OIL PUMP INSPECTION

When disassembling the transaxle it is necessary

to inspect the oil pump for wear and damage.

(1) Remove the reaction shaft support bolts.

(2) Remove reaction shaft support from pump

housing (Fig. 174).

(3) Remove the pump gears and check for wear

and damage.

(4) Install the gears and check clearances.

(5) Measure the clearance between the outer gear

and the pump pocket (Fig. 175). Clearance should be

0.045-0.141mm (0.0018-0.0056 in.)

(6) Position an appropriate piece of Plastigage

across both pump gears.

(7) Align the Plastigage to a flat area on the reac-

tion shaft support housing.

(8) Install the reaction shaft to the pump housing.

Tighten the bolts to 27 N. M (20 ft. lbs.)

(9) Remove bolts and carefully separate the hous-

ings. Measure the Plastigage following the instruc-

tions supplied.

(10) Clearance between outer gear side and the

reaction shaft support should be 0.020-0.046mm

(0.008-0.0018 in.). Clearance between inner gear side

and the reaction shaft support should be 0.020-

0.046mm (0.008-0.0018 in.).

CAUTION: By-pass valve must be replaced if trans-

mission failure occurs.

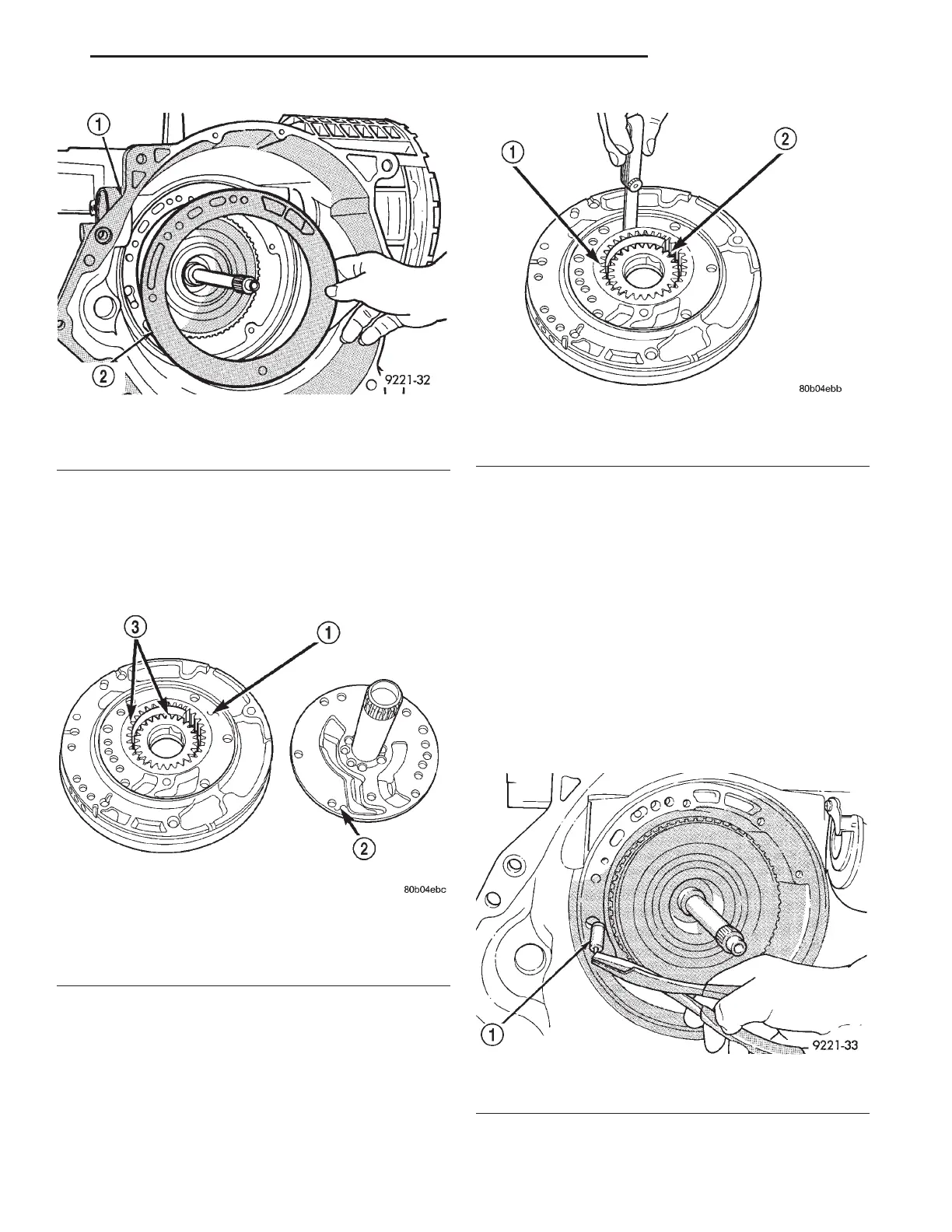

Fig. 173 Remove Oil Pump Gasket

1 – BELL HOUSING

2 – OIL PUMP GASKET

Fig. 174 Reaction Shaft Support

1 – PUMP HOUSING

2 – REACTION SHAFT SUPPORT

3 – PUMP GEARS

Fig. 175 Measure Outer Gear to Pocket

1 – OUTER GEAR

2 – POCKET

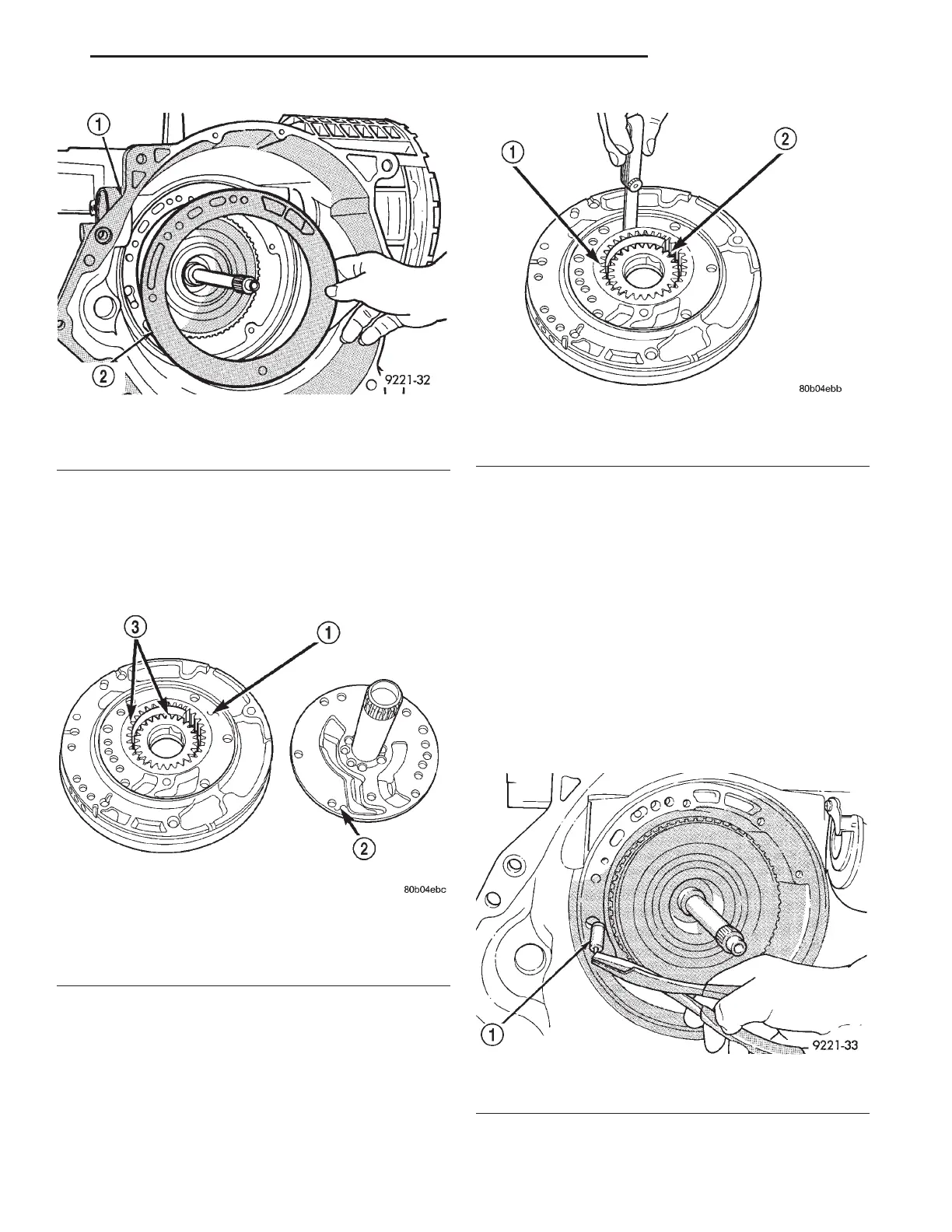

Fig. 176 Remove By-Pass Valve

1 – BY-PASS VALVE

LH 42LE TRANSAXLE 21 - 71

DISASSEMBLY AND ASSEMBLY (Continued)

Loading...

Loading...