DETERMINING No. 4 THRUST PLATE

THICKNESS—INPUT SHAFT END PLAY

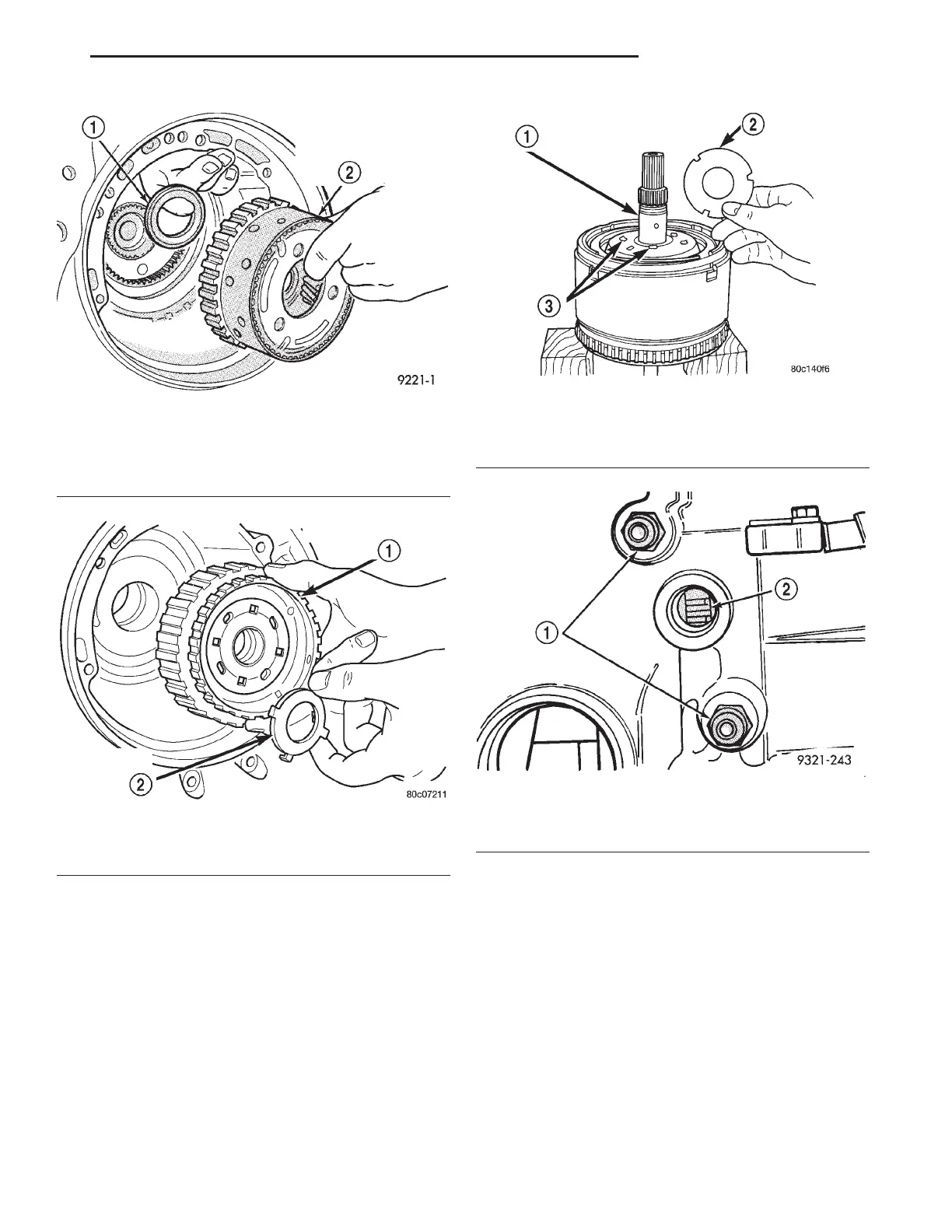

To determine the proper thickness of the No. 4

thrust plate, select the thinnest No. 4 thrust plate.

Using petrolatum (Fig. 340) to hold thrust plate in

position, install input clutch assembly. Be sure the

input clutch assembly is completely seated (Fig. 341).

CAUTION: If view through input speed sensor hole

is not as shown above, the input clutches assembly

is not seated properly.

Remove the oil pump O-ring (Fig. 342). You will be

able to install and remove the oil pump and gasket

very easily to select the proper No. 4 thrust plate.

NOTE: Use screw-in dowels or phillips-head screw-

drivers to align pump to case.

CAUTION: Be sure to reinstall O-ring on oil pump

after selecting the proper No. 4 thrust plate.

Measure the input shaft end play with the tran-

saxle in the vertical position. This will ensure that

the measurement will be accurate.

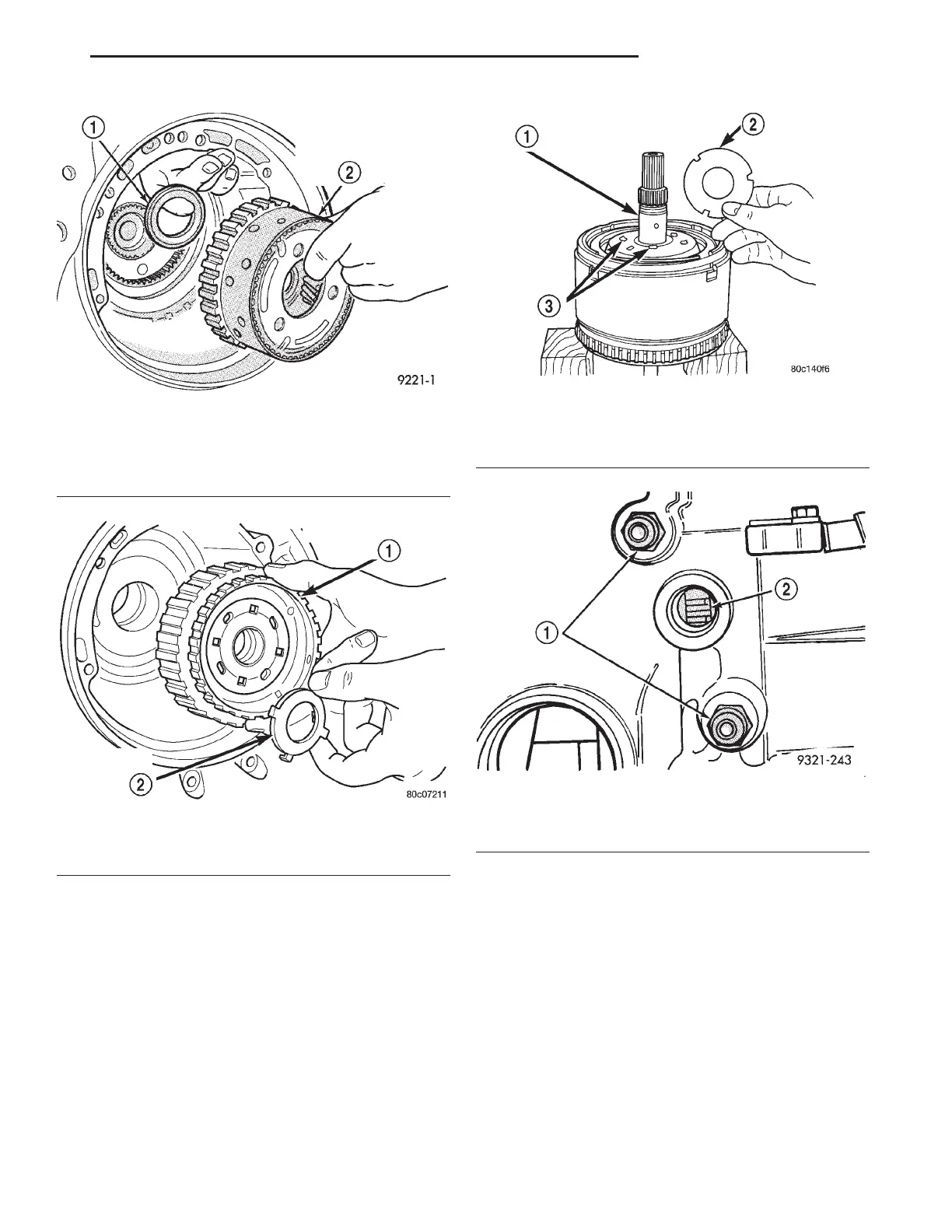

Fig. 338 Install Front Carrier and Rear Annulus

Assembly

1 – #6 NEEDLE BEARING

2 – FRONT CARRIER AND REAR ANNULUS ASSEMBLY (TWIST

AND PULL OR PUSH TO REMOVE OR INSTALL).

Fig. 339 Install Front Sun Gear Assembly

1 – FRONT SUN GEAR ASSEMBLY

2 – #4 THRUST WASHER (FOUR TABS)

Fig. 340 Select Thinnest No. 4 Thrust Plate

1 – OVERDRIVE SHAFT ASSEMBLY

2 – #4 THRUST PLATE (SELECT)

3 – 3 DABS OF PETROLATUM FOR RETENTION

Fig. 341 View Through Turbine Speed Sensor Hole

1 – TRANSAXLE COOLER LINE

2 – TURBINE SPEED SENSOR HOLE

LH 42LE TRANSAXLE 21 - 113

DISASSEMBLY AND ASSEMBLY (Continued)

Loading...

Loading...