Maintenance Model 108 FLEX-AUGER® Feed Delivery System

44

MA1714C

The FLEX-AUGER

®

Feed Delivery System requires minimum maintenance. However, a routine periodic

inspection of the equipment will prevent unnecessary problems.

Maintenance should be done by a qualified technician.

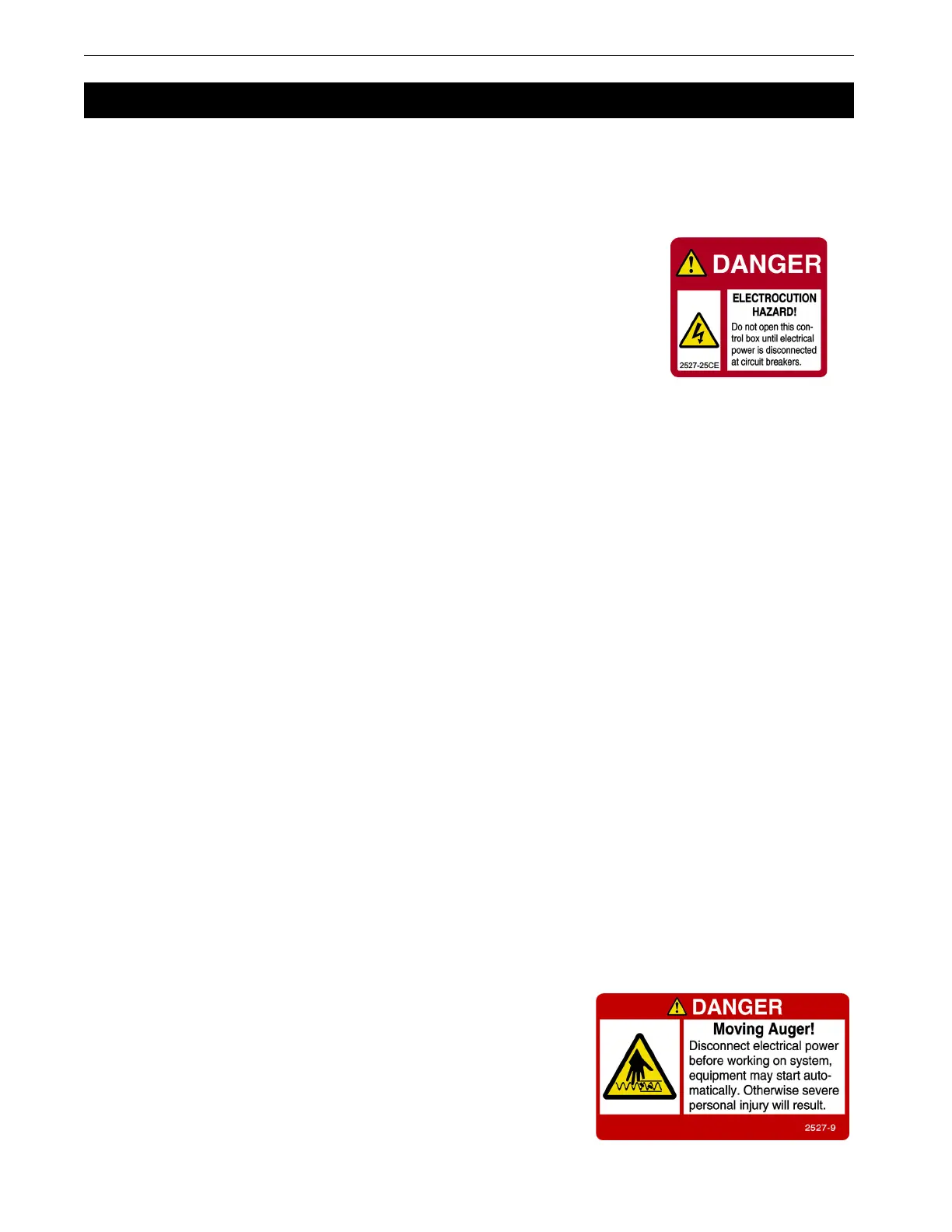

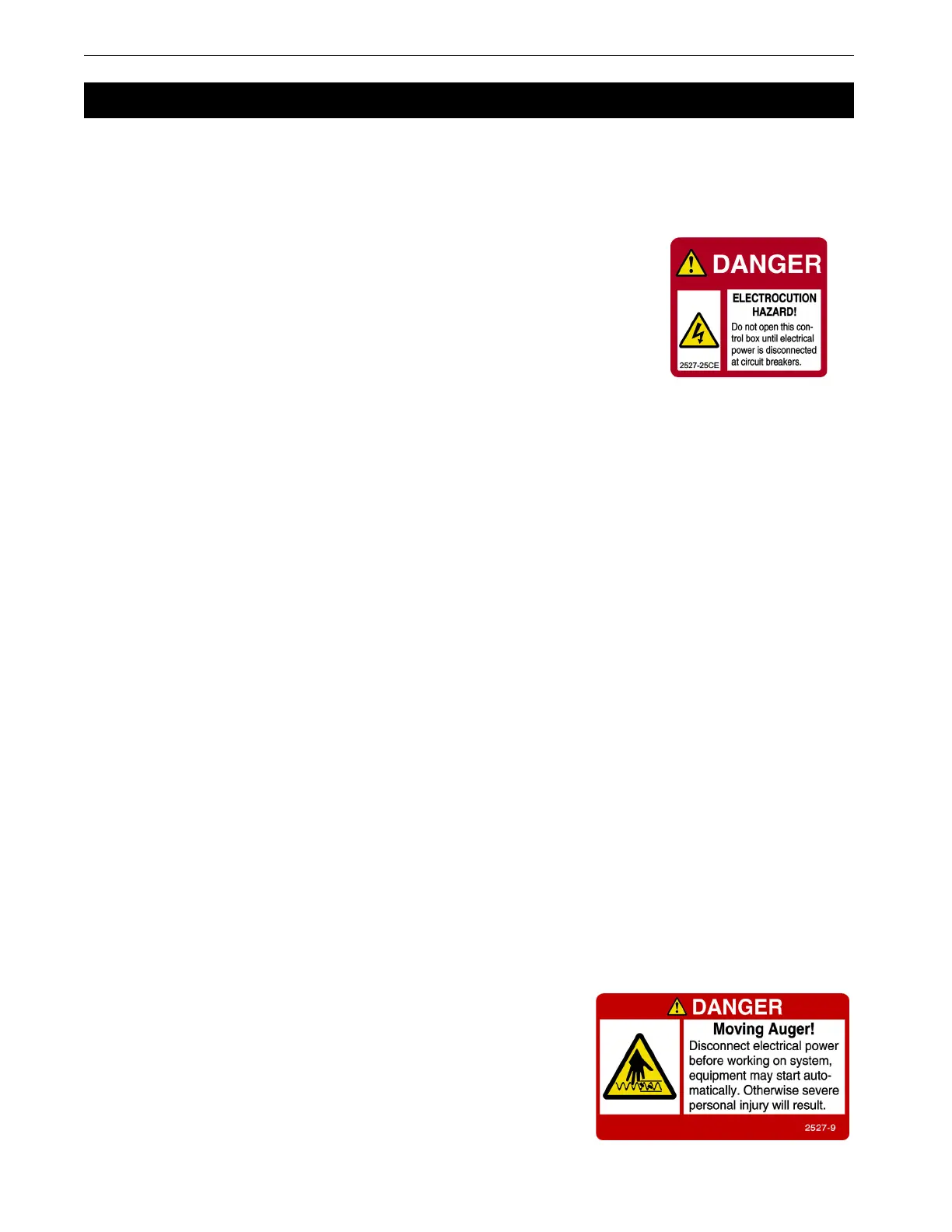

ALWAYS DISCONNECT POWER TO THE SYSTEM WHEN SERVICING

OR MAINTAINING THE EQUIPMENT. FAILURE TO DISCONNECT

POWER MAY CAUSE INJURY OR DEATH.

Oil Recommendation

Use: Mobil Glycoil 30, Shell-Tivela 220, Texaco-Synoil, SG-XP220, Esso-

S220, Telesia Oil 150, BP-Energol SG -XP 220 Synthetic Oil.

1.Periodically check and tighten the delivery system hardware.

2.Grease boot bearings on grease fittings regularly, using an automotive or

industrial type grease.

3.Keep the FLEX-AUGER

®

tubes level. Adjust if necessary. Wear increases at the points where tubes sag.

4.Replace the Plastic Shipping Plug in the power unit gear head with the Vented Plug during installation of the

Power Unit.

5.Check the oil level in the gear heads at installation and every 6 months. The Pipe Plug, on the side of the gear

head, indicates proper oil level. Add SAE 40W oil when necessary.

The oil in the gear heads should be replaced every 12 months with new SAE 40W oil.

A. Remove the bottom Pipe Plug to drain the oil. Discard used oil in accordance with local and national

codes.

B. Wipe any debris off the magnet on the bottom Pipe Plug and reinstall. Remove the side Pipe Plug and

(top) Vent Plug.

C. Set the power unit in the horizontal position.

D. 2-Stage Gear Heads(3261-1,3261-2, 3261-5, 3261-6, 3261-7, 3261-8, 3261-10, 3261-11, 3261-13,

3261-16, 3261-17): Add approximately 9 oz. (266 ml) of SAE 40W oil through top hole. This should

be just enough oil to reach the side Pipe Plug.

3-Stage Gear Heads 3261-14, 3261-15, 3261-21, 3261-22): Add approximately 13 oz. (384 ml) of SAE

40W oil through top hole. This should be just enough oil to reach the side Pipe Plug.

E. Install the side Pipe Plug and (top) Vent Plug.

6. If the system is not to be used for an extended period of time, remove all the feed from the auger lines.

Disconnect power to the system to prevent accidentally starting the system.

7. If the system must be disassembled, extreme caution must be used to prevent injury from springing auger.

A. Disconnect power to the entire system.

B. Pull the Anchor and Bearing Assembly and approximately 18” (45 cm) of auger out of the boot.

C. Place a clamp or locking pliers on the auger to prevent it from springing back into the auger tubes.

D. Remove Anchor and Bearing Assembly.

E. Carefully release the clamp securing the auger.

CAUTION: Stand clear...the auger will spring back into the

tubes.

F. Remove the remaining system components in the opposite order

they were installed, according to this manual.

Maintenance

Loading...

Loading...