© CIAS Elettronica S.r.l. Ed. 1.0

Installation Handbook page 47 of 59 MANTA 50 – 80

5. MAINTENANCE AND ASSISTANCE

5.1 Troubleshooting

In case of false alarm, check the parameters recorded during the Installation phase (on

attached Test Sheet), if there are divergences with permitted limits check again the related

points in chapter "Adjustment and Testing (4)"

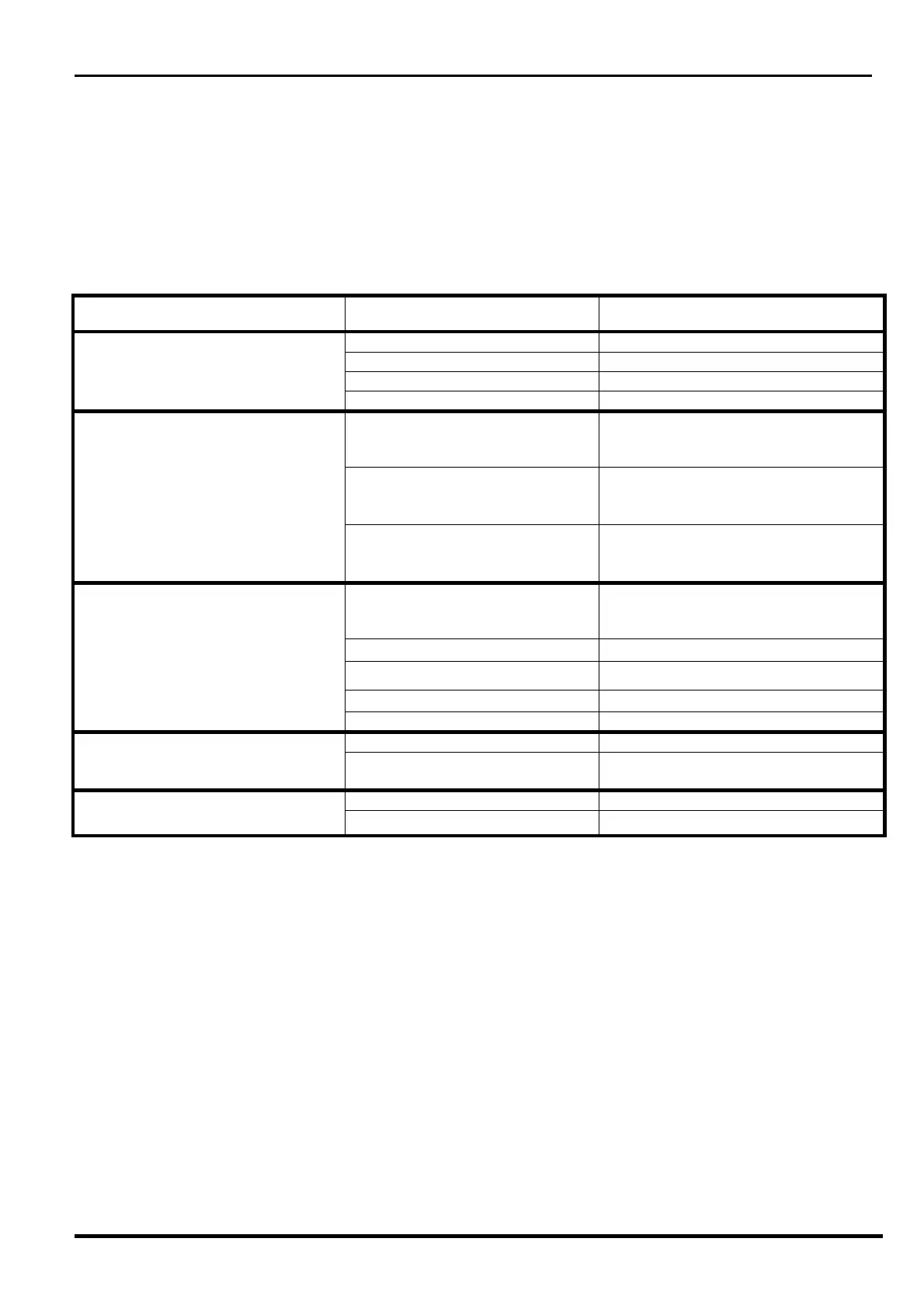

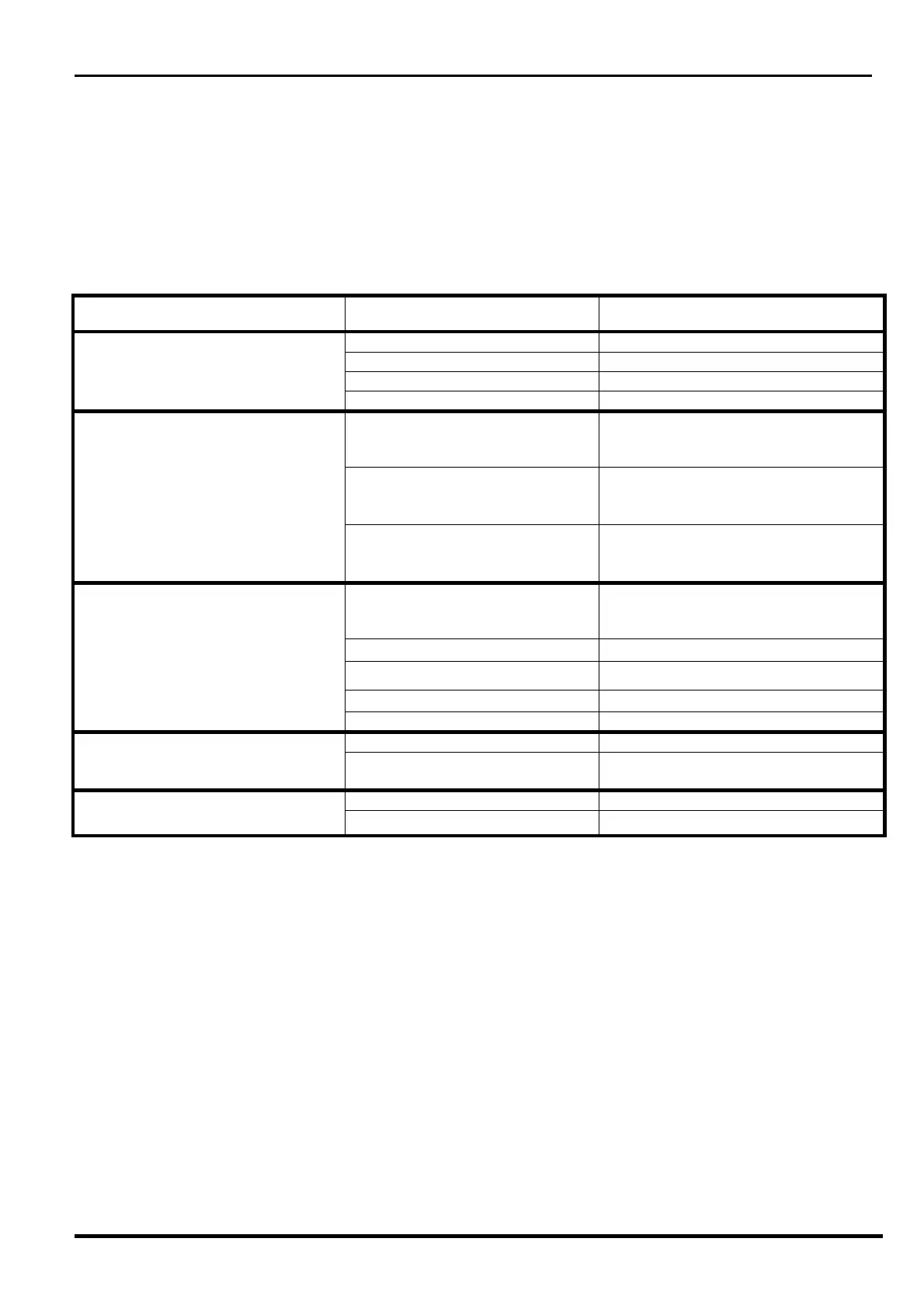

Defect Possible Cause Possible Solution

Power too high or too low Check the power supply voltage

Temperature too high or too low Check the temperature of the barrier

Tx Oscillator Fault Change the Oscillator

Fault Led ON

Tx or Rx failures Change the Electronic board

Movement or obstacles in the

protected field

Check out that the protected field is

free from obstacles and free from

objects and/or person moving.

Barrier not properly aligned Re do the alignment procedure as

described in points: a,b,c,d,e,f,g,h,i of

charter 4.1.2

Alarm Led ON

Wrong channel selections Do again the Channel acknowledge

procedure as described in point b, j of

charter 4.1.2

Barrier not properly aligned Re do the alignment procedure as

described in points: a,b,c,d,e,f,g,h,i,j

of charter 4.1.2

obstacles in the protected field Remove obstacles

Too low signal transmitted Check the transmitter

Rx circuit fault Change the Rx circuit

High AGC Voltage

Rx MW part fault Change the RX MW part

Micro switch open Check the micro switch position Tamper Led ON

Tilt bulb in wrong position Check the position of the tilt bulb

(Vertical)

BF Oscillator Fault Change the TX circuit Fault Led ON only on TX circuit

MW oscillator Fault Change the MW part

5.2 Maintenance kits

The Maintenance Kits are composed by circuits equipped with microwave cavities, their

substitution is very easy:

The circuit and cavity substitution on boot transmitter and receiver heads doesn’t

changes the heads alignment, and so no new alignment is required

Loading...

Loading...