1

1 Introduction

2 Installation

These instruments are microprocessor based tempera-

ture, process and valve controllers. They can measure,

display or control process variables such as tempera-

ture, pressure, flow and level from a variety of inputs.

Depemding on the model group, three sizes are avail-

able: 1/16 DIN (48 x 48 mm front). 1/8 DIN (48 x 96mm

front) and 1/4 DIN (96 x 96mm front).

The operating voltage is either 100-240V at 50/60 Hz or

24V-48V AC/DC depending on the model purchased.

EEPROM technology protects against data or configu-

ration loss during power outages.

Inputs are user configurable for connection to thermo-

couple and RTD probes, as well as linear process signal

types such as mVDC, VDC or mADC. Output options

include relays, SSR drivers, triacs or linear mV/voltage

modules. These can be used for process control, valve

control, alarms or retransmission of the process vari-

able or setpoint to external devices such as data re-

corders or PLC’s. A Transmitter Power Supply option

module can provide an unregulated 24V DC (22mA)

auxiliary output voltage for external signal transmitters.

Alarm indication is standard on all instruments. Alarms

may be set as process high or low, deviation (active

above or below controller setpoint), band (active both

above and below setpoint), or control loop types. Mod-

els with a heater current input also have high, low or

short circuit heater break alarms based on control load

current. These alarms can be linked to any suitable

output. Alarm status is indicated by LED’s or the alarm

status screen.

Controllers can be programmed for on-off, time pro-

portioning, or current proportioning control implemen-

tations, depending on the output modules fitted, and

feature manual or automatic tuning of the PID param-

eters. A secondary control output is available when ad-

ditional output modules are fitted. Valve Motor Drive

(Three Point Stepping Control) is possible on some

models. Optional analog controller Remote Setpoint

inputs included in the range. Control functions, alarm

settings and other parameters are easily adjusted from

the front keypad or via PC based configuration soft-

ware.

Limit Controllers shut down a process in order to pre-

vent possible damage to equipment or products. They

have latching relay, which cannot be reset until the pro-

cess is in a safe condition. Limit controllers work inde-

pendently of the normal process controller and have

approvals for safety critical applications.

Unpacking

1. Remove the product from its packing. Retain the

packing for future use, in case it is necessary to

transport the instrument to a different site or to re-

turn it to the supplier for repair/testing.

2. The instrument is supplied with a panel gasket and

push fit fixing strap. A single sheet concise manual

is also supplied in one or more languages. Examine

the delivered items for damage or defects. If any are

found, contact your supplier immediately.

Installation

Installation and configuration should be per-

formed only by personnel who are technically

competent and authorized to do so. Local reg-

ulations regarding electrical installation and

safety must be observed.

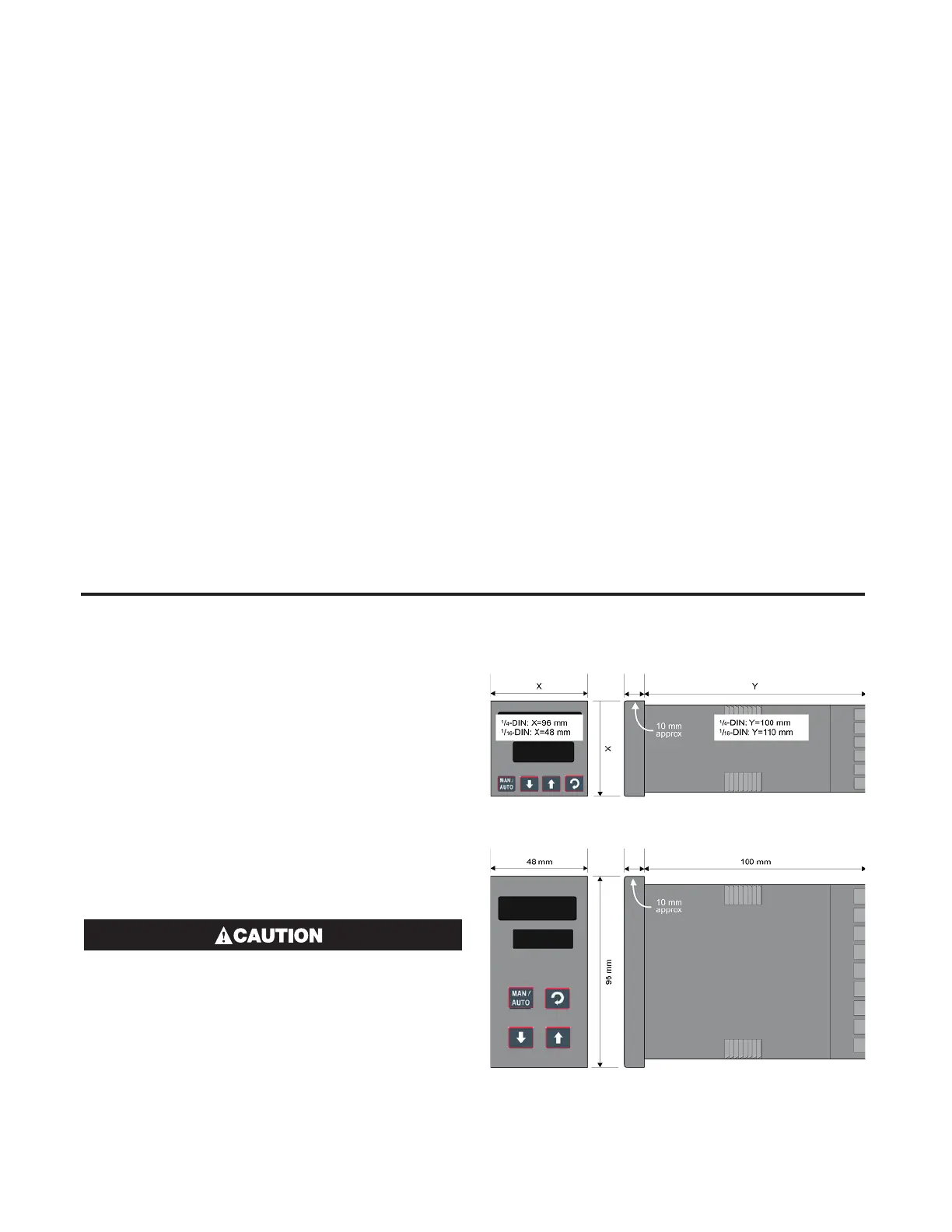

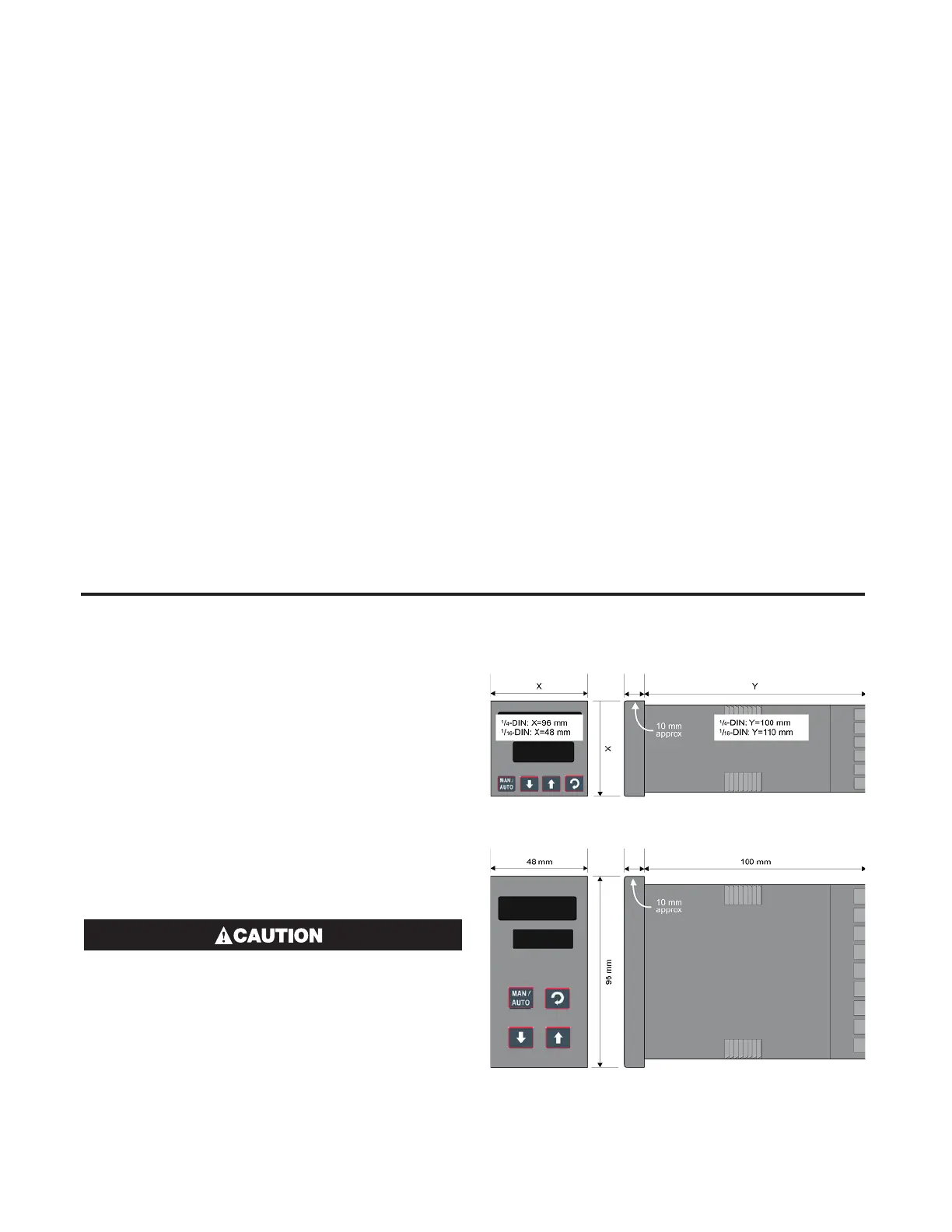

Figure 1. Main Dimensions

1/4 - DIN & 1/16 - DIN Instruments

1/8 - DIN Instruments

Loading...

Loading...