10 11

EN EN

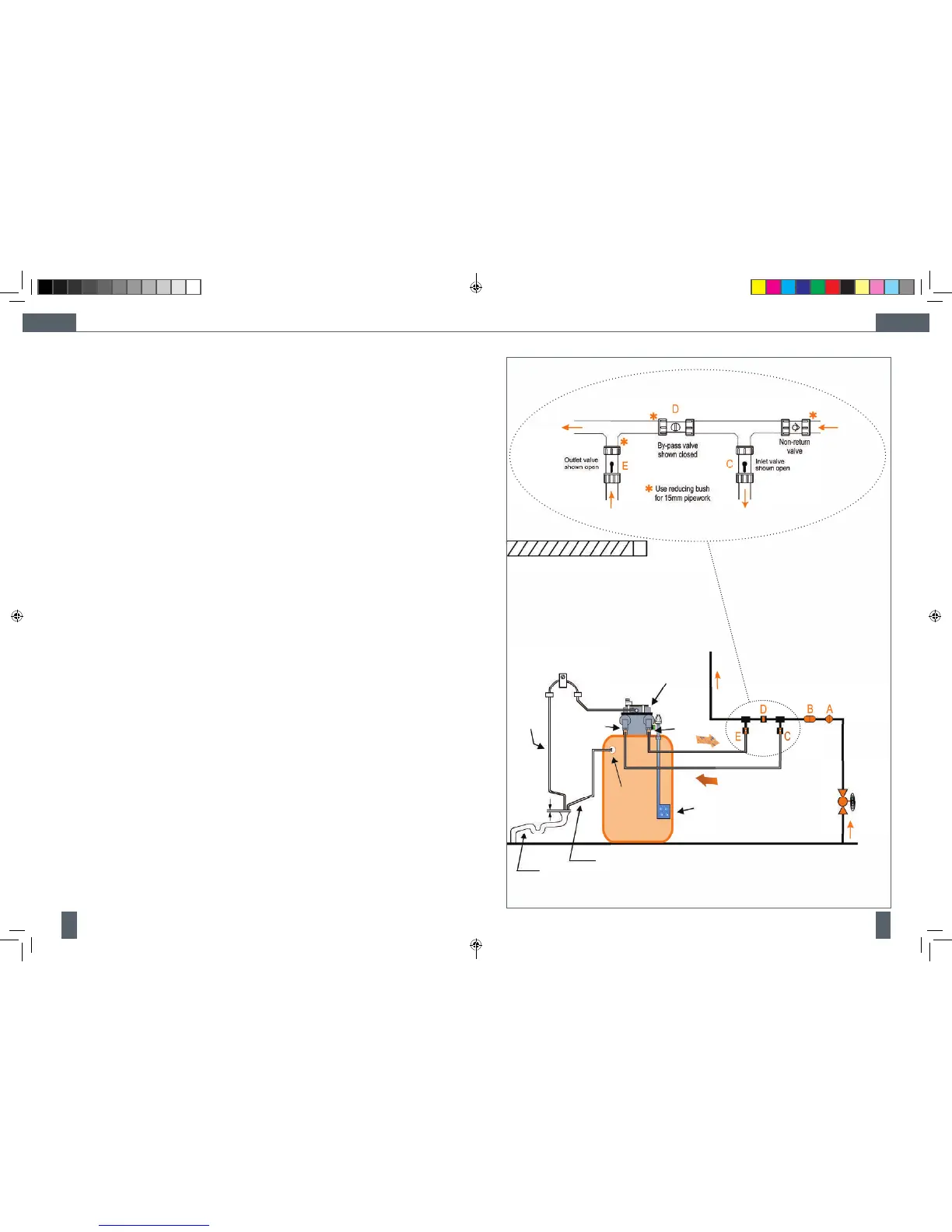

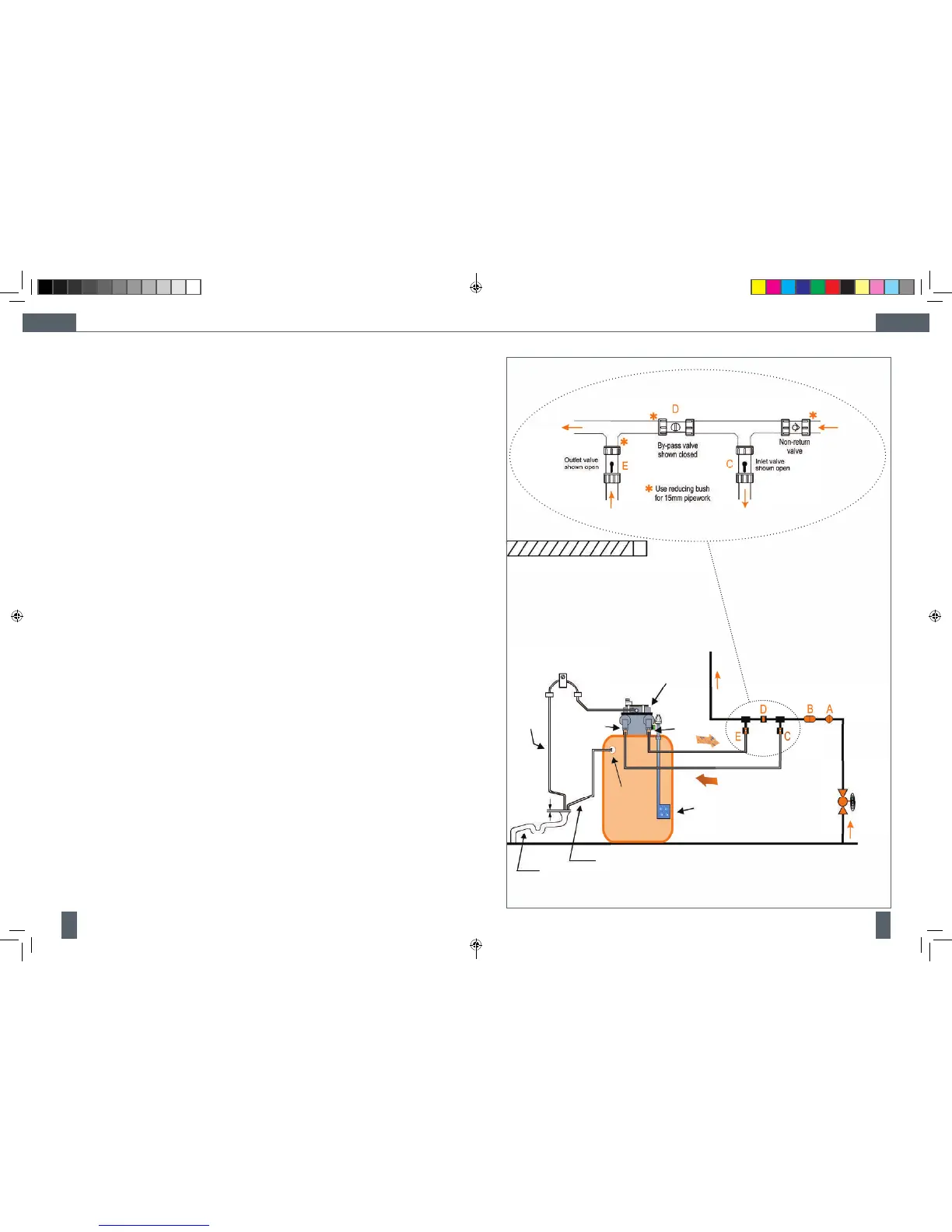

3. Loft installation

The water softener should be installed within a con-

tainer of not less than 100 litre capacity, to which

there should be connected an over ow pipe of not

less than 20mm diameter. The over ow should be

connected at the bottom of the container and not

less than 15mm below the height of any electrical

components mounted on the water softener. It is

recommended that an anti vacuum valve be tted

to the inlet pipework supplying the water softener.

4. Plumbing systems

There are several types of plumbing systems in

common use:

For 15mm pipework (e.g.Static Head systems)

The water softener can be supplied optionally

with a high ow installation kit and exible high

ow hoses suitable for 22mm pipework, for 15mm

pipework use the reducing bushes supplied with

the kit, (see diagram on page 11).

5. Back ow prevention device

When tted to the supply feeding a single dwelling,

a check valve complying with national regulations

must be tted on the cold water feed prior to the

installation. All other types of installation require the

tting of a double check valve.

6. Drinking water

Your water softener installation must include at

least one drinking water tap that is not fed by the

water softener.

In case of low sodium diet follow the local

“department of health‘s“ advice concerning the use

of softened water for drinking.

Note: Water that is used for mixing powdered milk

for babies must only be taken from an unsoftened

mains tap as some powdered milks and softened

water both contain sodium for which young babies

have a limited tolerance.

7. Only original spare parts and accessories autho-

rized by the manufacturer guarantee operational

safety. Using non-authorized parts may void any

liability on the part of the manufacturer in case of

consequential damage.

I. Waste

water

hose

O.

Over ow *

G.

Brine storage

Cabinet

F. Mains stop valve

C. Inlet

M.

Valve Head

Rising Main

To rising

main

Inlet from

mains

Outlet from

softener

Inlet to

softener

3.4 Installation Layout

Water softener

K. Over ow exible hose

Key to the diagram:

A. Non return valve

B. Pressure reducing valve (where required)

C. Inlet valve ¾“

D. Bypass valve

E. Outlet valve ¾“

G. Brine storage cabinet

Observe a minimum distance to the ceiling (N) of 0.5 m.

J. Drainage (

* Existing or new “Trapped“ stand pipe or to external drainage)

H. Fixing clip

20 mm

Key to the diagram:

H. Fixing clip

I. Waste water hose

J. Drainage

K. Flexible hose, Over ow

L. Control valve (green)

M. Servo-motor for valve positioning

N. Distance device & ceiling of room

O. Over ow connection ½“

P. Waste water trap

E. OutletL.

N.

P.

OPM - Cillit Access 10-25 vOrange - EN, DEv4.indd 10-11 02/10/2012 09:48

Loading...

Loading...