Installation

- 80 -

Notes:

(1) Ensure quality of user supplied connecting pipe. Before connection, clean inside of pipe

and prepare bell mouths. You can order these from our factory.

(2) Site fabrication of bell mouths must use special pipe-expander to avoid F22 leak after

installed.

(3) Use two spanners to tighten connection between indoor unit and connecting pipe;

otherwise indoor unit tubing may twist, deform or even break.

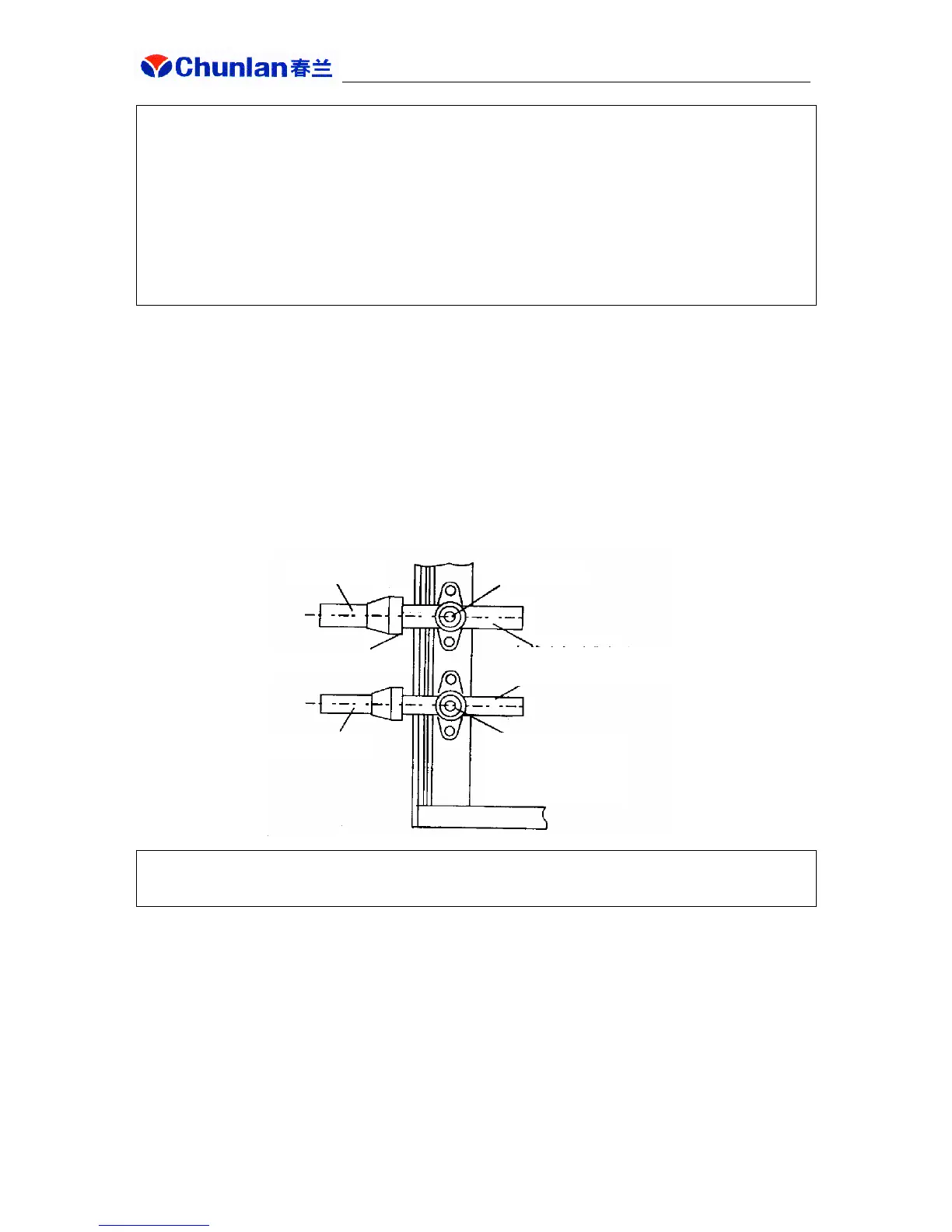

4. Venting of system

(1) Loosen nut on upper air pipe (large pipe) of outdoor unit large shutoff (ball) valve by half

a round;

(2) Unscrew valve core nut on the two valves;

(3) Open small shutoff (or ball) valve core by one round. When you feel that air coming out of

air pipe nut on the large shutoff (or ball) valve is cold, this means that air is basically vent.

Immediately tighten air pipe nut with spanner. Then open both shutoff (ball) valve cores, put

on valve core nuts and tighten.

Note: Use of the unit without opening all valve cores will cause failure or poor performance.

When ball valve core is rotated parallel to pipeline axis, the valve is open.

5. System leakage detection

(1) Fully open large and small shutoff (or ball) valve cores to detect leakage; confirm no

refrigerant leakage;

(2) Halogen mutual detection meter shall be used for detection, or apply soapy water at

connections and valve cores etc.;

(3) In case of slight leakage, use spanner to tighten leaking connection till the leak vanishes;

otherwise it is necessary to correct threaded connector and bell mouth jointing face and

Steam pipe

Valve core nutValve core nut

Loosen half round before venting

Large shutoff (ball) valve

Small shutoff (ball) valve

Liquid pipe

For venting, unscrew nu

Loading...

Loading...