27

TroubleshootingProduct Manual - Perma-Cyl

®

w/ FlexFill™ Piping Option

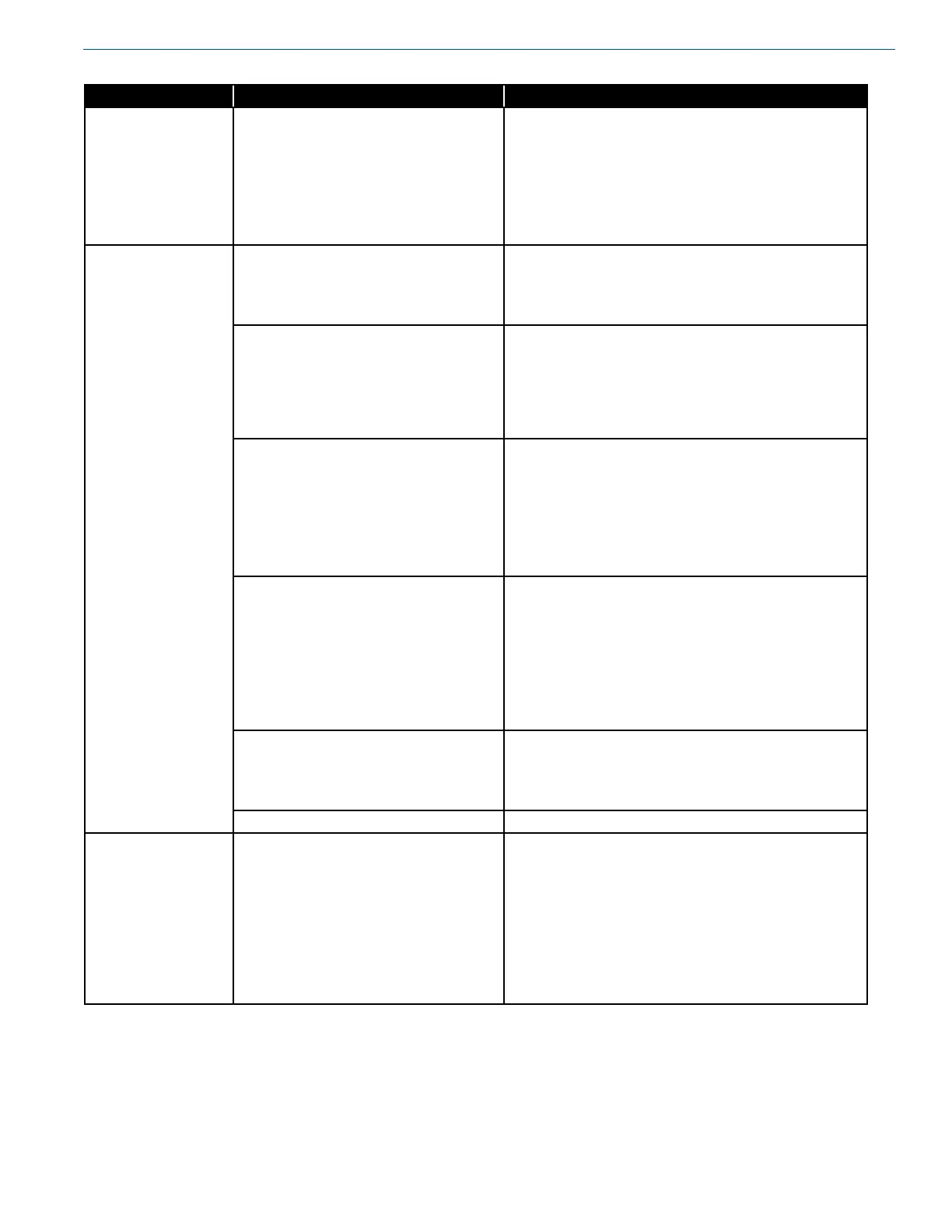

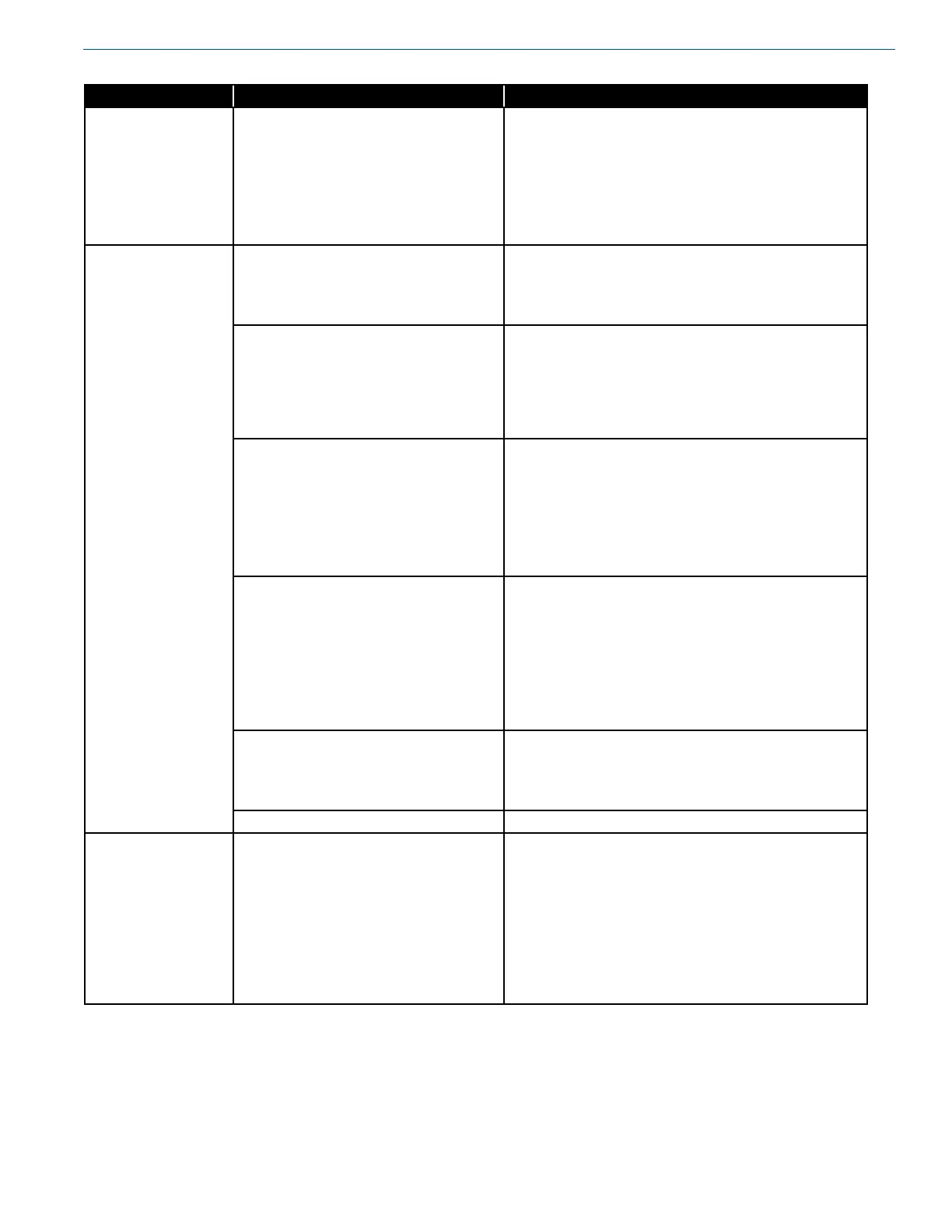

Trouble Probable Cause Remedy

Gas supply to gas-

use equipment is too

cold. (continued)

Gas withdrawal rate from Perma-Cyl tank

exceeds the capacity of tank’s ambient

vaporizer.

1. Reduce gas withdrawal rate to within specied

parameters.

2. Install freestanding ambient vaporizer on gas

supply line in warm location or install in-line heated

vaporizer on gas supply circuit.

3. Install larger tank with greater withdrawal rate

capacity.

Routinely high tank

pressure.

Normal when little or no gas has been

used for several days.

1. None - Routine use of gas will automatically

reduce the tank pressure.

2. Gas usage must exceed NER of tank, if not,

contact gas supplier for different tank model.

Economizer function on regulator is

malfunctioning.

1. If tank is in a mixer application and the usage is

low, consider drawing gas off the vent line, as

the economizer will not work completely in non-

consistent draws.

2. Call gas service technician to clean, repair, or

replace regulator.

Tank is over-lled 1. If tank is lled to or beyond proper ll level,

pressure builds very rapidly and relief valve may

open.

2. Use gas or liquid as soon as possible to reduce

tank contents.

3. Vent tank until no liquid is coming out the vent

valve.

Pressure building function on

regulator is set too high or regulator is

malfunctioning.

1. Reduce pressure setting by turning adjustment

knob counter-clockwise to the desired pressure

setting and continuing normal gas use until

pressure drops.

2. Close PB isolation valve and carefully observe

pressure to ensure tank pressure does not drop

too low during use.

3. Call gas service technician to adjust PB regulator.

Weak or failed vacuum. 1. Observe if condensation and / or frost are present

even during periods of non-use as possible sign of

vacuum problem.

2. Call gas service technician.

Unknown. 1. Call gas service technician.

Hissing sounds or

evidence of gas

leaking near tank,

gas lines, or gas-use

equipment.

Normal for short periods of time from

some regulators and relief valves.

1. Evacuate and ventilate room or area, if necessary.

2. If possible, observe leak. If leak is not large, does

not last long, does not occur frequently and is in

well-ventilated area, no action may be needed.

If in doubt, call appropriate equipment service

technician.

3. If above combined conditions do not exist, call

equipment service technician and observe “Safety”

precautions.

Loading...

Loading...