9

InstallationProduct Manual - CryoDoser FleX

™

LN

2

Dosing System

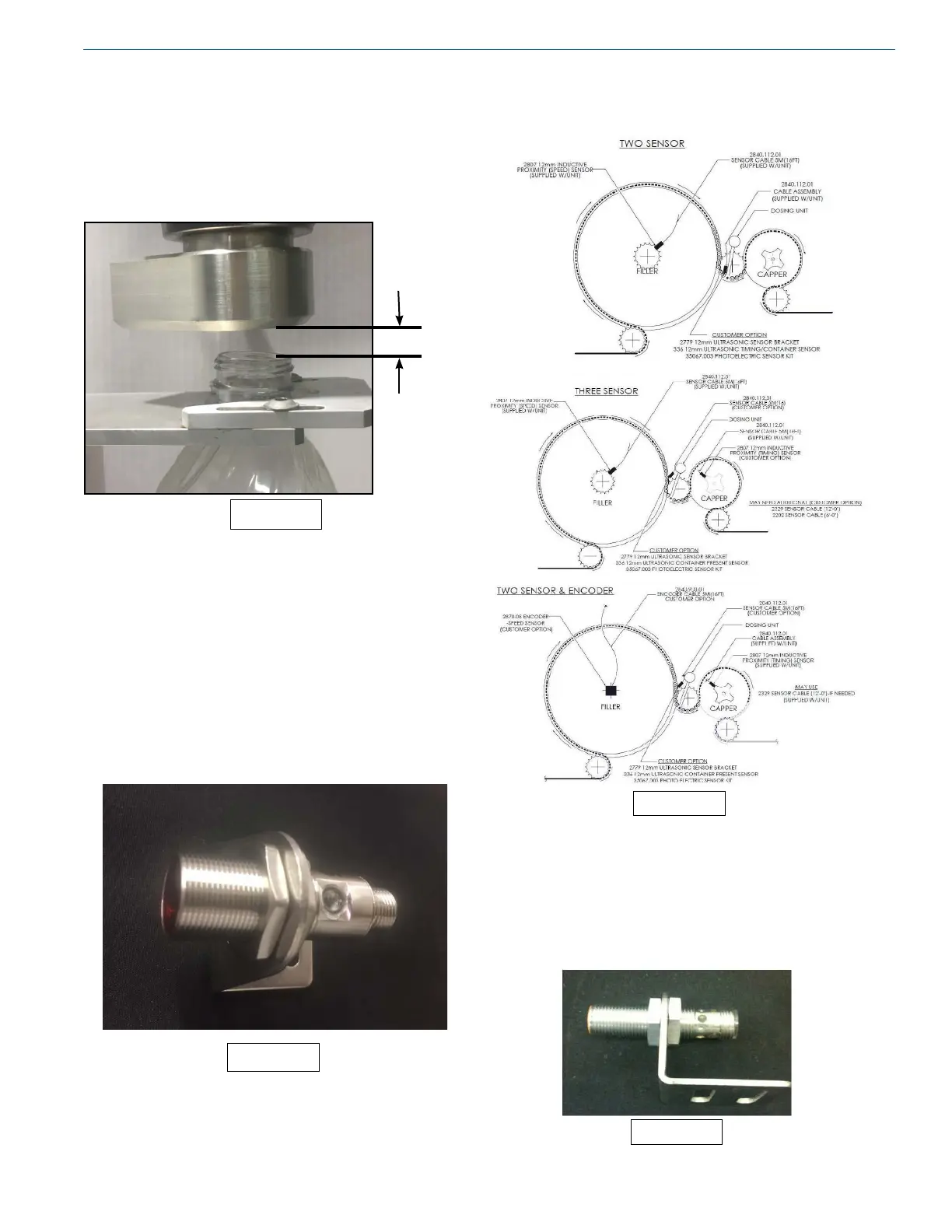

Positioning the Dosing Head

The dosing head should be directly over the container

opening. The dosing head is typically installed 1/2” - 3/4”

above the container opening. The CryoDoser FleX unit

must be manually adjusted to accommodate different sized

containers running on the same production line.

Installing the Container Detect Sensor

The container detect sensor must be a PNP type sensor and

is used to detect if containers are present on the line. Chart

provides a container detect sensor with the CryoDoser FleX

system (Image 13). Ideal sensor placement is about four

to six pockets from the dosing head. If the sensor does not

detect a container for the user dened number of seconds,

the CryoDoser FleX unit will stop dosing. See the Inputs/

Outputs and Container Sensor sections for additional

information.

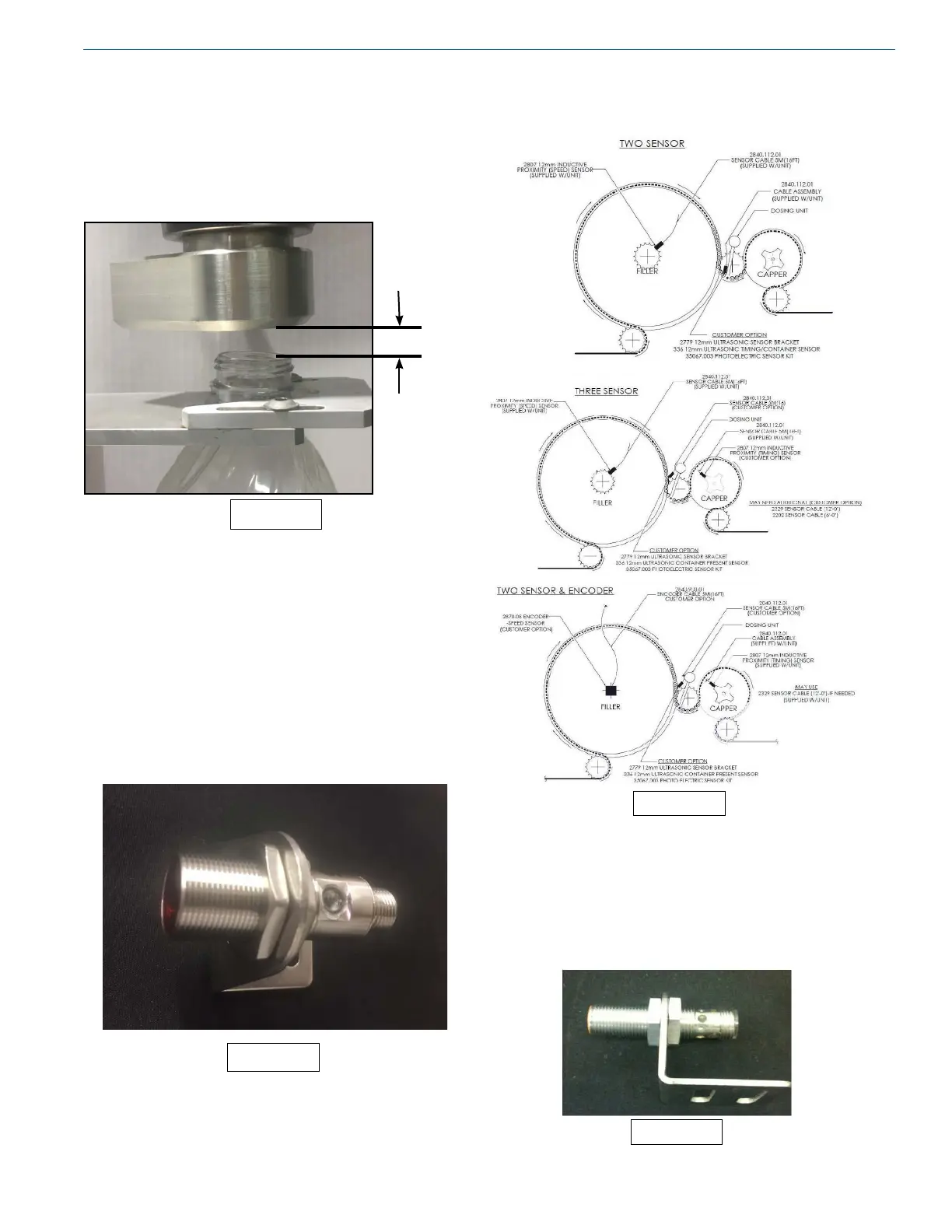

The diagram below shows three different ways of positioning

the sensor.

Installing the Timing Sensor

The timing sensor is installed to identify container location

and must be installed for the CryoDoser FleX system to

operate properly. Chart provides a PNP 12mm inductive

proximity sensor with the CryoDoser FleX system. Ideal

sensor placement must provide a one-to-one signal.

Image 15

Image 12

0.75in. (19mm)

Image 13

Image 14

Loading...

Loading...