10

Mounting the Mill Head

Remove the protective greased paper from the headstock mounting, and ensure

the surface is clean and undamaged.

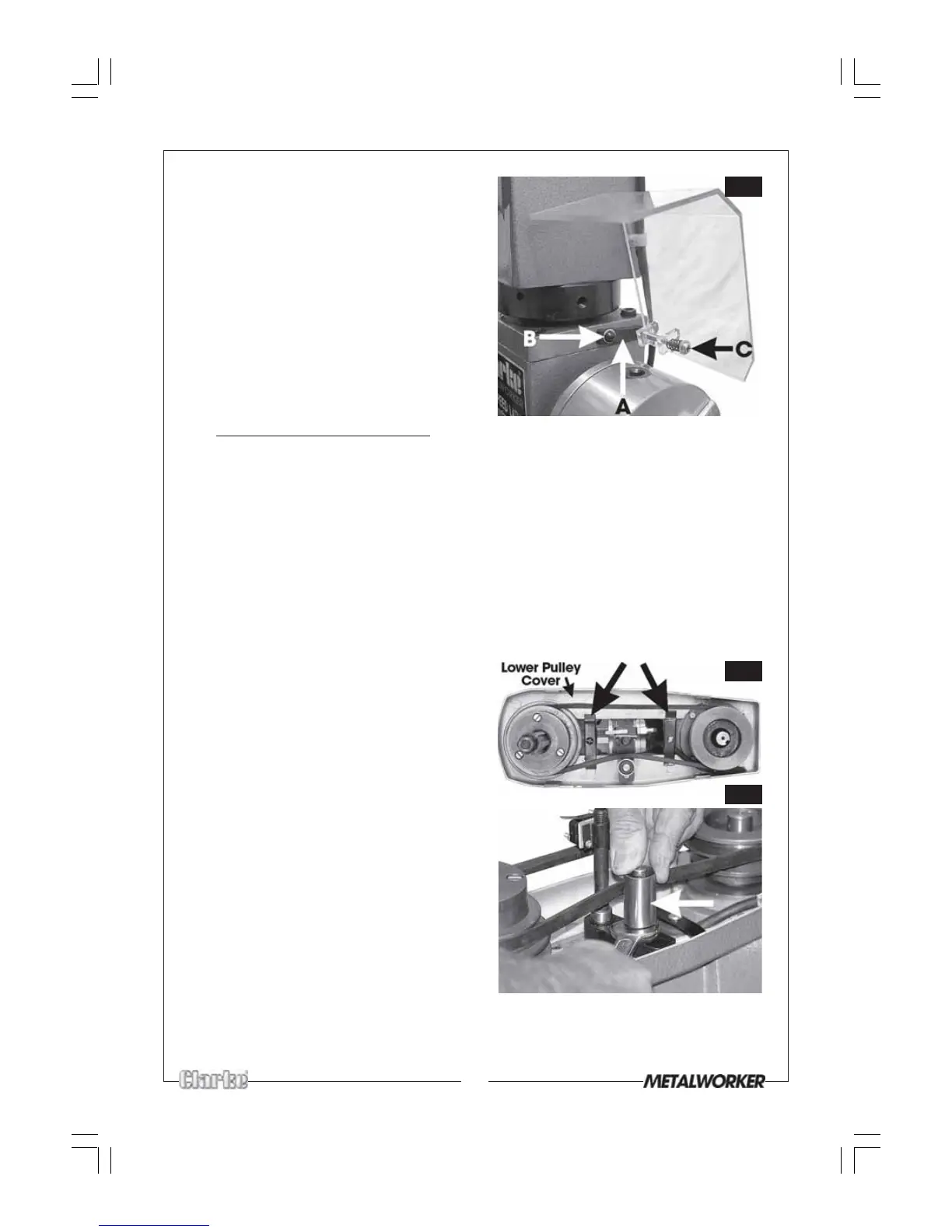

• Carefully raise the Mill Head, noting that the plastic lower pulley cover is not fully

secured at this stage and is vulnerable. Very carefully lower the head on to its

mounting on the headstock. Secure with the four Hex socket head screws provided.

• If the cable to the microswitch has been disconnected, it should now be

replaced and the cable secured in the clamps on the side of the mill head.

• You will note that cable is secured with a clamp plate, adjacent to the pulley.

similar clamp is provided in the box of loose parts, and this should be screwed

in place adjacent to the Driven Pulley so that the lower pulley cover is properly

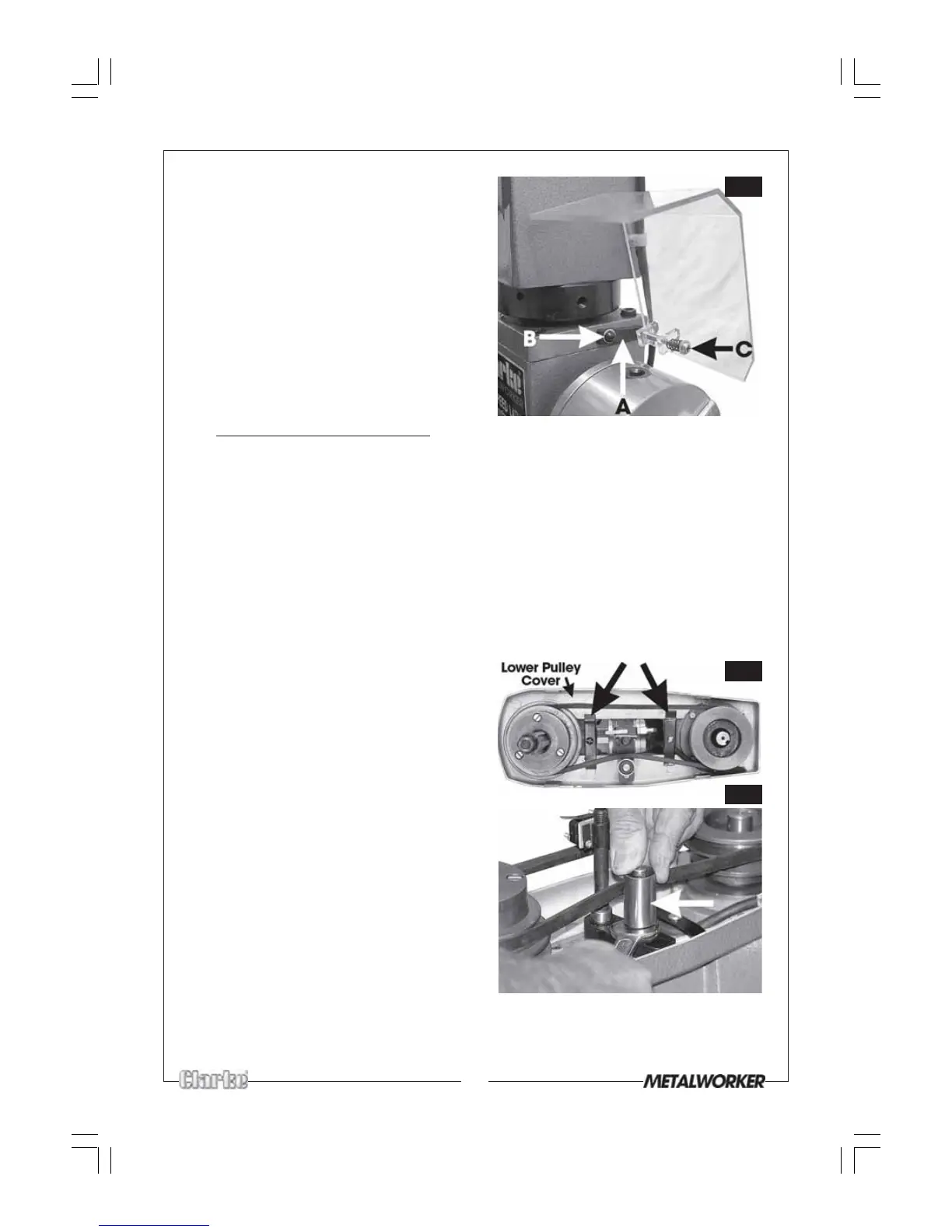

• Fit the Chuck Guard according to Fig.5.

CL500M: Remove the transit screw in

the base of the Mill Head from the

position arrowed at ‘B’, (if fitted).

Secure the Stop Bar ‘A’ with the screw

and flat washer ‘B’ found in the guard kit.

The screw attached to the Guard -

’C’ is threaded through the remaining

hole in the stop bar, and screwed into

the headstock....note the rounded

end of the stop bar is at the guard

pivot end...or to the right side.

secured. Do not overtighten as this

will distort the cover.

Both clamps are arrowed in Fig. 6

• Slip the drive belt over the pulleys in the

manner shown in Fig 6.

• Slacken the nut securing the belt

tension roller as shown in Fig.7)

sufficient for the roller to be moved

inwards, in the direction of the arrow,

thereby applying tension to the belt.

Retighten the nut when the belt

may be deflected by approx. 1/2

inch, when applying reasonable

pressure, in the middle of its run

between the pulleys.

• Place the pulley cover in position and

secure with the large knob provided.

NOTE: It is important to ensure that the

microswitch is activated when the cover

Fig.7

Fig.5

is in place. If you do not hear an audible click when the cover is lowered into

place, you must remove the cover and raise the microswitch, on the rod, until a

click is heard when the cover is replaced. Ensure the microswitch is properly secured.

Fig.6

Loading...

Loading...