Tighten new output shaft nut to 271 N·m (200 ft.

lbs.).

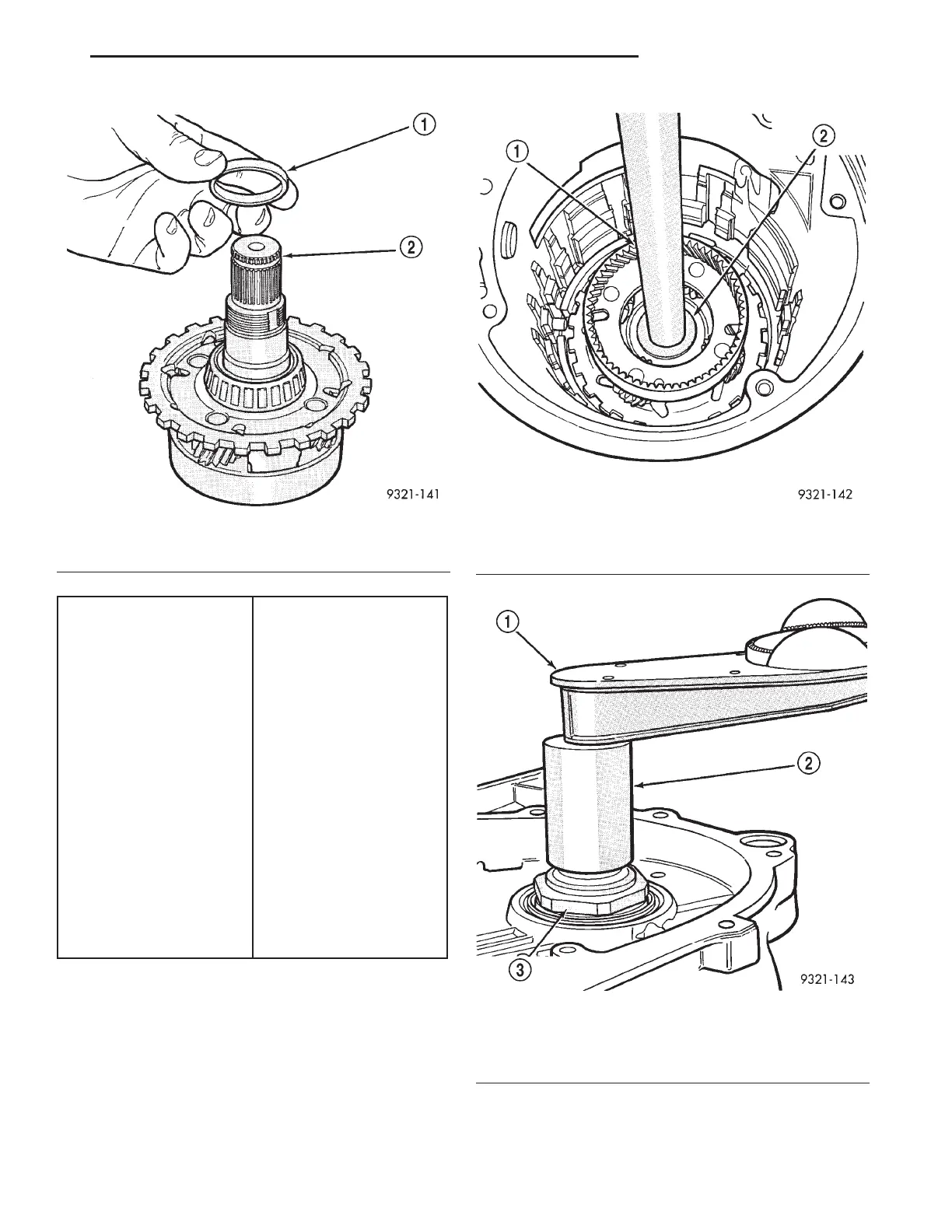

(7) Check the turning torque of the output shaft

(Fig. 309). The shaft should have 1 to 8 in. lbs. of

turning torque. If the turning torque is higher than

8 in. lbs., install a thicker shim. If the turning torque

is less than 1 in. lb., install a thinner shim. Make

sure there is no end play.

CAUTION: Failure to stake shaft nuts could allow

the nuts to back-off during use.

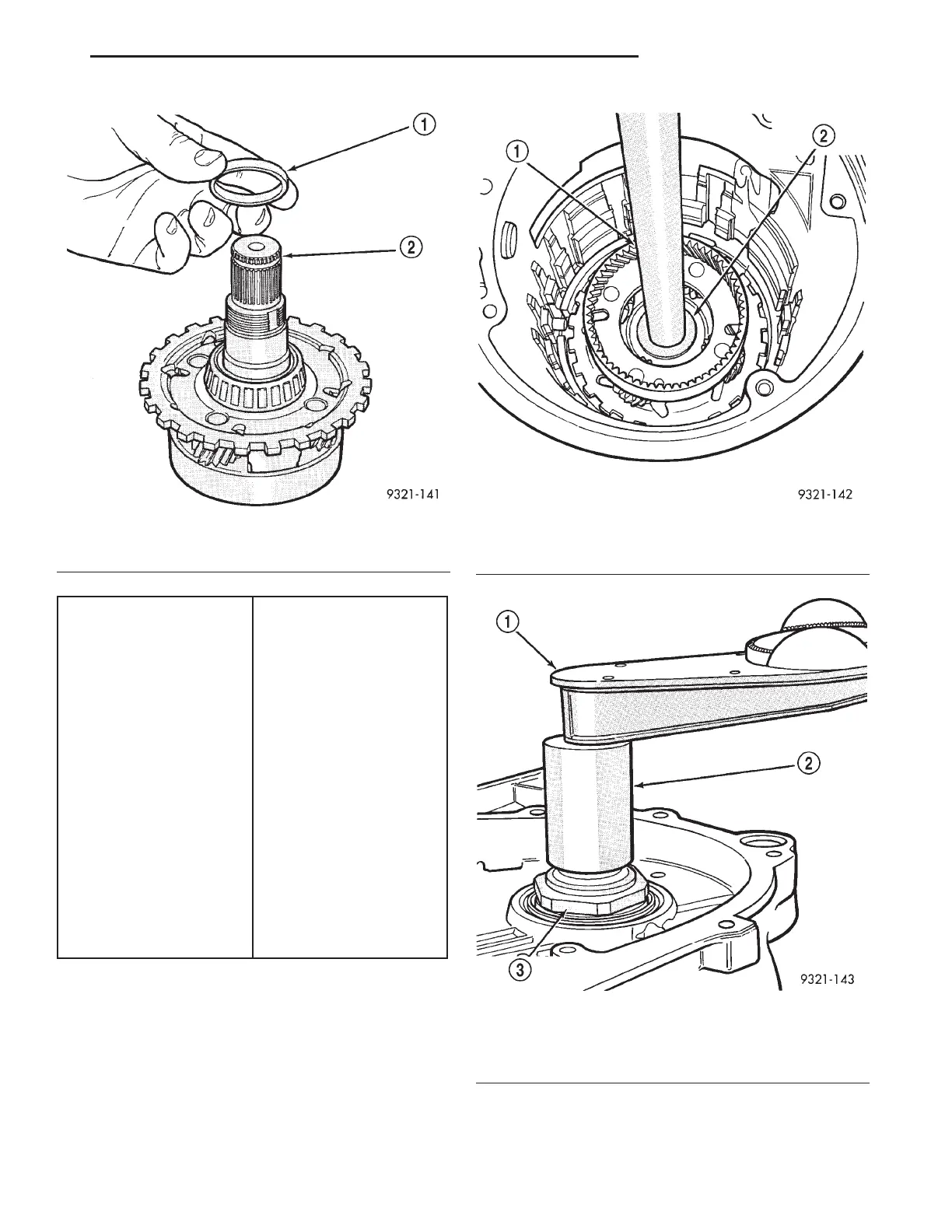

Fig. 307 Shim Installation

1 – SHIM

2 – OUTPUT SHAFT

5.17 - 5.19 mm 5.62 - 5.64 mm

5.20 - 5.22 mm 5.65 - 5.67 mm

5.23 - 5.25 mm 5.68 - 5.70 mm

5.26 - 5.28 mm 5.71 - 5.73 mm

5.29 - 5.31 mm 5.74 - 5.76 mm

5.32 - 5.34 mm 5.77 - 5.79 mm

5.35 - 5.37 mm 5.80 - 5.82 mm

5.38 - 5.40 mm 5.83 - 5.85 mm

5.41 - 5.43 mm 5.86 - 5.88 mm

5.44 - 5.46 mm 5.89 - 5.91 mm

5.47 - 5.49 mm 5.92 - 5.94 mm

5.50 - 5.52 mm 5.95 - 5.97 mm

5.53 - 5.55 mm 5.98 - 6.00 mm

5.56 - 5.58 mm 6.01 - 6.03 mm

5.59 - 5.61 mm 6.04 - 6.06 mm

Output Shaft Rear Shim Chart

Fig. 308 Press Shaft Into Case

1 – SPECIAL TOOL C-4171 AND C-4171–2

2 – SPECIAL TOOL MD-998911

Fig. 309 Checking Turning Torque

1 – TORQUE WRENCH

2 – SPECIAL TOOL 6498

3 – OUTPUT SHAFT NUT

LH 42LE TRANSAXLE 21 - 105

DISASSEMBLY AND ASSEMBLY (Continued)

Loading...

Loading...