ing on dial indicator. Record the number obtained.

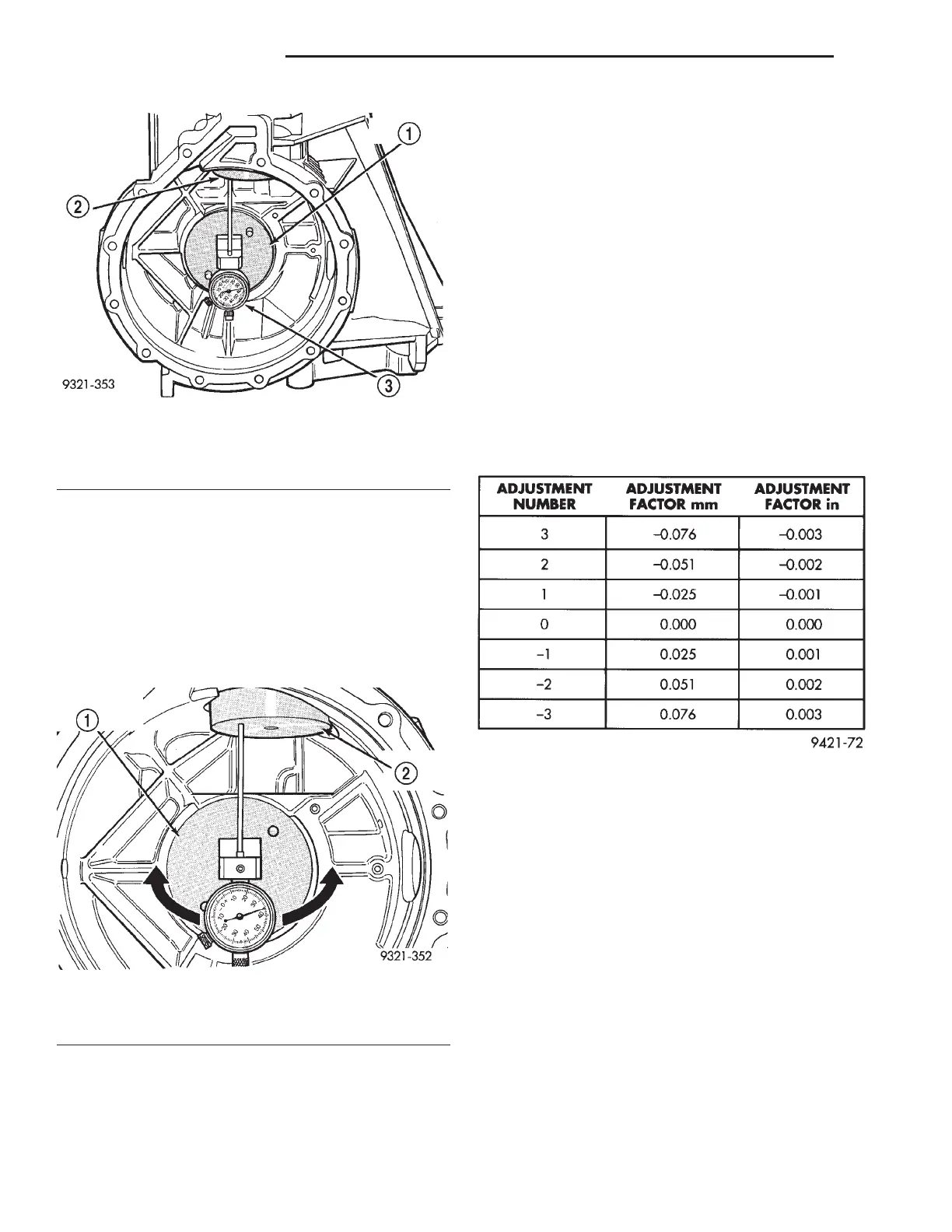

Now rotate the gauge disc clockwise 1/3 of a turn and

recheck readings. Record number obtained. Rotate

the gauge disc another 1/3 of a turn clockwise and

take another reading. Average the three readings.

Record this pinion depth measurement. If the read-

ings differ by more than two thousandths recheck

guage disc installation, it may have been installed

slightly cocked.

(12) To determine the required shim thickness, the

pinion depth measurement must be adjusted. The

pinion shim adjustment number is the first of seven

digits ink stamped on the shank of the transfer shaft

(Fig. 400). Using the adjustment factor chart, convert

the adjustment number to the corresponding adjust-

ment factor. Utilizing the pinion depth measurement

obtained in Step 11, add or subtract the adjustment

factor to calculate the requred shim thickness. Refer

to pinion head shim chart for shim selections. This is

the shim that will be installed between the transfer

shaft pinion head and the front transfer shaft bear-

ing. Refer to the following examples for further

explanation:

(13) Example 1 in (MM):

• Measured pinion shim depth: 0.789mm

• Adjustment number on transfer shaft: +2

• Adjustment factor (mm): -0.051mm

• Shim size needed: 0.789-0.051= 0.738mm

(14) Example 2 in (IN):

• Measured pinion shim depth: 0.032in

• Adjustment number on transfer shaft: -1

• Adjustment factor (in): +0.001

• Shim size needed: 0.032+0.001= 0.033in

(15) Remove dial indicator, gauge disc and center-

ing block from transaxle.

(16) Install shim selected in Step 12 of this proce-

dure onto the transfer shaft (Fig. 400).

(17) Press front transfer shaft bearing onto trans-

fer shaft (special tool 6052). The shim must be in

place before pressing on bearing (Fig. 401).

(18) At this point the pinion depth has been deter-

mined and the shim has been installed onto the

transfer shaft. Before the pinion is installed into the

transaxle case, bearing preload must be determined

for the differential bearings. The following steps

must be performed before the pinion is installed.

(19) The following steps will determine how many

foot pounds are required on the outer differential

adjuster to obtain the correct turning torque.

CAUTION: Failure to set differential bearing preload

correctly may cause bearing failure, gear noise

and/or axle shaft seal failure.

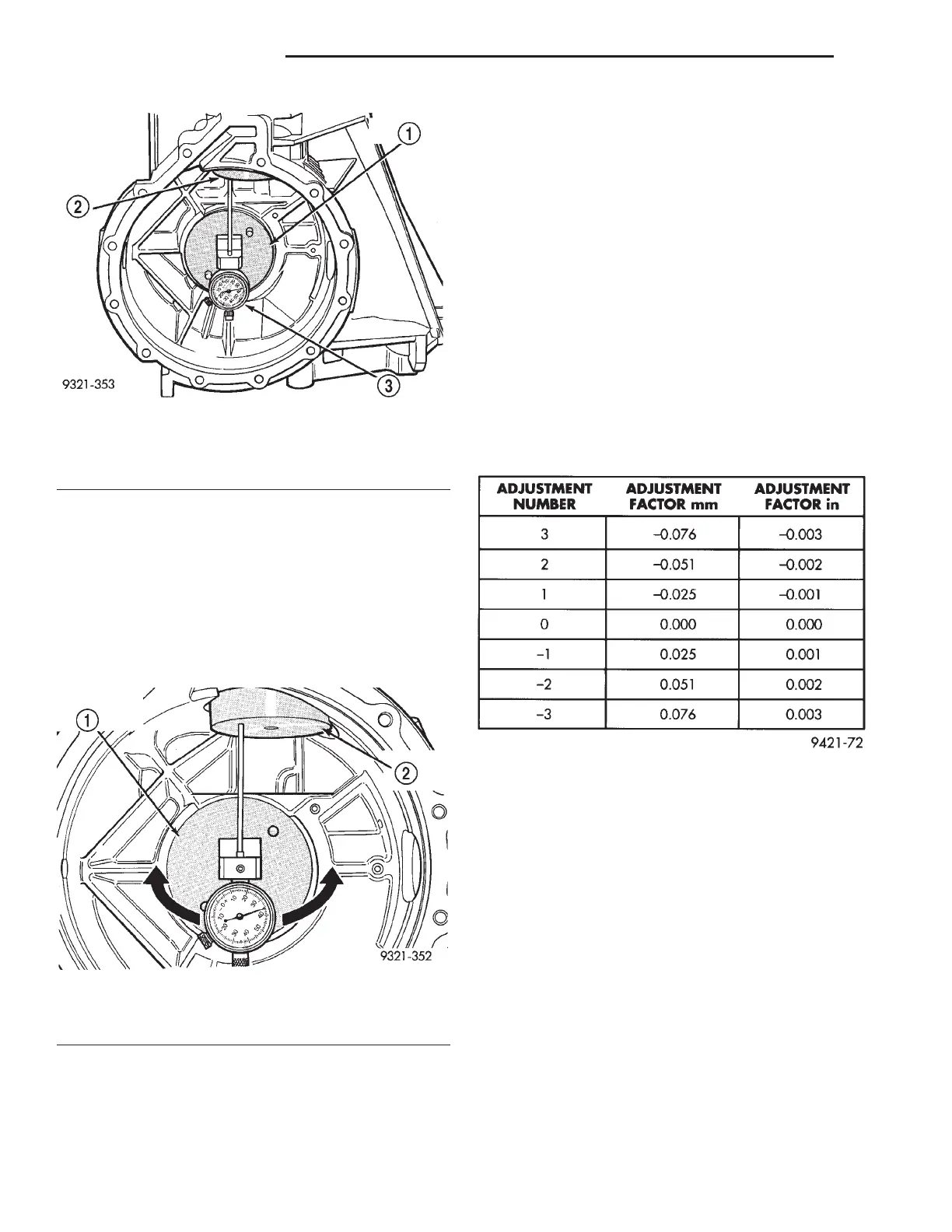

Fig. 398 Mounting Dial Indicator to Centering Block

1 – CENTERING BLOCK

2 – GAUGE DISC

3 – DIAL INDICATOR

Fig. 399 Pivot Dial Indicator

1 – CENTERING BLOCK

2 – GAUGE DISC

ADJUSTMENT FACTOR CHART

21 - 128 42LE TRANSAXLE LH

DISASSEMBLY AND ASSEMBLY (Continued)

Loading...

Loading...