2 - 22

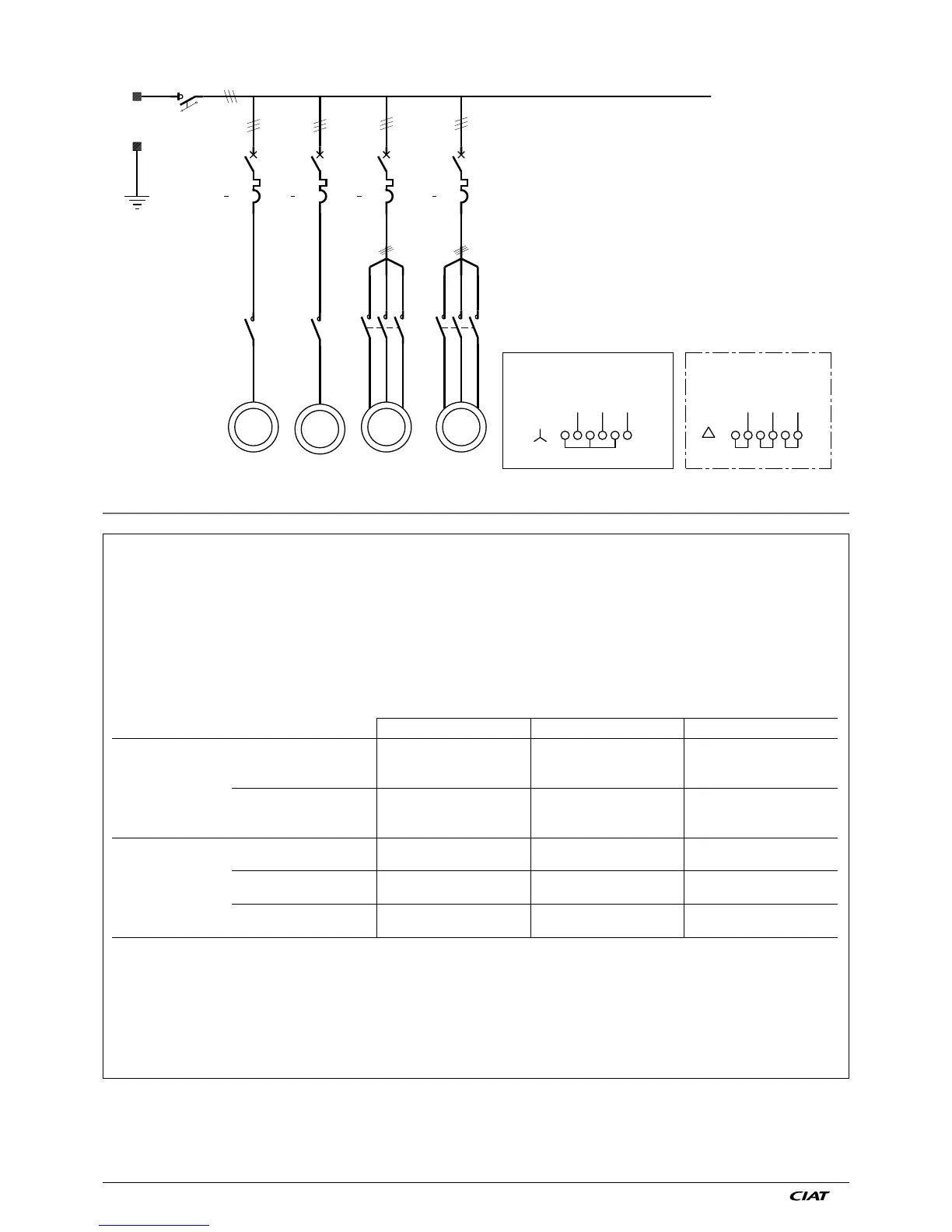

QC2

LOW SPEED

WIRING

HIGH SPEED

WIRING

29 - ECODESIGN

The sealing test must be carried out in compliance with EC regulation no. 517/2014 relating to certain greenhouse gases.

R410A, R134a and R407C are refrigerant gases with the following environmental impact:

1/ No impact on the ozone layer.

They have an ODP (Ozone Depletion Potential) index of 0

2/Impact on the greenhouse effect: Global Warming Potential (GWP) of each gas.

- R410A -------- GWP = 2088

- R407C -------- GWP = 1800

- R134a -------- GWP = 1430

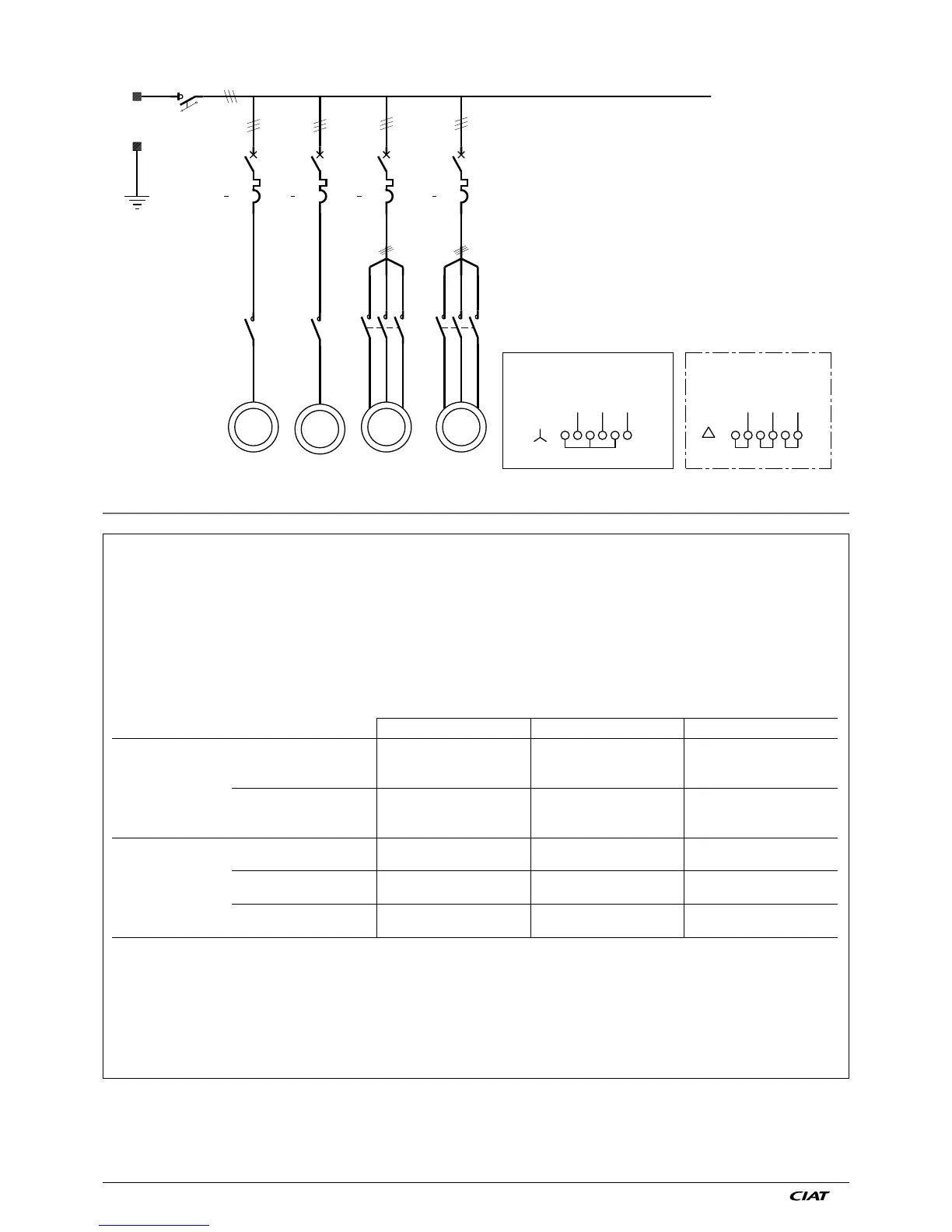

- Users must ensure that periodic leak testing is carried out by qualified personnel based on the number of tonnes of CO

2

equivalent:

≥ 5 tCO2eq ≥ 50 tCO2eq ≥ 500 tCO2eq

Test interval

Without leak detection system Every 12 months Every 6 months Every 3 months

With leak detection system Every 24 months Every 12 months Every 6 months

Refrigerant uid

charge*

R410A (GWP = 2088) ≥ 2.39 kg ≥ 23.9 kg ≥ 239 kg

R407C (GWP = 1800) ≥ 2.77 kg ≥ 27.7 kg ≥ 277 kg

R134a (GWP = 1430) ≥ 3.49 kg ≥ 34.9 kg ≥ 349 kg

* To find out the refrigerant charge and the number of tonnes of CO

2

equivalent, refer to the technical characteristics in the

unit's instruction manual.

- Users of any system subject to leak testing are required to keep a log of the quantities and types of fluids used, (added or

recovered), and to include the dates and results of leak tests, as well as the name of the technician and the technician's

company.

- A leak test must be carried out one month after any leak repairs.

- System users are responsible for collecting used refrigerant and having it recycled, regenerated or destroyed.

Loading...

Loading...