Profire V Burner Chapter 2

750-177 2-13

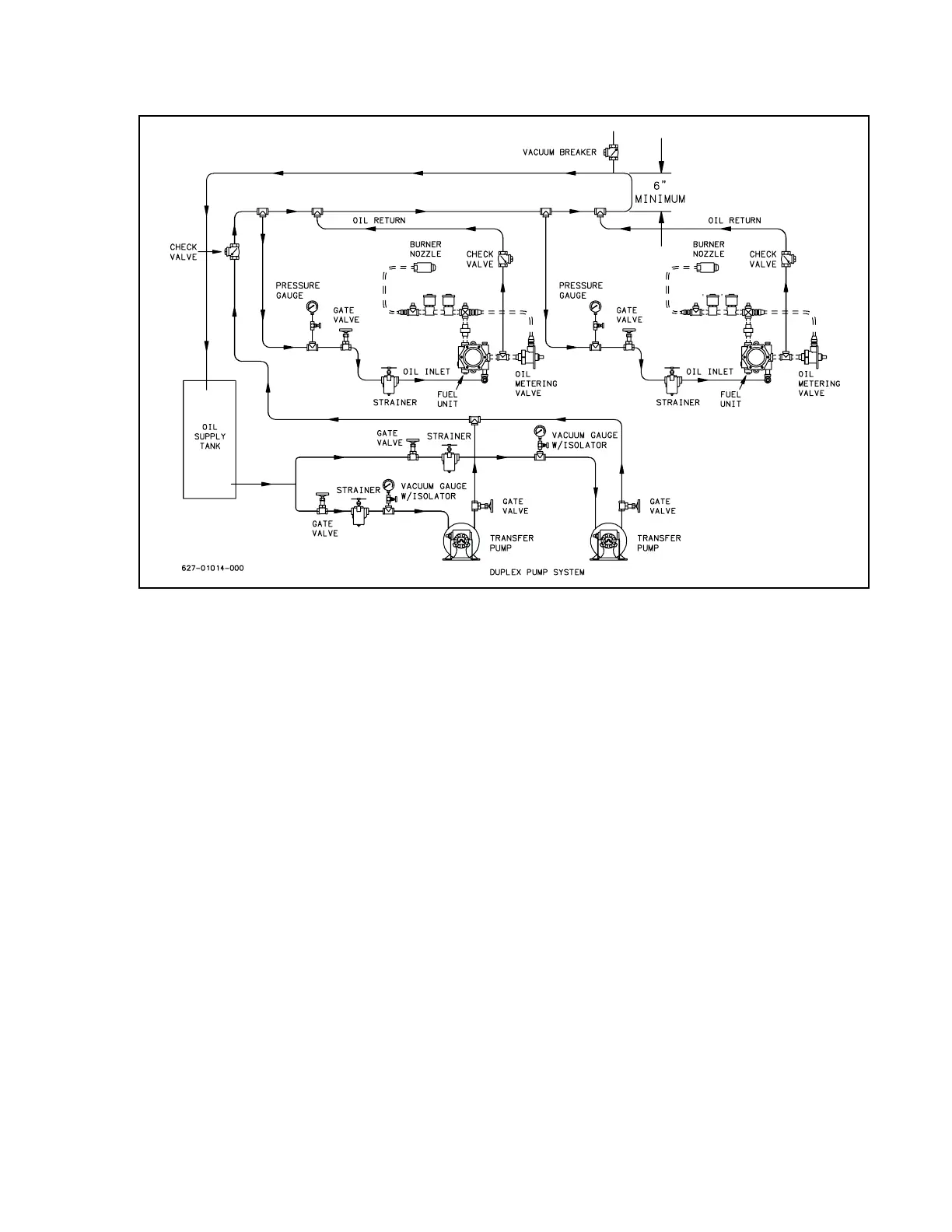

Figure 2-12: Typical Flooded Loop System

GAS PIPING

Refer to Figures 2-5 through 2-6 for typical gas piping arrangements.

Normally, the control train is ordered to

suit a particular code or insurance regulation, such as UL/cUL, FM, or GAP. Gas service and house piping must

supply the quantity of gas demanded by the unit at the pressure required at the burner gas train inlet.

All piping must be in strict accordance with applicable codes, ordinances, and re

gulations of the supplying

utility. In the absence of other codes, piping should be in accordance with National Fuel Gas Code, NFPA No.

54, ANSI No. Z223-1.

Gas train components upstream of the butterfly valve

are shipped loose. These components should be

mounted by the installer as close to the butterfly valve as practical. If a pre-piped and wired gas train is

ordered, the components upstream of the first safety shutoff valve are shipped loose. These components

should also be mounted by the installer.

Arrange gas piping at the burner so that

the burner is accessible for servicing without disassembly.The pilot

gas train is supplied with the burner, and is factory installed. The gas pilot supply line must be connected

upstream of the main gas regulator. If a reducing bushing is required between the house piping and the burner

piping, it should be close to the burner shutoff valve.

The gas piping must be internally clean and free of foreign

material. Before using in service, a leak test must

be performed.

Loading...

Loading...