46

Close the manual ball valves on the automatic and bypass side of the cooling loop to prevent raw water

from flowing through the cooling system.

NSR Tube Bundle Removal

Remove the Crossover End Cap

Locate the Crossover End Cap (reference figure 9-1 item 1)

Remove the Crossover End Cap bolts (qty 5).

Remove the Crossover End Cap (reference figure 9-1 item 1)

Remove the rubber O-Ring and dispose.

Remove the IO (In/Out) End Cap

Locate the IO End Cap (reference figure 9-1 item 2)

Remove the IO End Cap bolts (qty 5).

Remove the IO End Cap (reference figure 9-1 item 2)

Remove the rubber O-Ring and dispose.

Remove the tube bundle

Identify the 12 o-clock mark on the tube bundle header plate from the IO side of the assembly and

make note of its position.

Remove the tube bundle by sliding it out of the IO side of the assembly. (reference figure 9-1 item 3)

NSR Tube Bundle Cleaning

Clean the Tube Bundle

Submerge the tube in de-scaler for 30 minutes to 1 hour.

Inspect the inside of the tubes. If needed, use a cleaning rod and brush to clean the tubes.

Rinse tube bundle thoroughly with fresh water and let dry.

NSR Tube Bundle Installation

Install the Tube Bundle

Install the tube bundle from the IO side of the assembly. (reference figure 9-1 item 2)

Ensure the 12 o-clock marking is in the correct position, facing the IO side and not the crossover side.

Ensure the tube bundle is centered in the housing. Measure from the mating surface of the shell

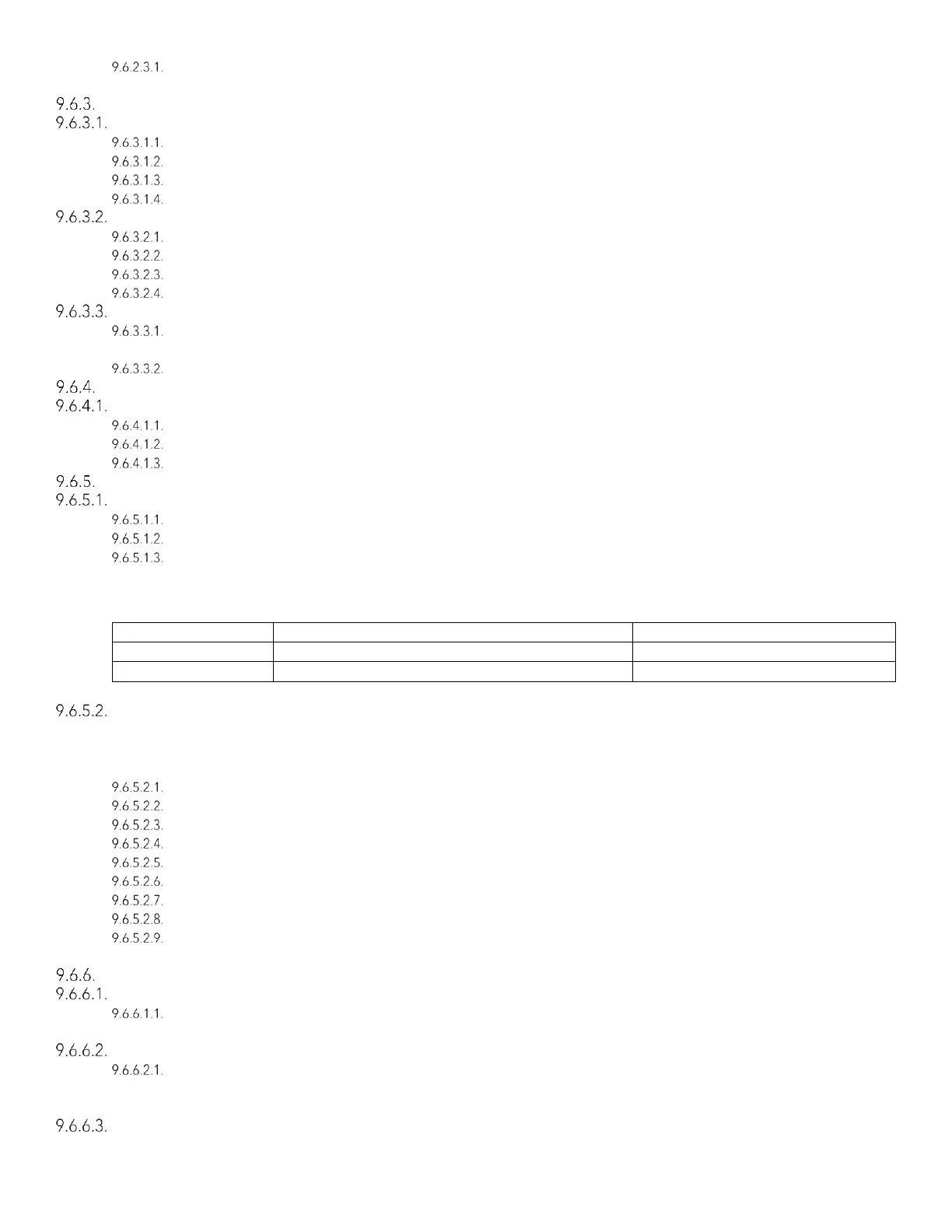

assembly to the header plate. This measurement should be equal to the value in table 1. Note: The

header plate can float, ensure the header plate is flush with the cup.) Reference figure #9-1.

Table 1

Install the End Caps

IMPORTANT: Install the End Caps as described below, ensuring that the bundle does not shift from the

centered position. If the bundle moves at any point during end cap installation, remove the end cap

and repeat step 5.1.2 and 5.1.3 before attempting again.

Lubricate all surfaces of a new O-Ring (part number 0C12C979).

Install O-ring into Crossover side of the assembly. Ensure the O-ring is fully seated inside the groove.

Place the Crossover End Cap onto the shell assembly and finger tighten the 5 bolts in the assembly.

Lubricate all surfaces of a new O-Ring (part number 0C12C979).

Install O-ring into IO (In/Out) side of the assembly. Ensure the O-ring is fully seated inside the groove.

Place the IO End Cap onto the shell assembly and finger tighten the 5 bolts in the assembly

Hand tighten the 5 bolts on the Crossover End Cap assembly.

Hand tighten the 5 bolts on the IO End Cap assembly.

Properly torque the Crossover End Cap and IO End Cap Bolts to 31 FT-LBS in the sequence shown

below in figure #9-2.

Return to Normal Operation

Refill the engine coolant

Refill the engine coolant using Clarke Fire part number 0C054129 or Cool-Gard II part number

TY26575

Turn on the raw water supply

Return the manual ball valves on the automatic and bypass side of the cooling loop to the normal

position. IMPORTANT: Ensure the manual ball valves are in the normal position. Restricting raw water

flow to the cooling system will cause the engine to overheat.

Return the engine to normal operation

Loading...

Loading...