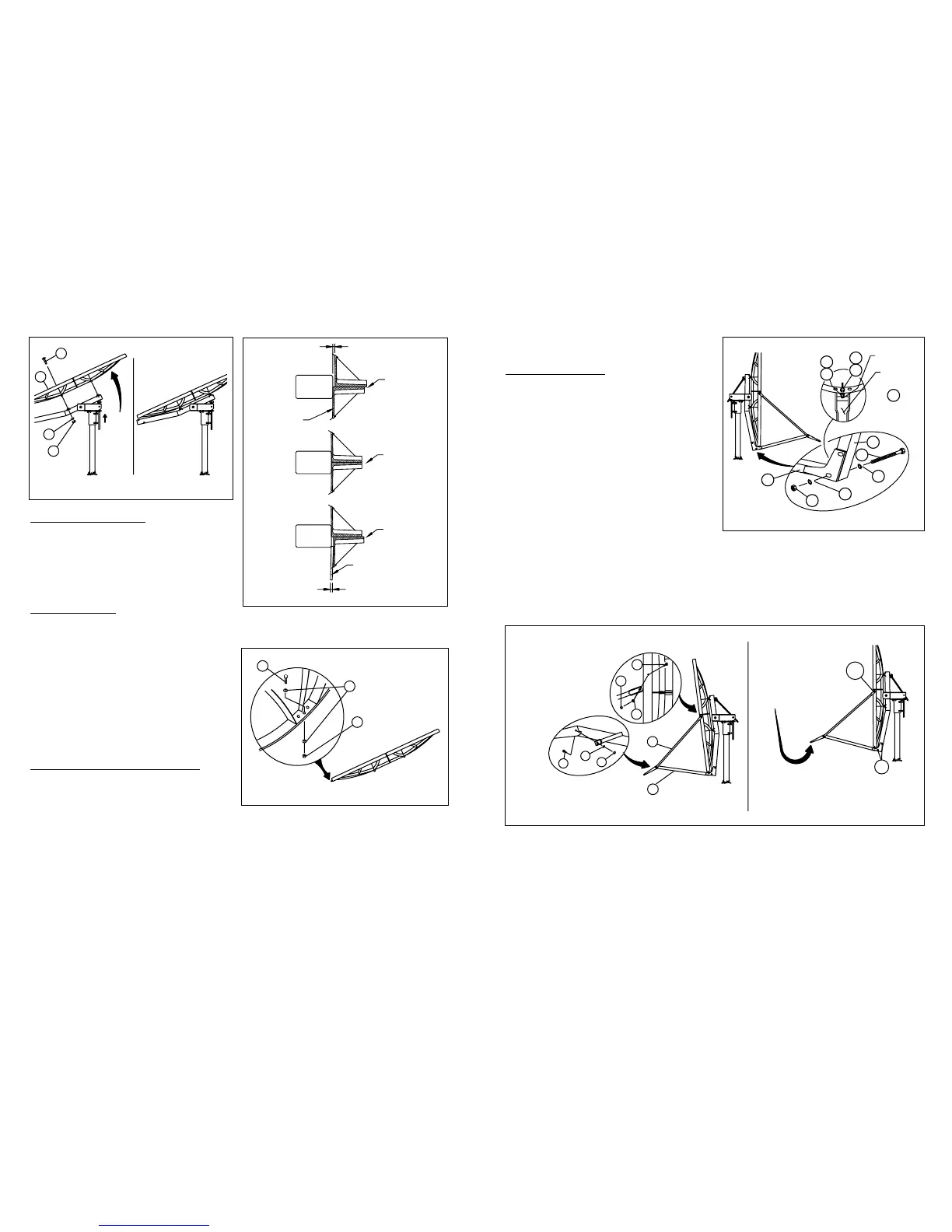

ANTENNA INSTALLATION

6 - Insert four ⁵⁄₈”x 5¹⁄₂” round head square neck bolts

(2) into reflector assembly (5) and affix on to back-

frame. Reflector section marked “TOP” must be located

at the top end of backframe. Make sure round head

square neck bolts are seated correctly before securing

reflector to backframe. Secure reflector to backframe

with ⁵⁄₈” lock washers and hex nuts. Leave these

bolts loose. Reference Figure 1.4.

SEAM ALIGNMENT

7 - Lower reflector to vertical position by running

down two elevation nuts (14).

8 - Check the horizontal seam match as shown in

Figure 1.5. If alignment is required, begin at the outer

rim by pushing or pulling on the bottom reflector rim,

while another tightens their seam bolts at this loca-

tion. Continue this process, working toward the cen-

ter, and alternating from one side to the other.

9 - After all seam bolts are tightened, torque bolts,

using the same sequences as above, to 35 ft-lbs. Now

tighten and torque (4) reflector mounting bolts to 35 ft-lbs.

NOTE: Certain models reuqire additional alignment

instructions. Refer to supplement for detailed instruc-

tions.

FEED SUPPORT TUBE INSTALLATION

10 - Install ¹⁄₄”x 1 ¹⁄₂” hex bolt with flat wahser (46 &

7) into bottom hole in reflector and secure with ¹⁄₄” flat

washer and hex nut (7 & 6). Reference Figure 1.6

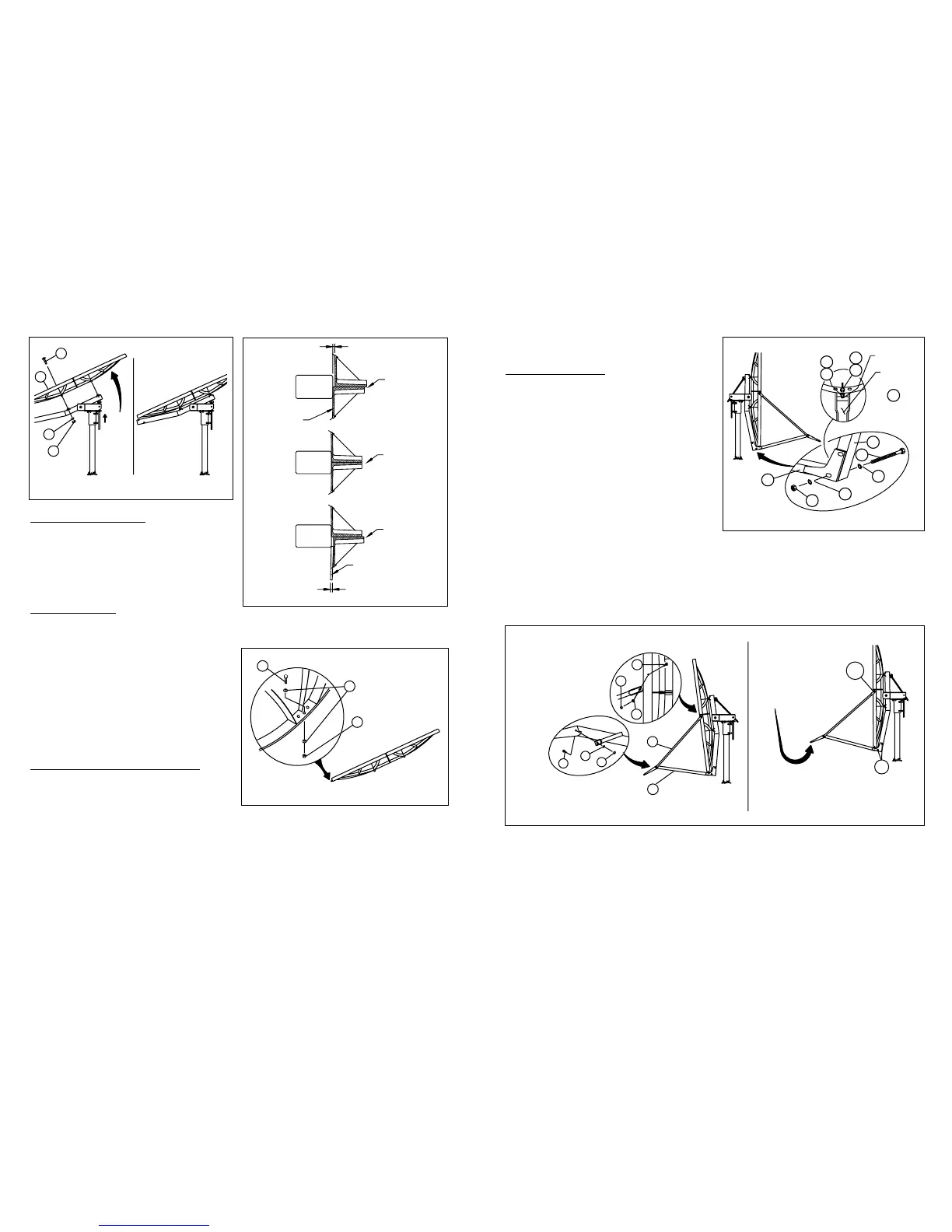

11 - Install feed support tube (10) onto backframe

and secure with two ¹⁄₂”x 5¹⁄₂” hex bolts, four external

tooth lock washers and hex nuts (12, 11 & 4).

Reference Figure 1.7.

IMPORTANT: ¹⁄₄”x 1¹⁄₂” hex gage bolt (Item 46) in

bottom of reflector fits into hole on top of support

tube end (Item 10). Reference Figure 1.7.

NOTE: ¹⁄₂” external tooth washers (11) must be

assembled on bolts, with one under head of bolts

and one under hex nuts (4), refer to Figure 1.7.

Lea

ve these bolts loose.

12 - Install left and right side struts onto reflector as

shown in Figure 1.8.

Attach long formed end of side struts (27) to

reflector rim by inserting ¹⁄₄”x ³⁄₄” hex head bolt (28)

through inside of reflector rim and secure snug, but

free to pivot with ¹⁄₄” lock washer and hex nut (6 & 8).

Attach short formed end of side struts (27) to feed

support tube with ¹⁄₄”x ³⁄₄” hex bolt, lock wahesr and

hex nut (28, 8 & 6). Tighten and torque hardware

securing side struts to feed support tube only to 6 Ft-

lbs (8 N-m).

13 - Without using excessive pressure, lift feed

support tube vertically just enough to relieve load off

side struts and bottom rim gage bolt (Item 46). While

another person tightens and torque’s ¹⁄₂” hex head

bolts (*) securing feed supprot tube to backframe to

35 Ft-lbs (47 N-m). Tighten and torque ¹⁄₄” hex head

bolts (**) securing side struts to reflector to 4 Ft-lbs

(5.4 N-m). Reference Figure 1.9.

14 - To install ODU or Feeds, see instructions

supplied with these kits.

Loading...

Loading...