Section 6. Planned Maintenance and Lubrication

6.9

Battery Handling

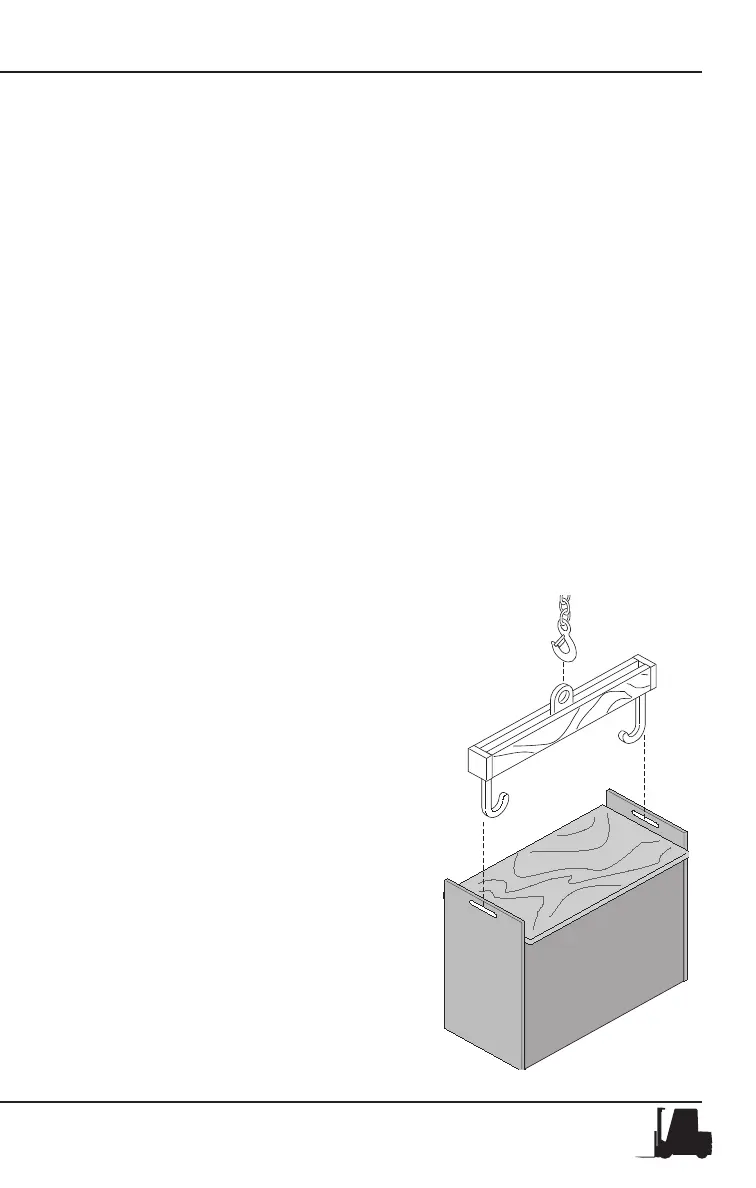

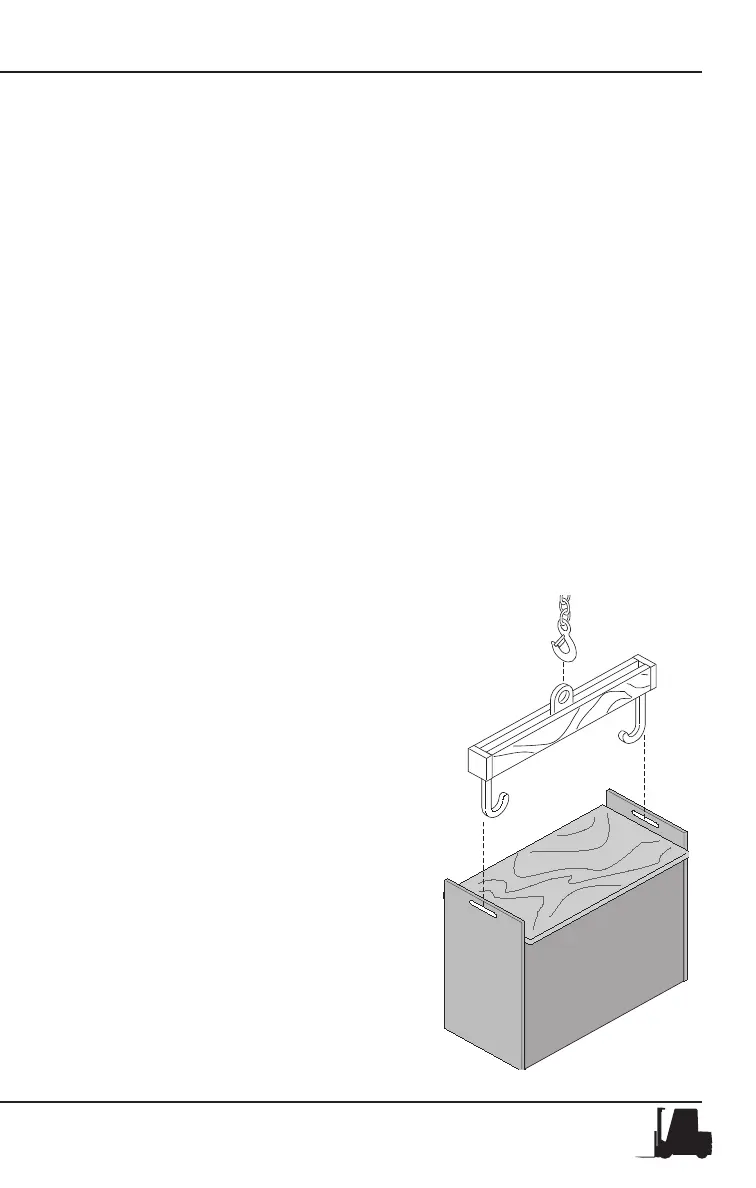

1. Change(remove)orservicestoragebatteriesonlyinanareades-

ignated for this purpose.

2. Besurethisareahasprovisionstoushandneutralizespillage,to

ventilatefumesfromgassingbatteries,andforreprotection.

3. Thisareashouldbeequippedwithmaterialhandlingtoolsdesigned

for removing and replacing batteries, including a conveyor or over-

head hoist. Use lift hooks that have safety latches.

4. Alwaysuseaspecialliftingdevicesuchasaninsultedspreader

bar to attach the hoist to the battery. The width of the spreader bar

must be the same as the lifting eyes of the battery, to prevent dam-

age to the battery. If the spreader bar hooks are movable, carefully

adjusttheposition(width)ofthehookssothatthepullisdirectly

upward(vertical)andnosideloadorforce(pressure)isexerted

on the battery case. Be sure the lift hooks are the correct size to

ttheliftingeyesofthebattery.

5. If the battery does not have a cover

ofitsownorhasexposedterminals

and connectors, cover the top with

anon-conductive(insulating)ma-

terial, such as a sheet of plywood or

heavy cardboard, prior to attaching

the lifting device.

Battery Handling

Loading...

Loading...