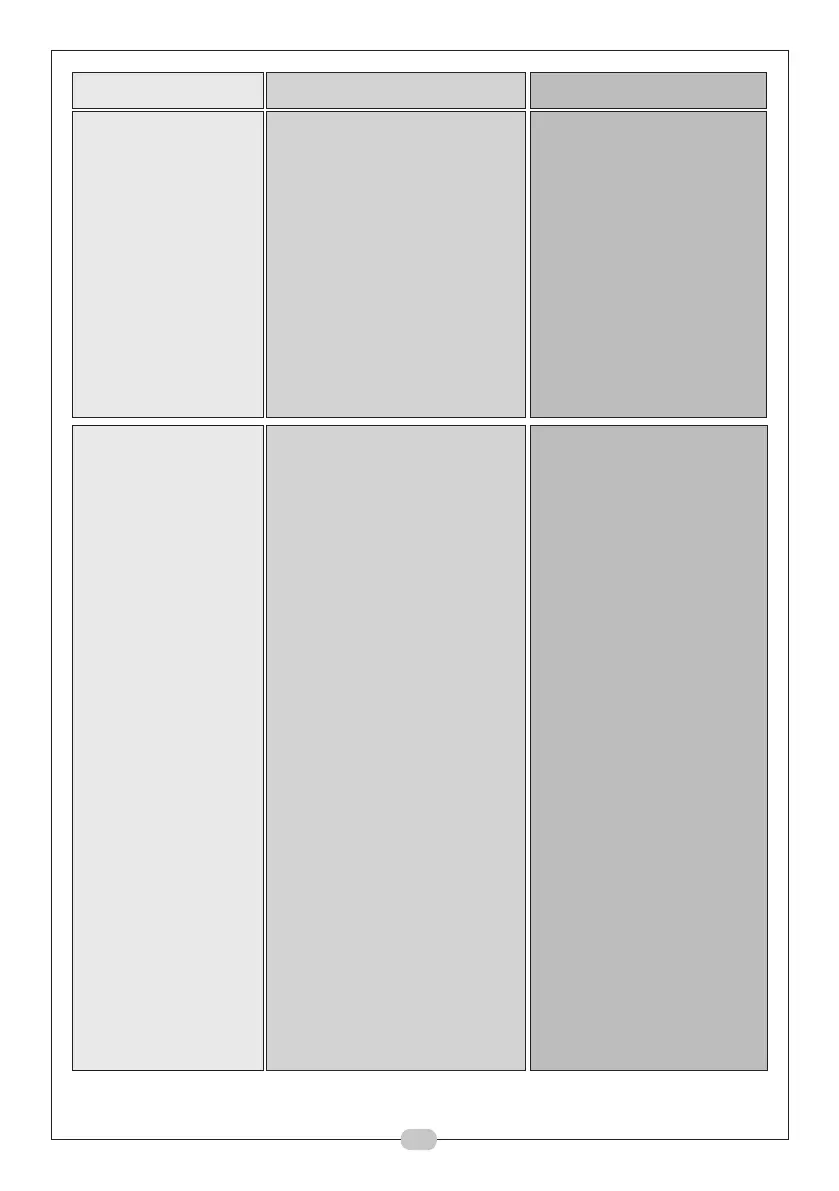

SYMPTOM PROBABLE CAUSES REMEDY

Unusual noise from Bolts loose. Tighten Bolts.

compressor. V-Belt flywheel or cooling Find place of contact and

coil touching belt guard remedy fault.

Flywheel loose. Tighten flywheel.

Unit installed on an Move unit to a more solid

unsuitable base. base.

Bearings, piston rings or Contact Clarke Service

cylinder worn. Department

Valve broken. Contact Clarke Service

Department

Bearings of electric motor Contact Clarke Service

worn. Department.

Compressor becomes Insufficient ventilation See that sufficient air is

too hot. supplied to flywheel or

fan of compressor and

that hot air is properly

vented.

Oil level too low (check Fill with oil - see Page 6.

2 or 3 times after stopping).

Wrong direction of Cooling air from flywheel

rotation. fan must blow against

compressor.

Fault in valves (machine Contact Clarke Service

not stopping). Department

Blown head gasket (machine Contact Clarke Service

not stopping). Department

Dirt on cooling fins or Clean cooling fins and

suction filter. suction filter.

Unit working at too high Contact Clarke Service

a pressure Department.

Non-return valve partly Clean or thaw out non-

blocked. return valve.

Compressor being Use a larger compressor

overworked and

running continuously.

11

Loading...

Loading...