27

Scheduled fuel maintenance helps to reduce fuel degradation. Fuel maintenance filtration can remove

contaminants and water and maintain fuel conditions to provide reliability and efficiency for standby fire pump

engines. Fuel maintenance and testing should begin the day of installation and first fill.

A.8.3.4.2 Where environmental or fuel quality conditions result in degradation of the fuel while stored in the

supply tank, from items such as water, micro-organisms and particulates, or destabilization, active fuel

maintenance systems permanently installed on the fuel storage tanks have proven to be successful at

maintaining fuel quality. An active fuel maintenance system will maintain the fuel quality in the tank, therefore

preventing the fuel from going through possible cycles of degradation, risking engine reliability, and then

requiring reconditioning.

Bleeding the Fuel System

CAUTION: Escaping fluid under pressure can penetrate the skin causing series injury. Relieve pressure before

disconnecting fuel or other lines. Tighten all connections before applying pressure. Keep hands and body

away from pinholes and nozzles, which eject fluids under high pressure. Use a piece of cardboard or paper to

search for leaks. Do not use your hand. If ANY fluid is injected into the skin, it must be surgically removed

within a few hours by a doctor familiar with this type injury or gangrene may result. Ref Figure 4-1

Figure 4-1

Whenever the fuel system has been opened up for service (lines disconnected, or filters removed), it will be

necessary to bleed air from the system.

Priming the C18 Engine when secondary filter has been changed.

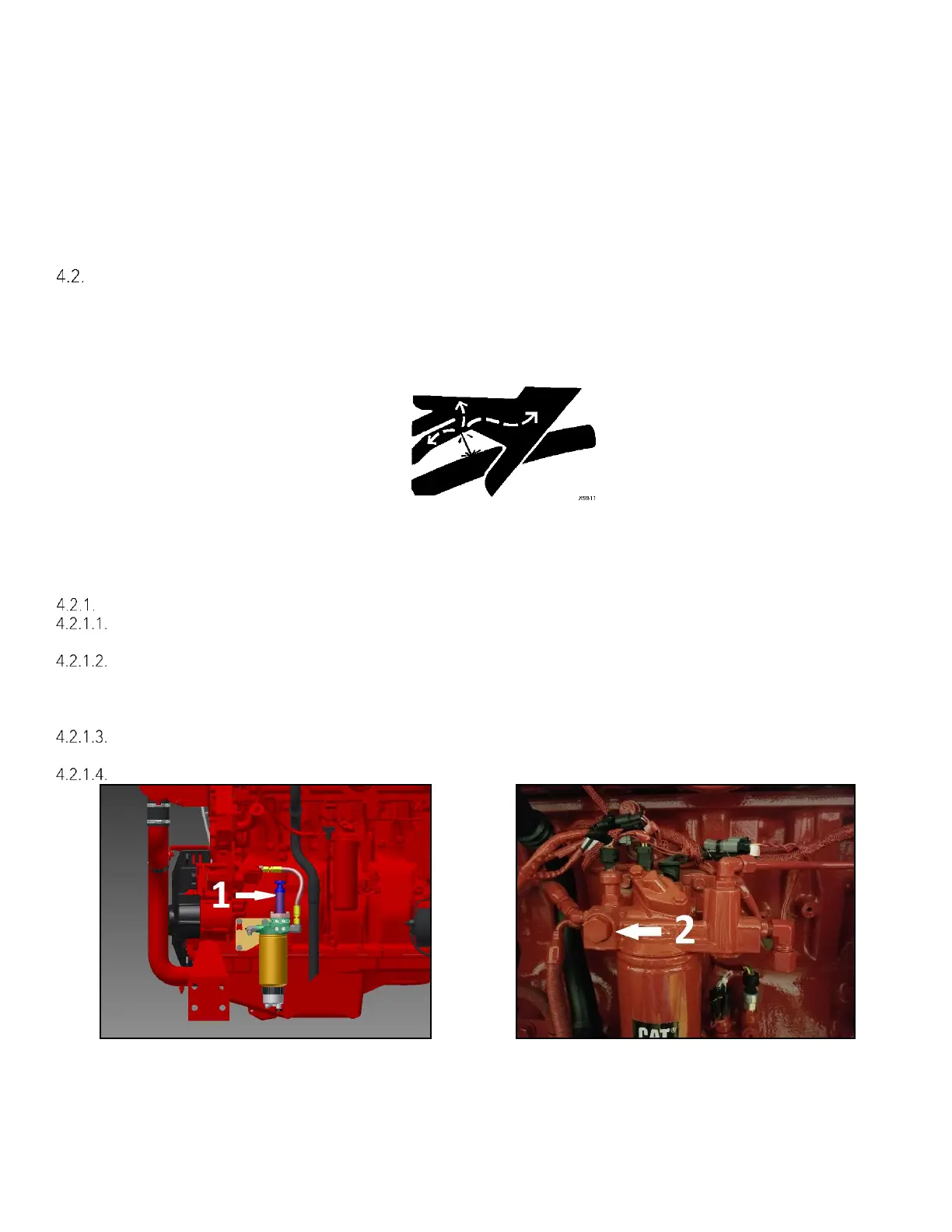

Open the air purge screw (2) three full turns. Do not remove screw. The air purge screw is located on the

secondary filter base. See Figure #4-3.

Start the engine. The engine should start and run smoothly. Never crank the engine for more than 30 seconds

continuously. Allow the starter motor to rest for 2 minutes after 30 seconds of cranking. You may use the hand

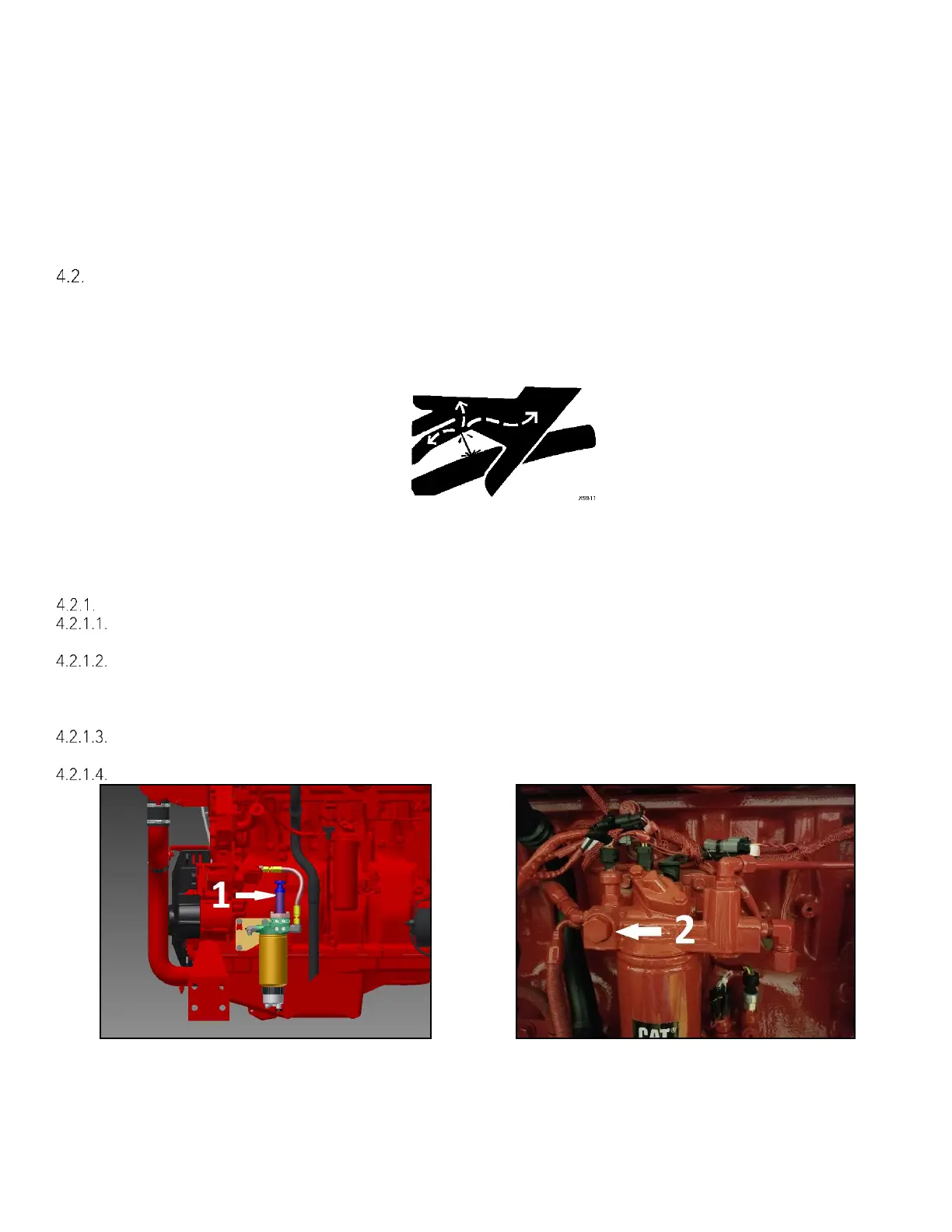

priming pump (1), in lieu of starting the engine. The priming pump is located on the primary filter base on your

Clarke C18 engine. See Figure #4-2.

While the engine is running, monitor the air purge screw (2). When a small drop of fuel appears at the threads,

turn and tighten air purge screw. The tone of the engine may change as the screw is tightened, this is normal.

Clean residual fuel from all engine components.

Loading...

Loading...