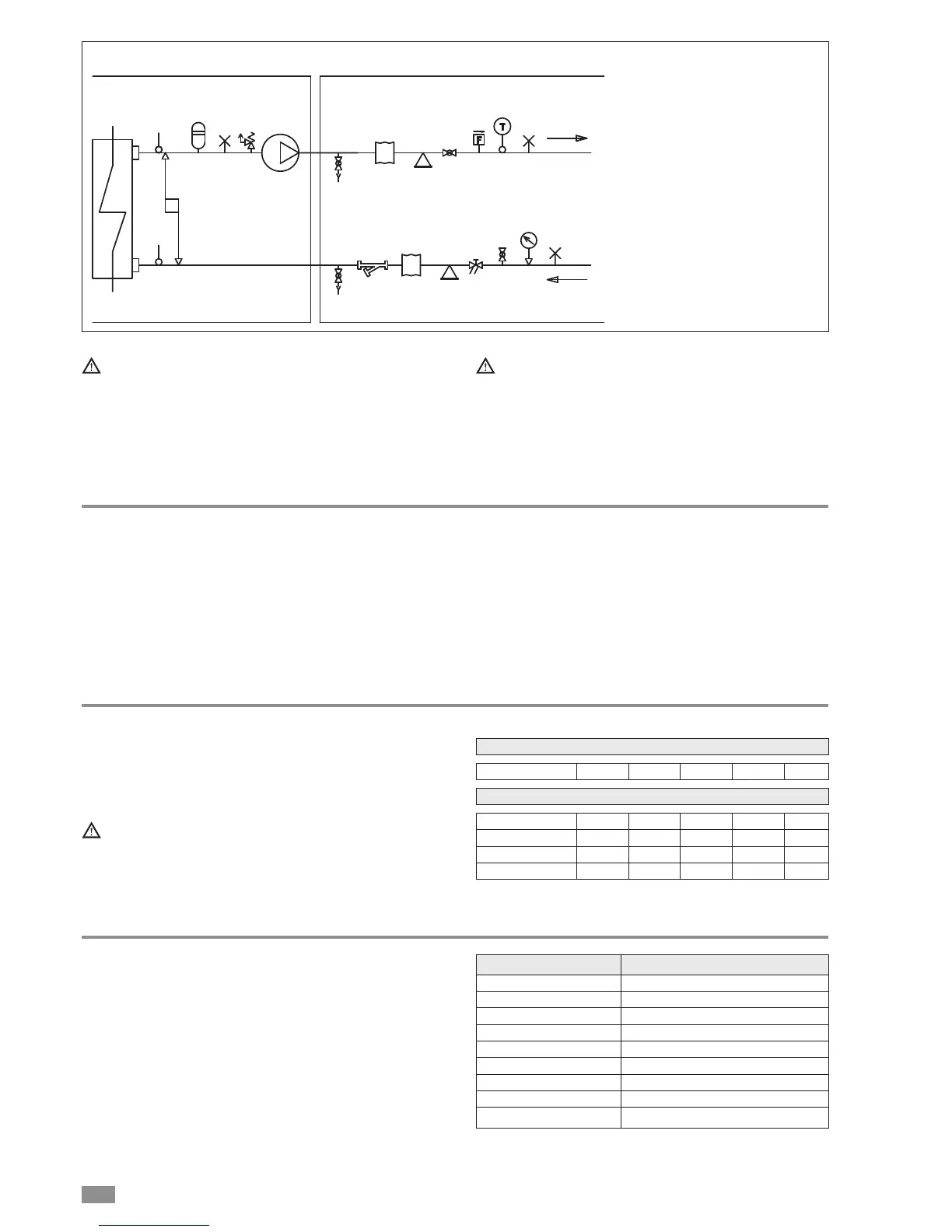

System water circuit connection diagram, BRN2 version WITH HYDRONIC KIT

1 PRESSURE GAUGE

2 VIBRATION-ISOLATING JOINT

3 SHUT-OFF VALVE

4 CALIBRATING VALVE

5 FLOW SWITCH

6 THERMOMETER

7 CIRCULATOR PUMP

8 SAFETY VALVE

9 EXPANSION VESSEL

10 MESH FILTER

11 FILL/TOP-UP

12 TEMPERATURE PROBE

13 DIFFERENTIAL PRESSURE

SWITCH

14 DRAIN/CHEMICAL WASHING

VALVE

15 SYSTEM VENT

Must be provided with a filling/top-up system connected

to the return line and a drain cock in the lowest part of

the installation.

Installations containing antifreeze or covered by spe-

cific legislation must be fitted with water circuit discon-

nectors.

The manufacturer is not liable for obstruction, breakage

or noise resulting from the failure to install filters or

vibration dampers.

Particular types of water used for filling or topping up

must be treated with appropriate treatment systems.

For reference values, see the table.

Risk of freezing

The unit must be prevented from freezing at outside air tem-

peratures around 0°C.

The following are recommended:

• use suitable percentages of antifreeze (see “Ethylene gly-

col solutions”)

• protect the piping with heating sheaths,

• empty the system, making sure no water remains at the

lowest points in the circuit or there are closed valves

where water may stagnate.

It is recommended to use non-toxic food grade antifreeze,

compliant with the standards in force in the countries where

the unit is used, if domestic hot water production is also fea-

tured.

The antifreeze used must be corrosion inhibited and com-

patible with the water circuit components.

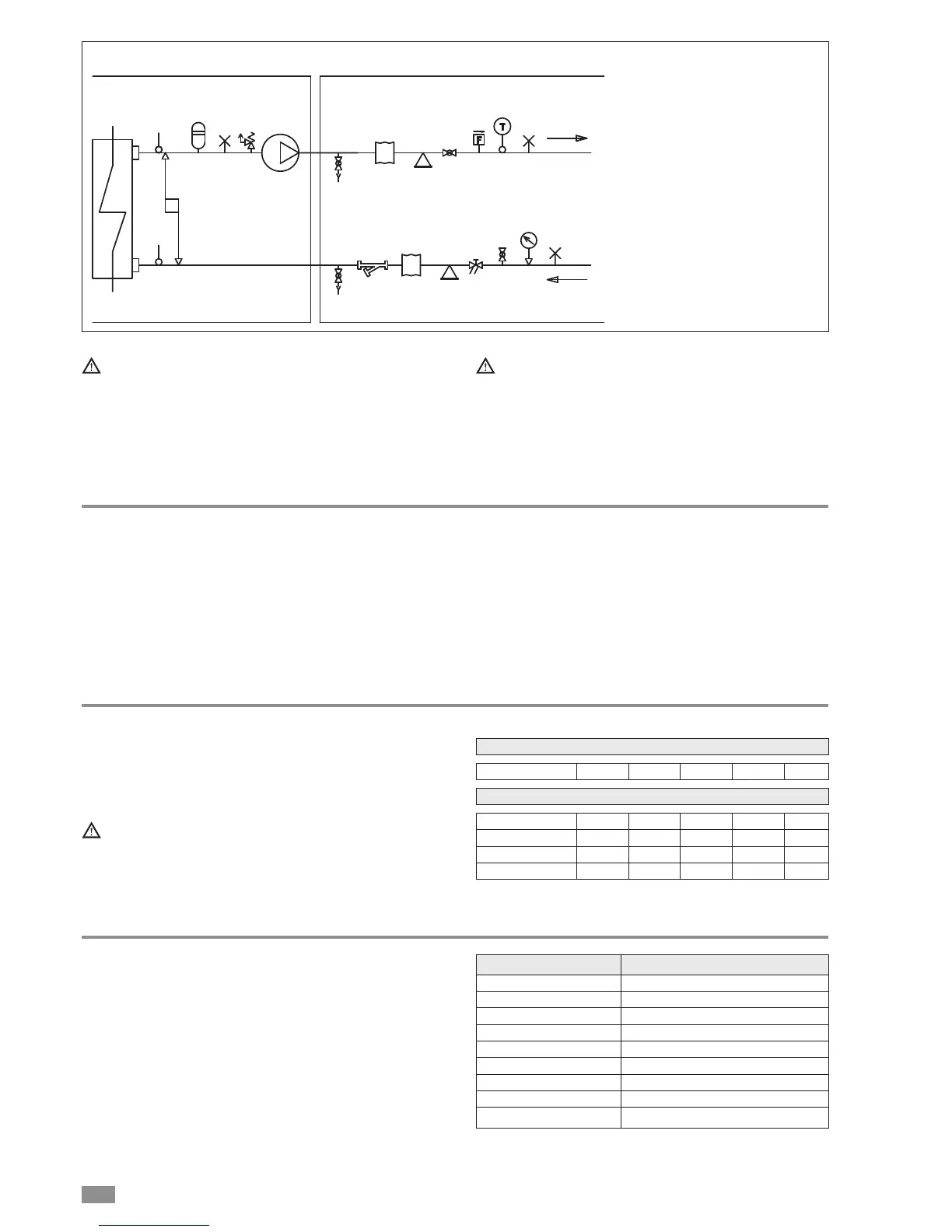

Ethylene glycol solutions

Water and ethylene glycol solutions used as a heat carrier in

the place of water reduce the performance of the unit.

Multiply the performance figures by the values given in the

following table.

The heat pumps must be fitted with a filling/top-up sys-

tem connected to the return line and a drain valve in the

lowest part of the system.

Systems containing antifreeze or covered by specific

legislation must be fitted with low-loss headers.

cPf

cQ

cdp

0

1

1

1

12%

0,985

1,02

1,07

20%

0,98

1,04

1,11

28%

0,974

1,075

1,18

35%

0,97

1,11

1,22

40%

0,965

1,14

1,24

0 -5 -10 -15 -20 -25

Freezing point (°C)

Percentage of ethylene glycol by weight

cPf: cooling capacity correction factor

cQ: flow rate correction factor

cdp: pressure drop correction factor

Water quality

The water used in the system and domestic hot water cir-

cuits must comply with the following characteristics:

PH 6-8

Electrical conductivity less than 200 mV/cm (25°C)

Chlorine ions less than 50 ppm

Sulphuric acid ions less than 50 ppm

Total iron less than 0.3 ppm

Alkalinity M less than 50 ppm

Total hardness less than 50 ppm

Sulphur ions none

Ammonia ions none

Silicon ions less than 30 ppm

Loading...

Loading...