13

Product Manual - CryoDoser FleX

™

LN

2

Dosing System

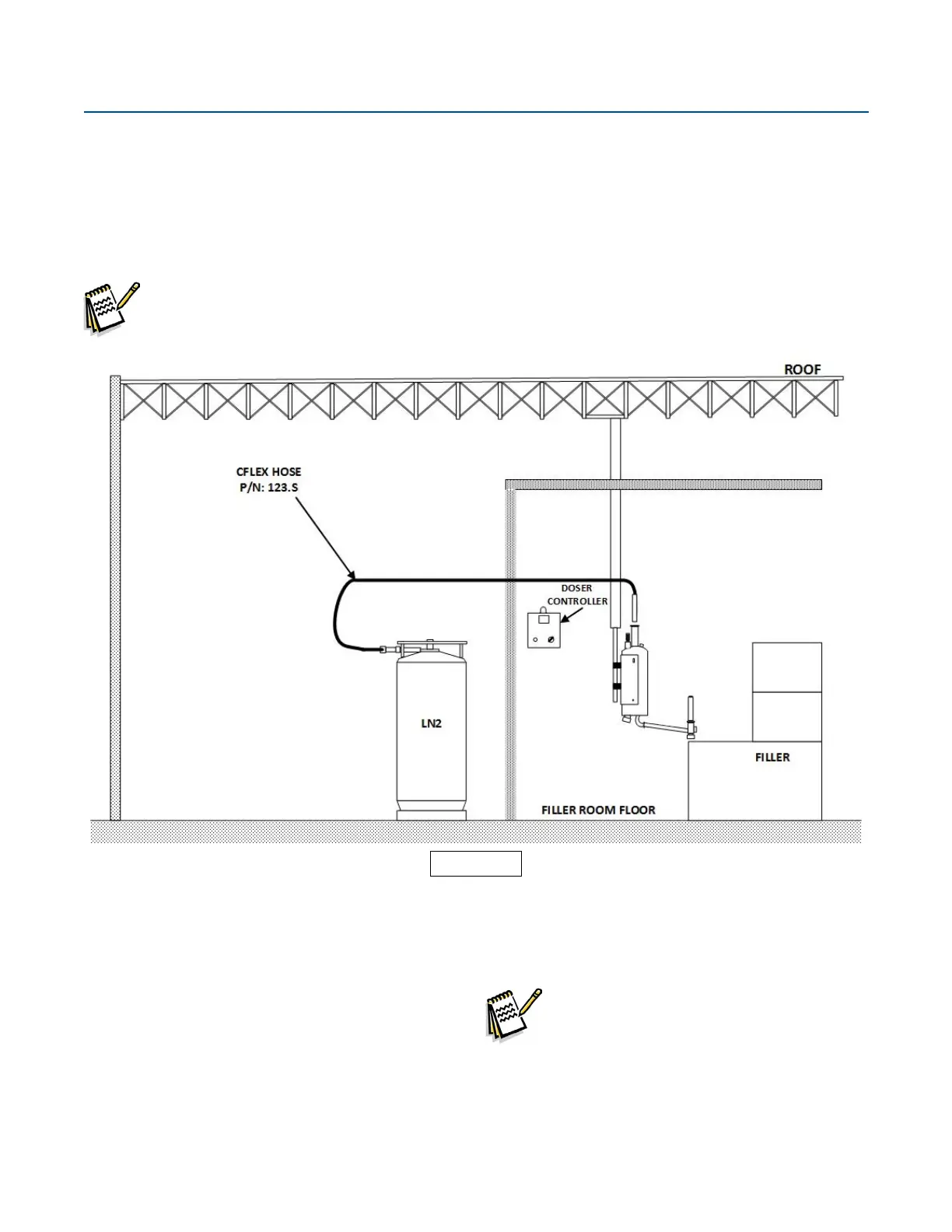

The CryoDoser FleX system can be fed by either a portable

Dura-Cyl

®

Liquid Cylinder or a bulk tank (house fed) liquid

nitrogen system.

Dura-Cyl

®

Liquid Cylinder Fed

System

Note: LN

2

is -320°F (-196°C). Any water and/

or moisture can cause ice which will affect

the performance of the CryoDoser FleX

system. Providing a positive pressure

Daily Operating Procedures

Dura-Cyl Cylinder Change Out Procedure

The Dura-Cyl cylinder will need to be changed out from

time to time. The operator should visually check the gauges

on the Dura-Cyl cylinder to monitor the internal liquid

level. When the gauges read low levels, it must be swapped

with a full Dura-Cyl cylinder. Chart recommends a cylinder

pressure of 60 psi and above.

1. Close the liquid valve (clockwise direction) on the

Dura-Cyl cylinder.

2. Disconnect the C-Flex hose from the Dura-Cyl cylinder

using a 7/8” open end wrench or adjustable crescent

wrench.

3. Connect the C-Flex hose to the liquid outlet on the full

Dura-Cyl cylinder using a 7/8” open end wrench or

adjustable crescent wrench.

Note: The CryoDoser FleX unit will continue to

dose properly until the liquid level inside

the CryoDoser FleX unit runs low. This

feature gives the operator a reasonable

window in which to change out the

Dura-Cyl cylinder without disrupting the

production operation.

of GN

2

(also known as purging) to the

CryoDoser FleX unit before introducing

LN

2

into the body will eliminate many

performance interruptions.

Image 22

Loading...

Loading...