28

Troubleshooting Product Manual - Perma-Cyl

®

w/ FlexFill™ Piping Option

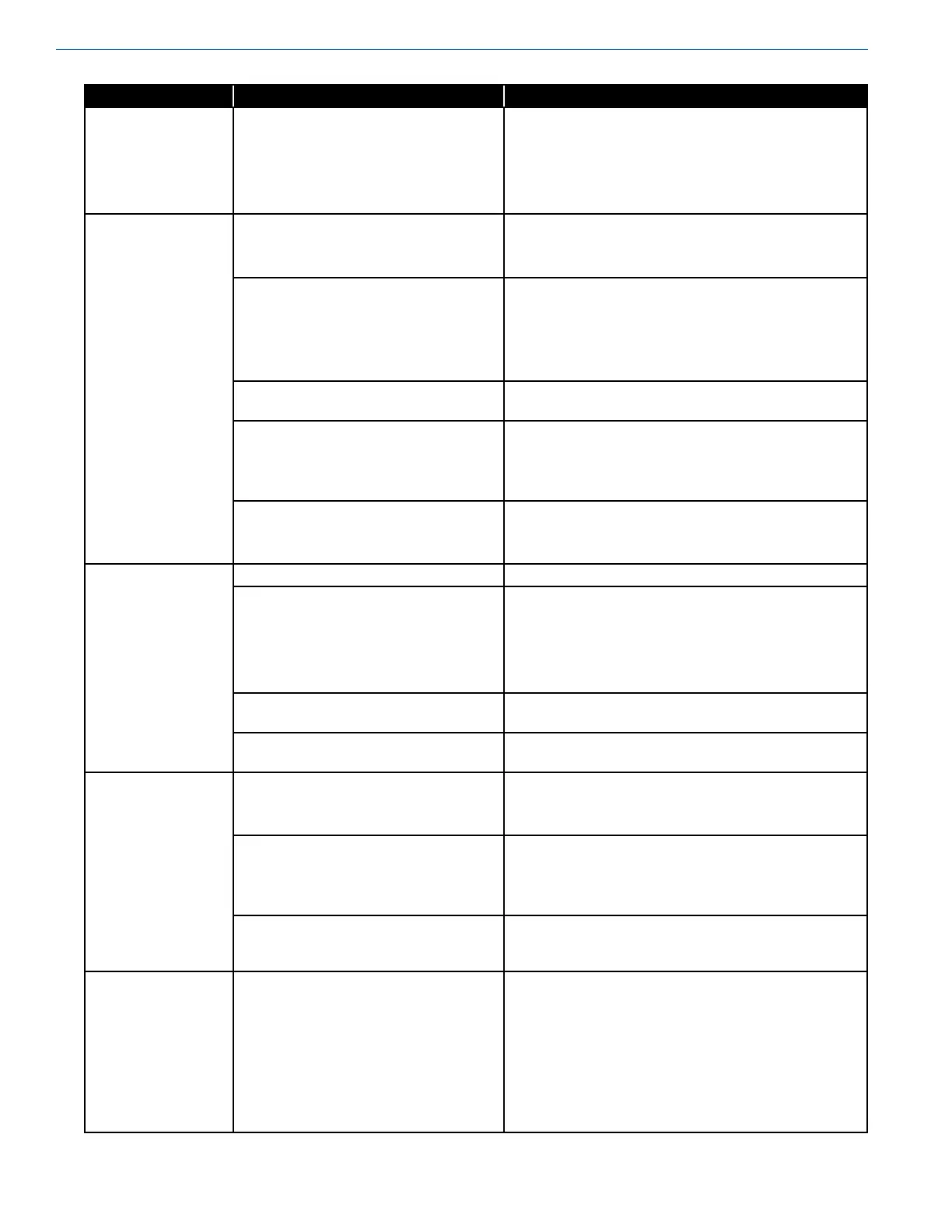

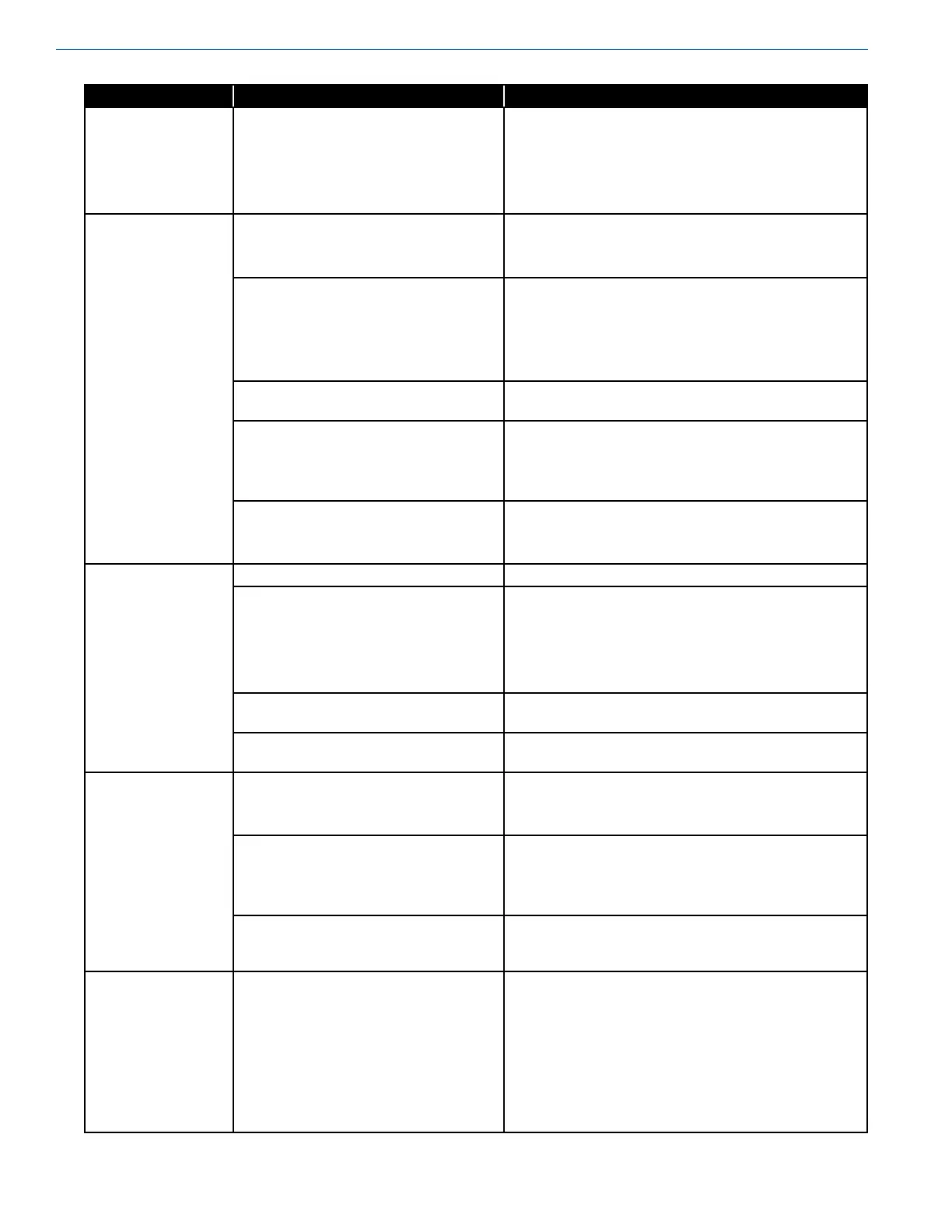

Trouble Probable Cause Remedy

Hissing sounds or

evidence of gas

leaking near tank,

gas lines, or gas-

use equipment.

(continued)

Large leaks, leaks from elsewhere in

the system, sustained leaks, or frequent

leaks (not normal).

1. Evacuate all personnel from affected areas.

Ventilate room / area.

2. If possible, locate the leak and repair it or call gas

service or gas-use equipment service technician.

High gas usage. Unrecognized increase in actual gas use. 1. None for Perma-Cyl tank or gas supplier

2. Gas user to determine reason for increase in gas

use.

Leak in gas supply line or network or in

gas-use equipment or tank plumbing, e.g.

relief valve.

1. Evacuate and ventilate room, if necessary.

2. If possible, locate and repair leak or call gas-use

equipment service agent.

3. User to check tank for frost / leaks before

operations.

Tank pressure routinely too high and

venting.

1. See troubleshooting section on routinely high tank

pressure.

High ash or vaporization losses in liquid

use application due to high pressure /

temperature liquid in tank.

1. Vent tank to approximately 25 psi. Follow safety

procedures.

2. In future only rell the Perma-Cyl tank with low-

pressure cryogenic product.

Error in gas delivery or supplier invoice. 1. Check gas usage history / pattern against supplier

invoices.

2. Call gas supplier, if necessary.

Perma-Cyl tank

cannot be lled.

Perma-Cyl tank is full. 1. None

Fill line is blocked or inoperative. 1. Check for obstructions in the ll line. Clear if

necessary.

2. Gently tap on check valve to assure proper

operation.

3. Ensure top & bottom ll valves are open.

4. Call gas service technician.

Orca

™

MicroBulk Delivery System is not

functioning properly.

1. Refer to Orca system Troubleshooting.

Transfer hose is obstructed, e.g. hose is

bent excessively, crimped or plugged.

1. Clean obstruction, inspect hose for damage, and, if

everything is satisfactory, continue the lling.

Perma-Cyl tank does

not initiate automatic

ll shut off properly.

Fill line piping created too much pressure

drop.

1. Ensure ll line is piped with 3/4” nominal copper (or

equivalent) with minimal 90° bends.

2. Re-route ll piping.

Improper ll procedure. 1. Review Orca system/Perma-Cyl tank lling

procedure.

2. Ensure that all vent and use valves of the tank are

closed.

Only works with Chart Orca MicroBulk

delivery vehicle. For other type trucks use

full trycock.

N/A

Liquid withdrawal

contains high level

of gas.

Saturated liquid pressure in Perma-Cyl

tank is too high. (Temperature or energy

level of contents is too high due to

excess pressure.)

1. Ensure PB shut-off valve is closed.

2. Open vent valve to allow excess pressure to vent

until desired pressure is obtained. Follow “Safety”

guidelines and procedures for venting.

3. Install secondary lower pressure relief valve to

reduce saturated pressure of liquid in the future.

4. In future only rell the Perma-Cyl tank with low-

pressure cryogenic product.

Loading...

Loading...