24

SETTINGS AND ADJUSTMENTS

Occasionally, it may be necessary to readjust various components in order to maintain

optimum performance. The adjustments that may be performed are as follows:

A. Compound Slide Adjustments

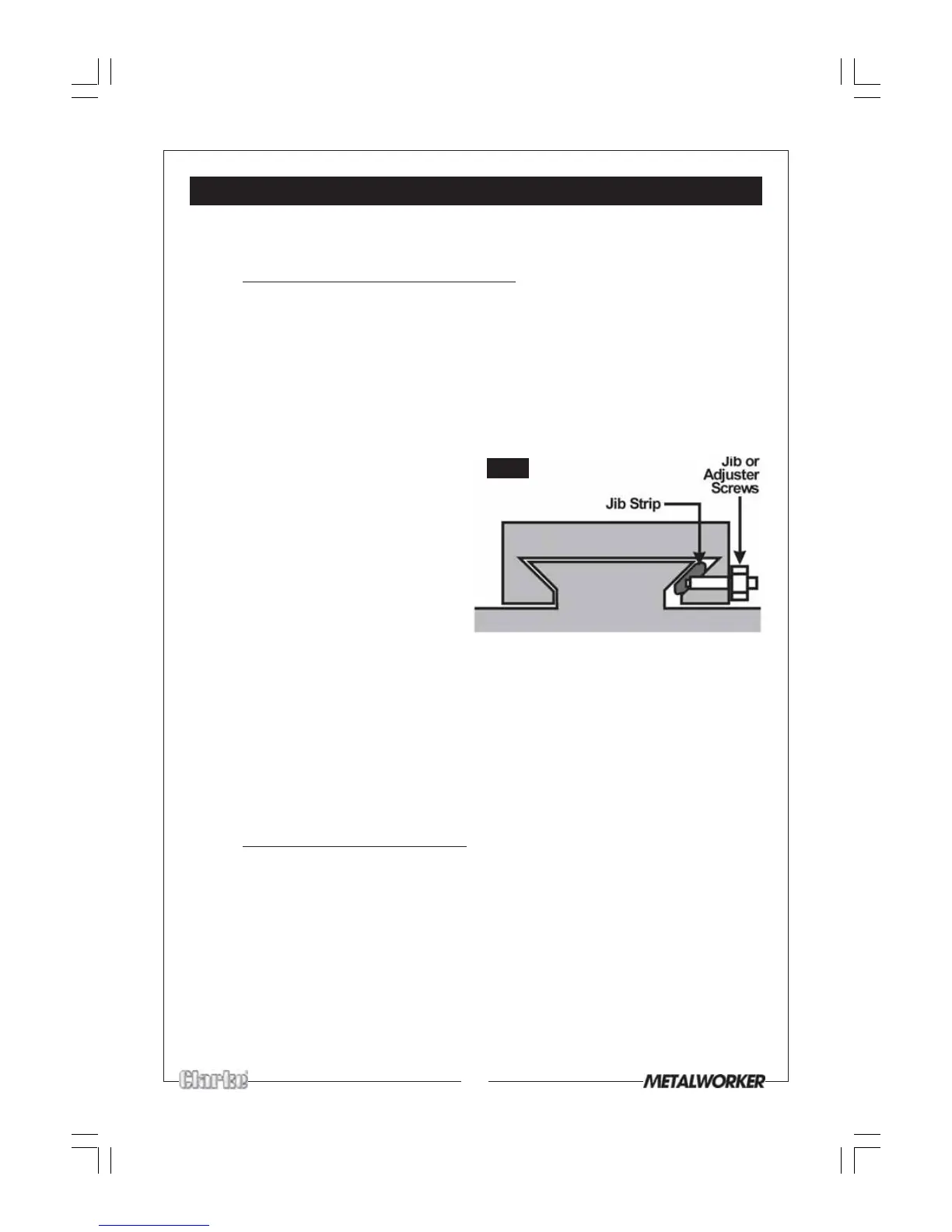

The cross-slide is mounted on a dovetail slide, as shown in Fig. 23. Between the

sloping surfaces on one side of the dovetail, a ‘jib strip’ is inserted, which may be

tightened against the dovetail under the influence of adjuster, or ’jib’ screws,

mounted along its’ length.

The jib screws are to be found on the left hand side of the slide. In time, wear will

occur on the mating surfaces resulting in a ‘sloppiness’ of action.

To adjust the jib strip, to account for wear and ensure the slide moves evenly and

smoothly, proceed as follows:

1. Slacken off all lock nuts and screw

in the jib screws evenly, i.e. use the

same torque for each screw. The

slide should be held firmly. Test by

trying to turn the handle, but do

not force it.

2. Screw out each jib screw by one

quarter of a turn ONLY, and nip up

the lock nuts

3. Test again, by turning the handle. The

movement should be even and smooth along its complete length.

4. If the movement is too slack, screw all adjusters ‘in’ by one eighth of a turn, and

retry. Similarly, if the movement is too stiff, screw ‘out’ the adjusters by one

eighth of a turn until the correct adjustment is attained.

5 Tighten all lock nuts taking care to ensure you do not move the jib screws whilst

doing so.

6. When completed, retract the slide fully and apply oil to all mating surfaces and

the feed screw thread, then wind the slide back to its normal position.

B. Cross-slide Feed Handle

The cross-slide feed should run smoothly, and the scale must rotate with the handle.

If any stiffness occurs, it is probably the result of swarf lodging between the mating

surfaces. Undo the securing hex. socket head screw securing the handle. Remove

the handle and pull off the collar with the scale. Take care to retain the small spring

plate which sits in a groove beneath the collar.

Tip - Turn the shaft anticlockwise so that a small gap occurs between the mating

surfaces, sufficient for small levers to be inserted. It will be quite stiff initially so care

must be taken not to cause damage to mating surfaces when prising it off.

Clean the assembly and reassemble in reverse order ensuring the spring plate is

correctly positioned.

Fig.23

Loading...

Loading...