Use a sponge soaked with soap water or a leakage detector to check the

connectors and access-valves on indoor and outdoor units. Keep testing for no

less than 3 minutes at each position. When the leakage detection is completed,

do wash away the residual soap water. (Notes: In summer, leakage detection

should be done under stop state. In winter, it should be done under heating

mode). )

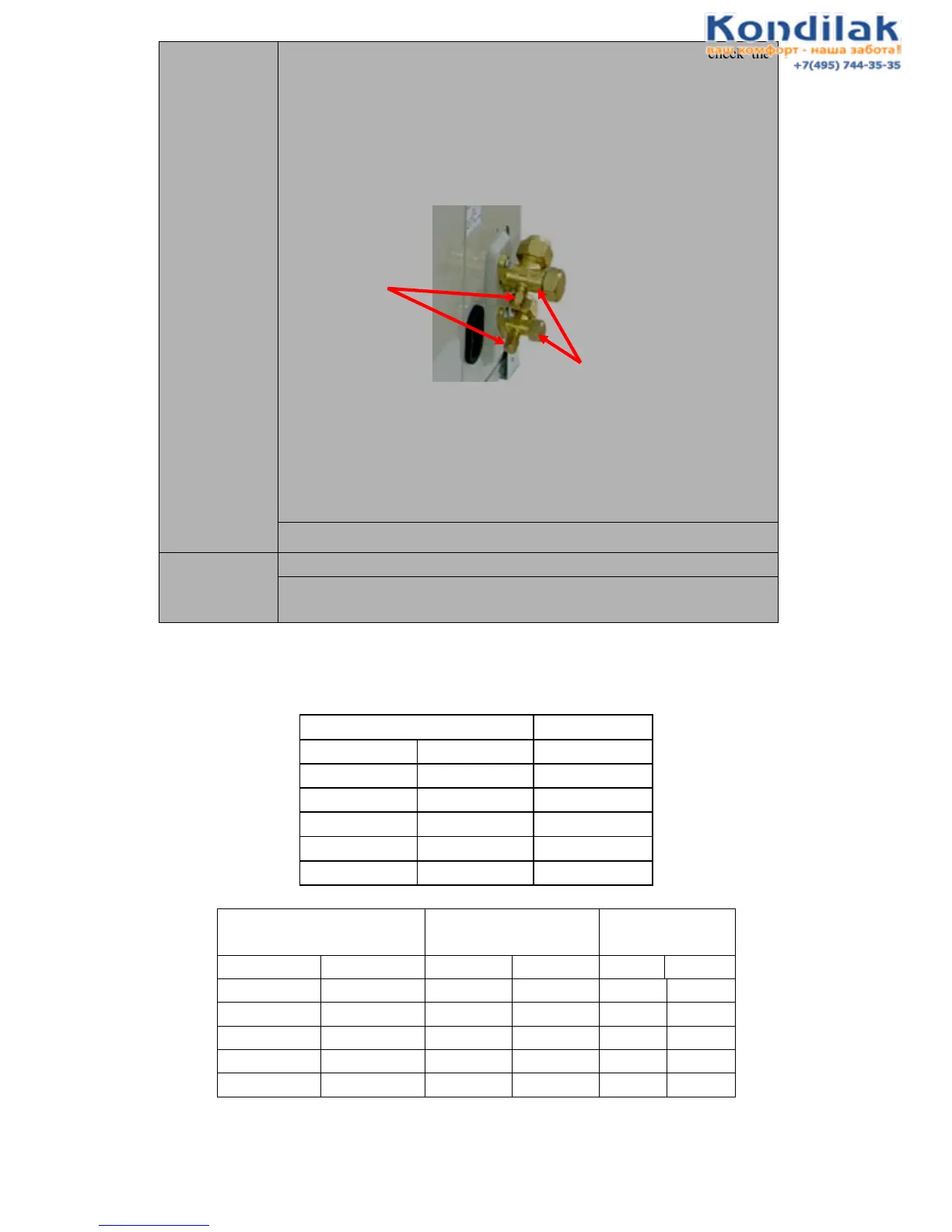

Position Most Likely to Leak

Besides four connectors connecting outdoor pipes, nuts at high-pressure /

low-pressure valve core and filling portal are most likely to leak but often

neglected. Therefore, when installing the machine, make sure to fully open the

valve core to dead position and tighten every nut and check for leakage.

Use pipe bender when bend the pipe with 90°. To avoid flattening or cracking

the pipe without pipe bender, do bend it with a radius as large as possible.

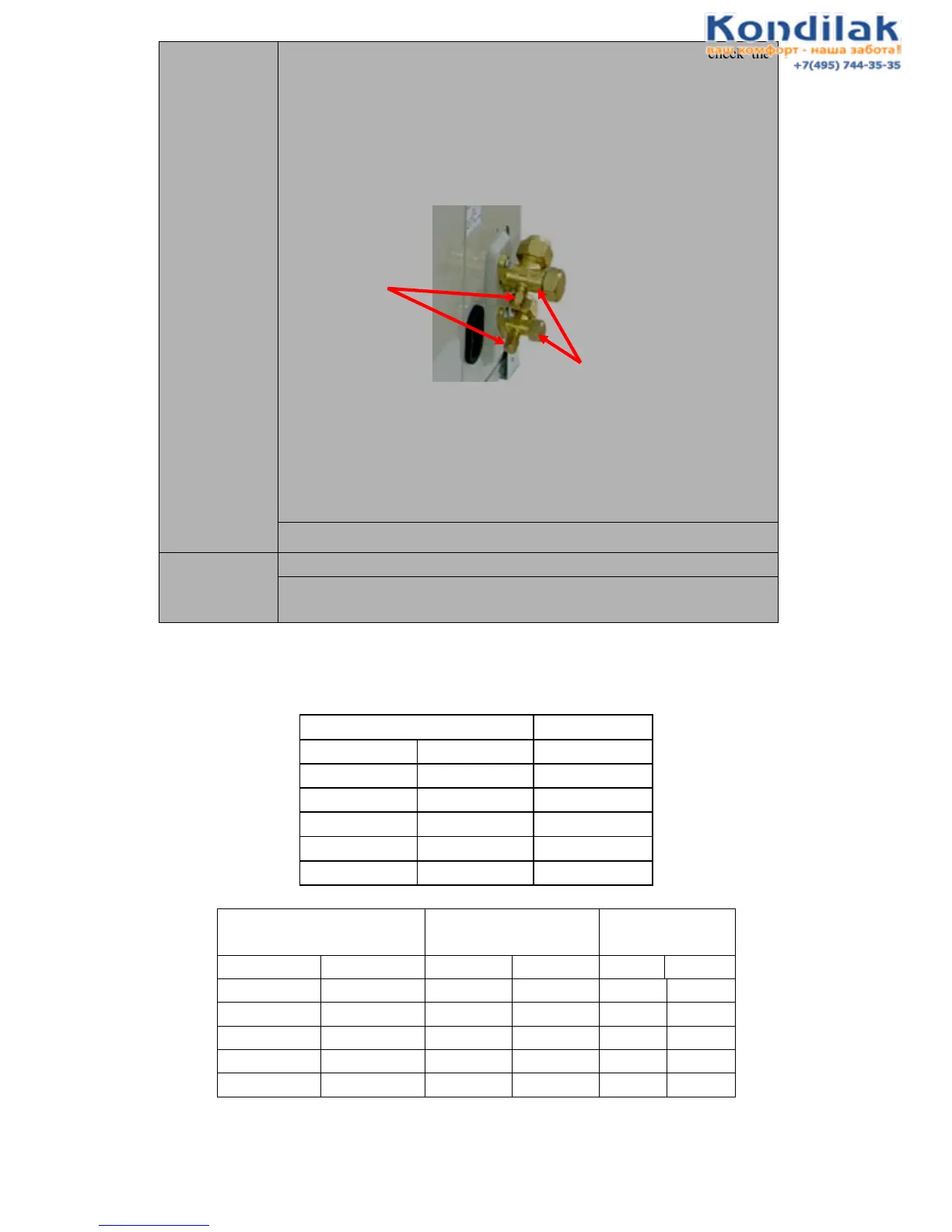

Loading...

Loading...