18

Service and Maintenance Product Manual - CryoDoser FleX

™

LN

2

Dosing System

Troubleshooting

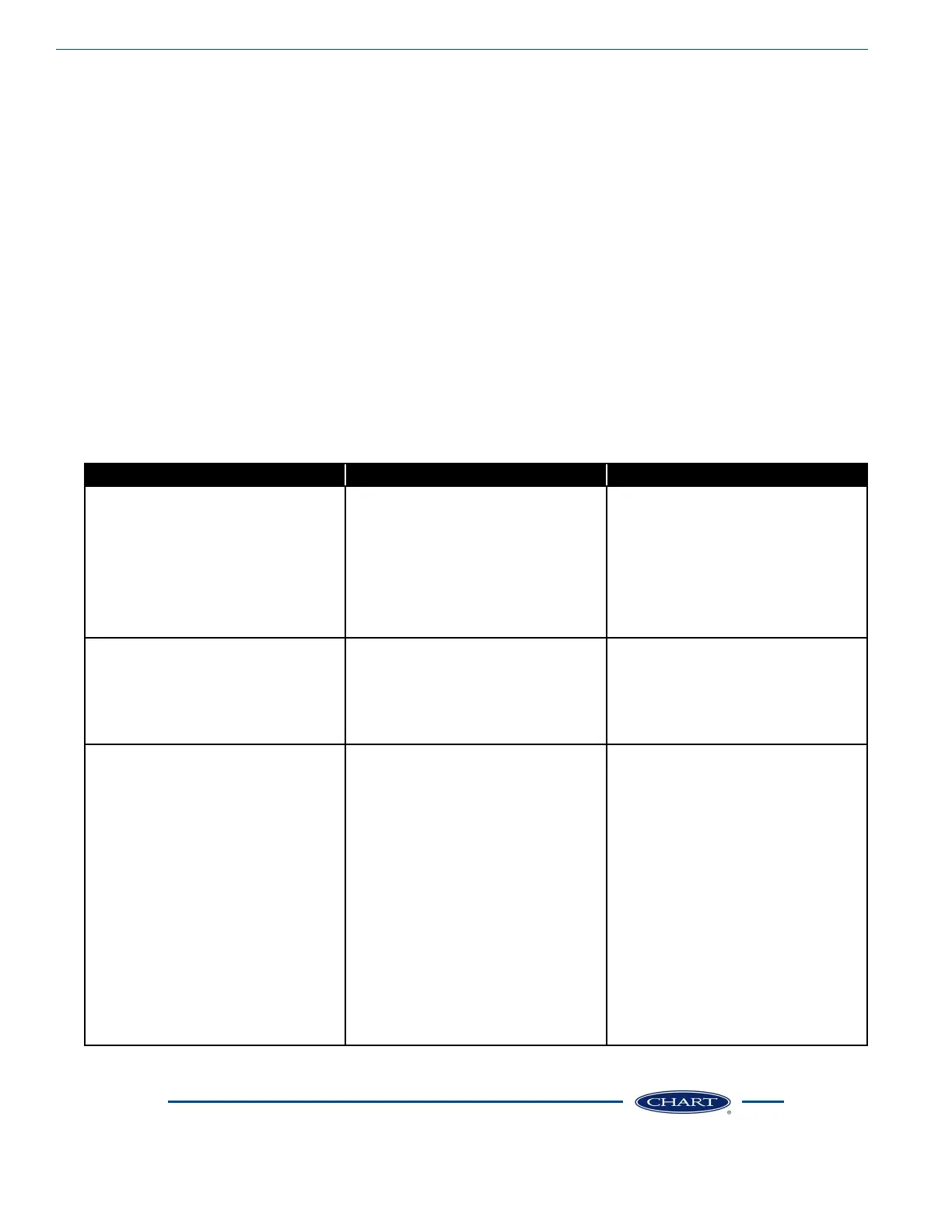

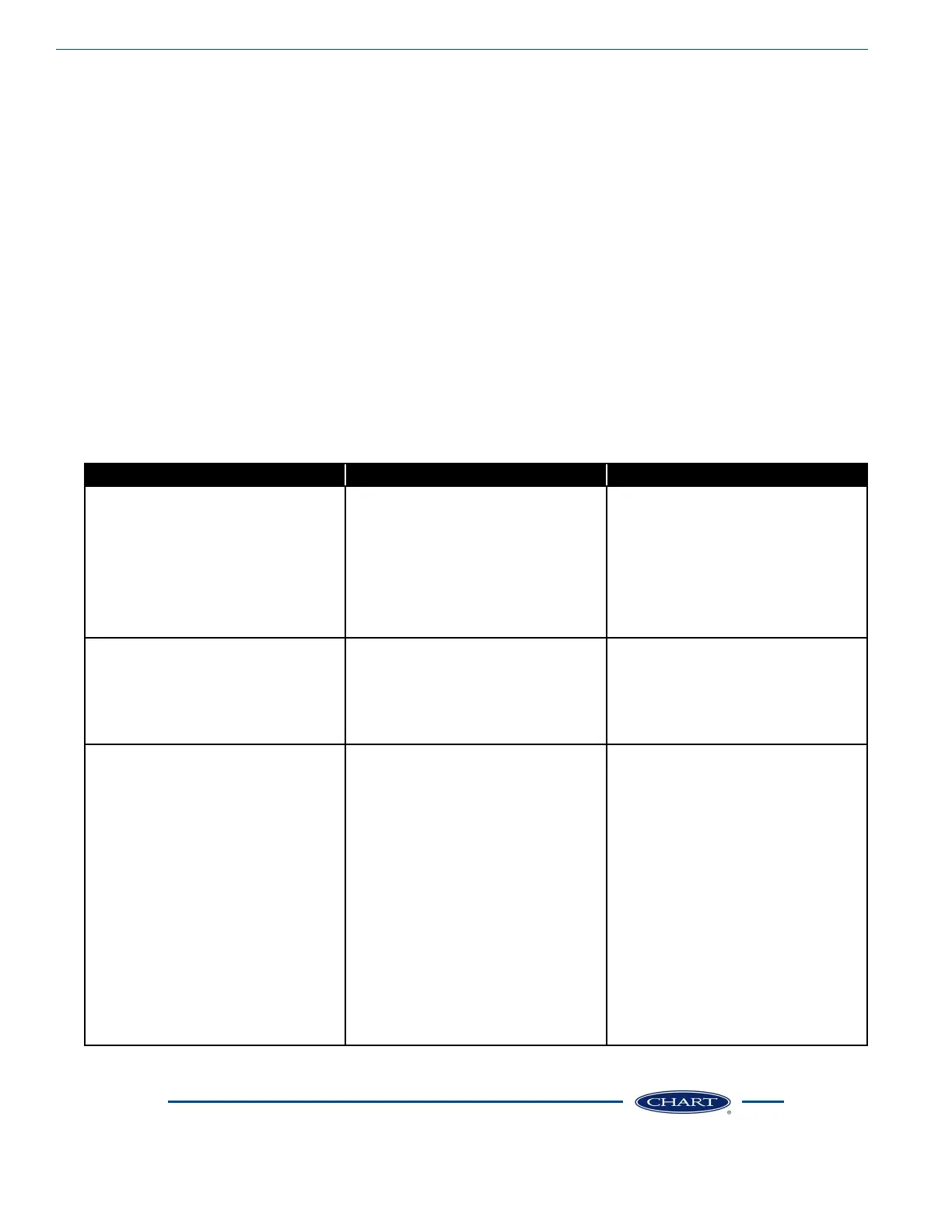

Refer to the table below for troubleshooting procedures. The table is arranged in a Symptom/Possible Cause/Solution format.

Note that possible causes for specic symptoms are listed in descending order of signicance. That is, check out the rst

cause listed before proceeding to the next. If you need further assistance please contact Chart’s service team at 1-408-371-

4932.

Symptom Possible Cause Solution

Liquid is coming out of the vent. The LN

2

supply pressure is too high.

Ice has developed inside the unit,

causing the inlet valve to malfunction.

Lower LN

2

supply pressure to 120 psi

(8.3 bar) or lower.

The CryoDoser FleX unit must be

drained of liquid, allowed to warm with a

continuous purge of warm nitrogen gas.

Contact Chart’s service team at 1-408-

371-4932 for a detailed procedure.

Liquid is coming out of the dosing head

even though the valve is closed.

The valve seat is contaminated (ice or

particles).

The CryoDoser FleX unit must be

drained of LN

2

. The dosing valve

assembly must be removed and

cleaned.

Contact Chart’s service team at 1-408-

371-4932 for a detailed procedure.

No liquid from the dosing head. There is insufcient liquid inside the

CryoDoser FleX unit.

The unit is disabled.

The nozzle is frozen shut.

The container detect sensor is not

detecting a container.

Check the level of LN

2

. If the level is

empty or low, open the supply valve.

Pull out the Dose Enable switch to

enable mode (ensure switch is not lit).

Run Insta-Purge to thaw nozzle.

Remove, clean, and re-install the

nozzle (see Nozzle Change Out section

for additional information).

Check sensor connections. Ensure

the sensor is correctly positioned to

detect points (gear tooth or the like).

If necessary, replace sensor, cable or

both.

Purging with Gaseous Nitrogen

The CryoDoser FleX

™

unit must only be purged with

gaseous nitrogen. Chart recommends the CryoDoser FleX

unit be purged when not in use. However, this may not be

practical for all operators. At a minimum, the CryoDoser

FleX unit should be purged after installation and prior to

startup to eliminate any water that may be inside the unit.

The CryoDoser FleX reservoir may also require purging

when there is liquid nitrogen owing out of the vent. The

CryoDoser FleX reservoir must also be purged when the

nozzle becomes frozen shut.

See the Dura-Cyl

®

Liquid Cylinder Fed System and

Bulk Tank (House Fed) System sections for additional

information.

Loading...

Loading...