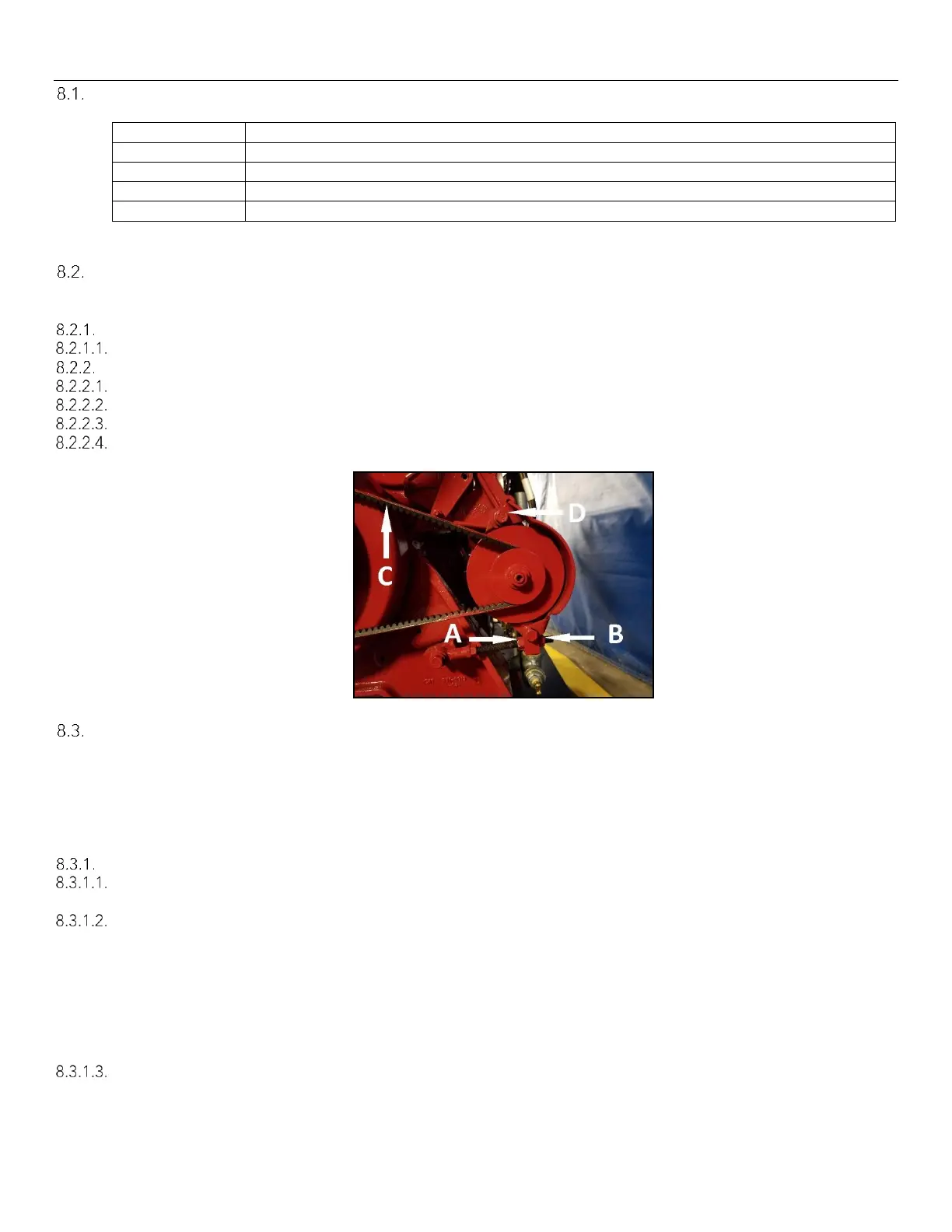

Checking Drive Belt Tension and Adjustment

All drive belts must be adequately tightened to secure that both the engine water pump and battery charging

alternator (when fitted) are operating efficiently. Refer to Figure #8-1.

To adjust Belt Tension:

Check belt tension: Give at arrow C must be approx. 0.5” (12.7mm)..

To increase tension of the alternator driving belts:

Loosen nut at D.

Loosen nut B on adjustment rod.

Tighten nut A to push the alternator to the right to tighten the belt. Do NOT overtighten the belt.

Tighten mounting nut B to lock adjustment in place.

Figure 8-1

Overspeed

In the event of an engine overspeed, the ECM signals the main pump controller and also affects an engine

shutdown. Should an overspeed condition occur, investigate the cause and make necessary corrections before

placing engine back in service. The overspeed reset switch must be manually lifted for 30 seconds to reset.

After reset, the Powerview Gauge will display “no data” for engine parameters. Cycle the ECM selector switch

to Alternate ECM and back to Primary ECM before attempting to restart the engine.

Overspeed Verification

Hold the OVERSPEED VERIFICATION switch in the “up” position. This will provide the main pump controller

with an overspeed signal and engine shutdown at 30 RPM’s below the rated RPM.

Start the engine via the main pump controller; the speed switch will generate an overspeed signal and

shutdown protecting both the engine and pump.

EXAMPLE

Rated Speed: 1760 RPM

Overspeed Shutdown: 2112 RPM (120% of 1760 RPM)

Verification Shutdown: 1730

After verification of overspeed, lift the OVERSPEED RESET switch and reset the main pump controller to re-

instate normal operation of the engine and speed switch. Cycle the ECM selector from the ECM in use to the

other ECM and back again after lifting the OVERSPEED RESET

Loading...

Loading...