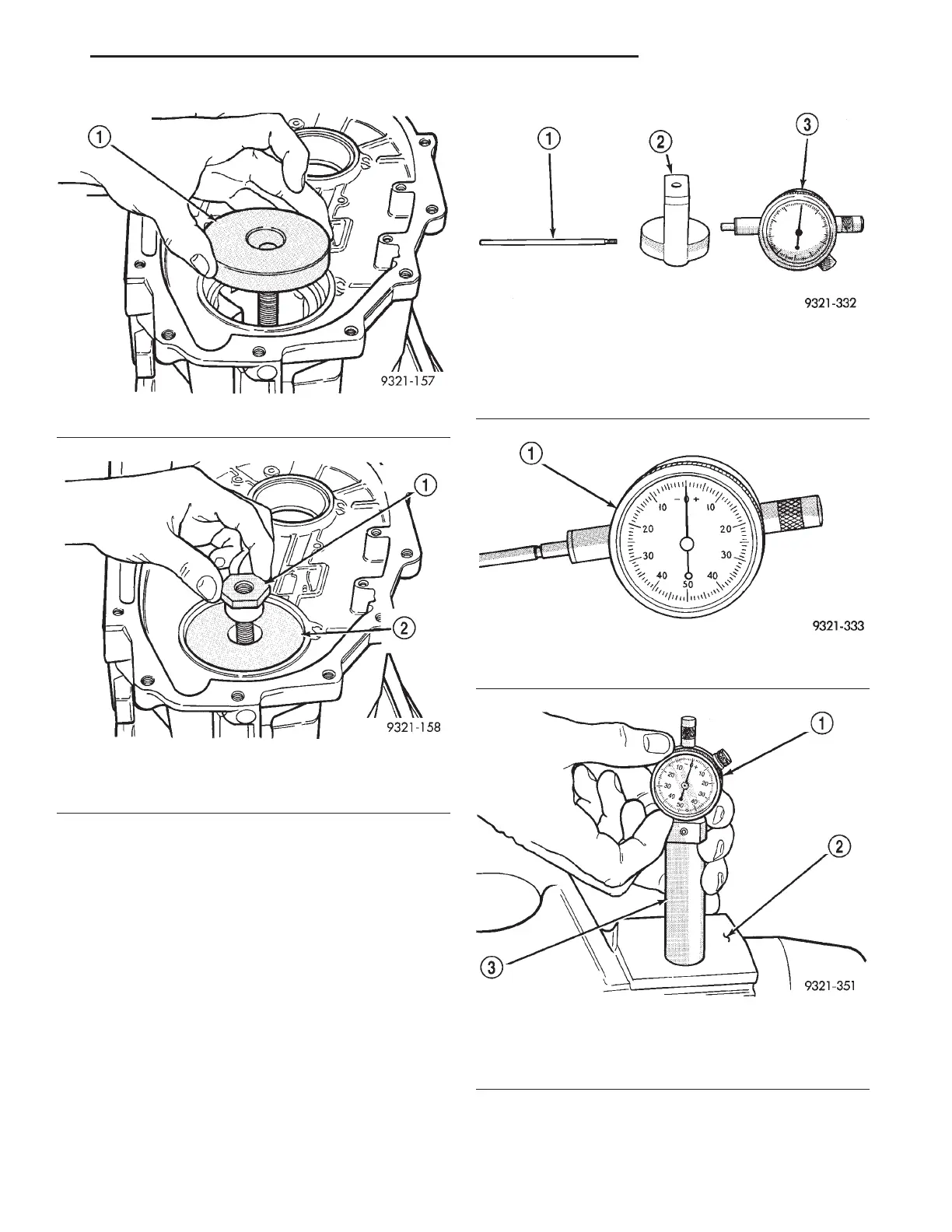

(8) Install dial indicator into locating block Tool

6549-1. Then screw extension rod onto dial indicator.

NOTE: The dial indicator used to make this mea-

surement must have a face that shows 0-50-0 (Spe-

cial Tool C-3339) readings (Fig. 396). All steps from

this point forward will reflect this assumption. This

will give you proper shim thickness.

(9) Before making a pinion depth measurement

the dial indicator must be zeroed. This is done by

placing the dial indicator in the zeroing fixture (spe-

cial tool 6549-6). Then place the zeroing fixture on a

flat surface. Adjust the dial face so the pointer on the

dial indicator lines up with the zero (Fig. 397).

(10) Compress the dial indicator slightly and

insert dial indicator pin into centering block (Fig.

398).

(11) Pivot dial indicator back and forth (Fig. 399)

on centering pin to obtain the shortest distance mea-

surement. This will be the lowest number read-

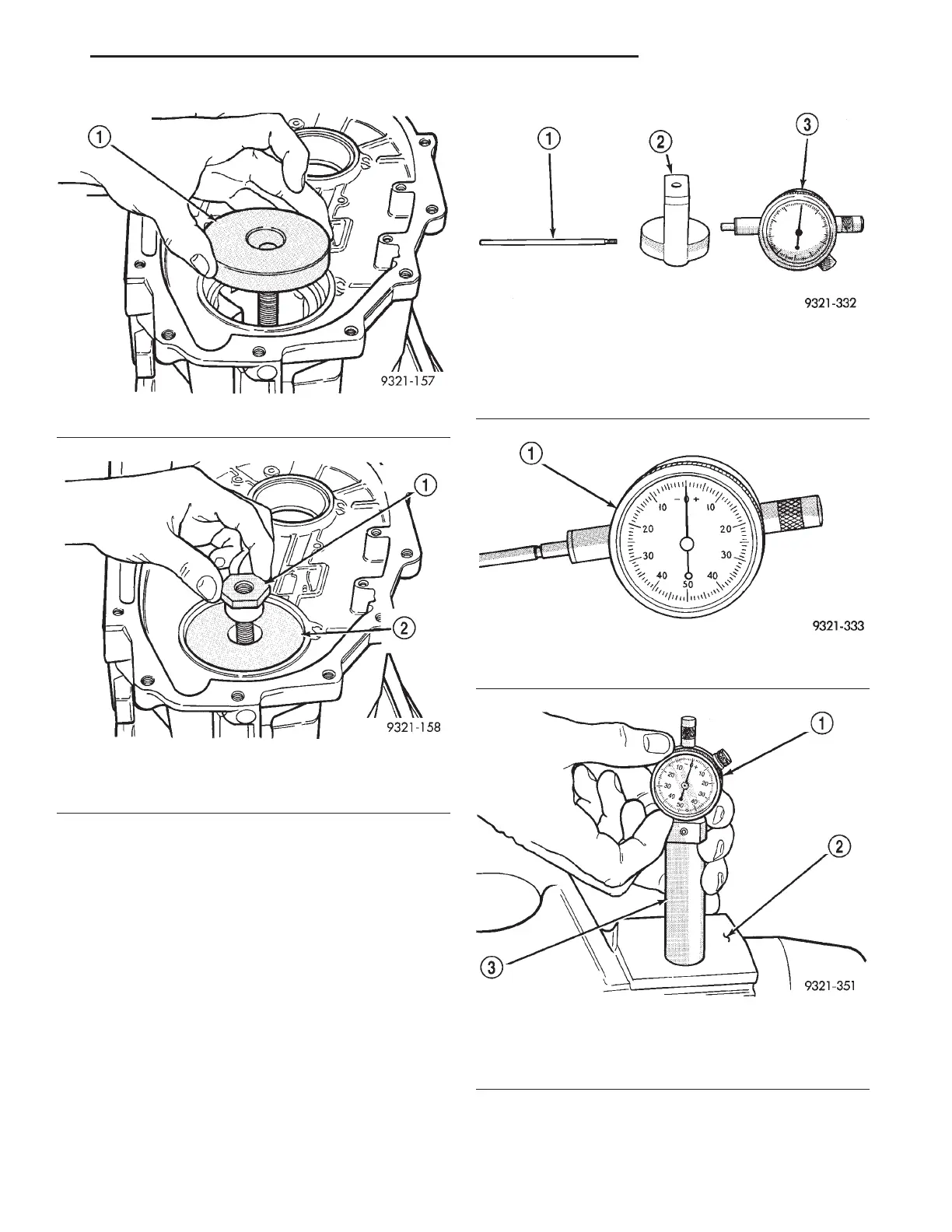

Fig. 393 Disc Installation

1 – SPECIAL TOOL 6494–2

Fig. 394 Installing Centering Nut

1 – CENTERING NUT

2 – CENTERING DISC

(6494–2)

Fig. 395 Dial indicator, Locating Block and

Extension Rod

1 – EXTENSION ROD SPECIAL TOOL

2 – LOCATING BLOCK SPECIAL TOOL

3 – DIAL INDICATOR

Fig. 396 0-50-0 Dial Indicator

1 – DIAL INDICATOR

Fig. 397 Zero Dial Indicator

1 – DIAL INDICATOR

2 – FLAT SURFACE

3 – ZEROING FIXTURE

LH 42LE TRANSAXLE 21 - 127

DISASSEMBLY AND ASSEMBLY (Continued)

Loading...

Loading...