Incremental encoder

The electrical connection of an incremental encoder is described in the chapter

Connection of the goods scanners. The programming is described in the chapter

Testmode. Now the mechanical attachment of the conveyor to the encoder will be

described.

If the speed measuring is done by an incremental encoder, the measured speed can be

fine adjusted by ±10 % with the SPEED potentiometer. The DATA HOLD switch only

stores the potentiometer setting. The dispensing speed will follow the product speed.

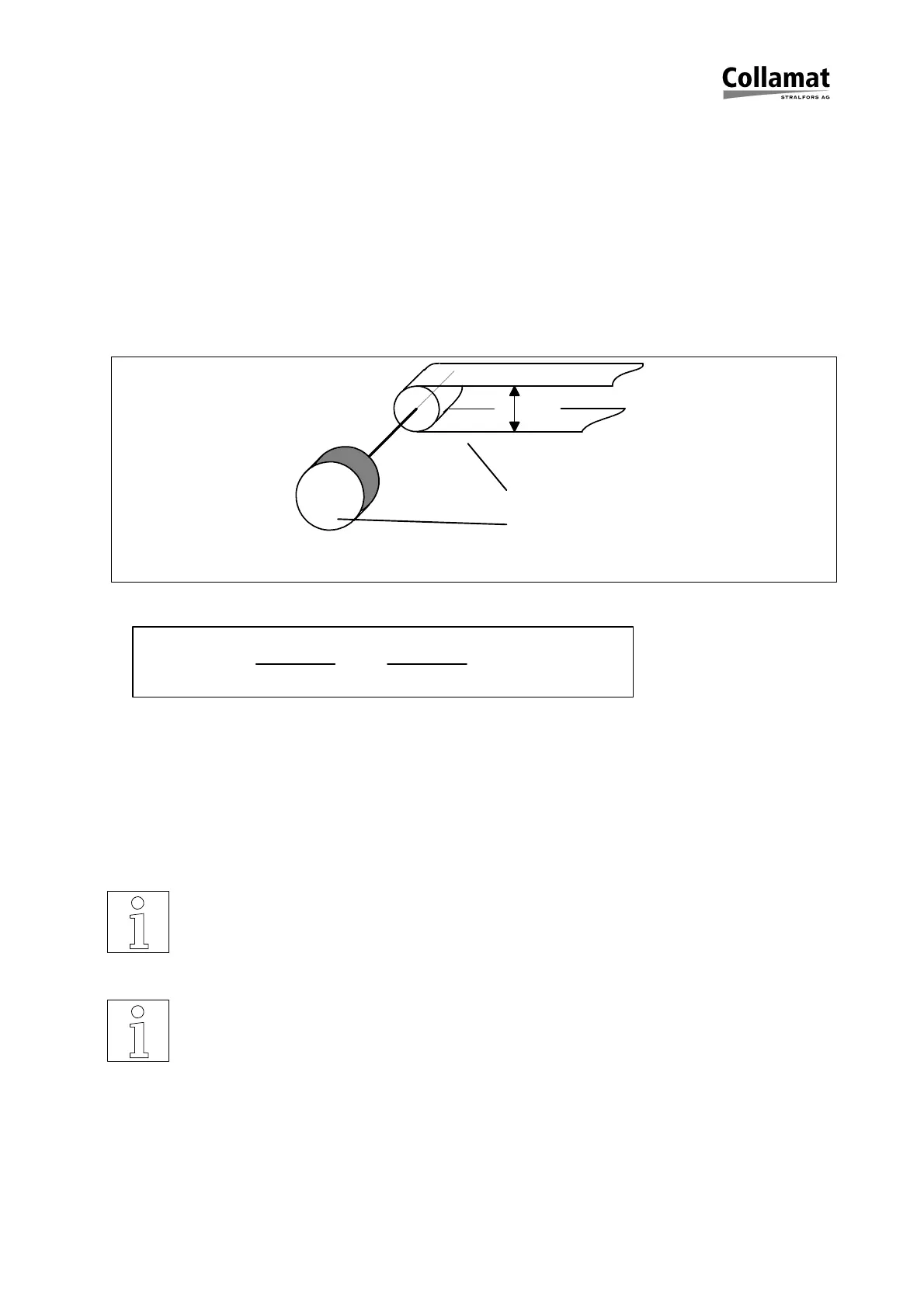

Figure 18 shows an example how to calculate the step width:

1: 200 / turn

2: d = 100 mm

Figure 18: Incremental encoder

Example:

Step =

The step width must be in between 1.00 mm and 9.99 mm. For small distances betwe-

en the products, the stepping rate must be as small as possible. 2 mm are a good

practice value.

The minimum dispensing speed is 3 m/min, the maximum speed is 30 m/min. If no

incremental encoder is attached to the dispenser or if the conveyor is stopped, the

dispensing speed will be 3 m/min.

Remark:

The minimum distance between two products is equal to 6 times the

step width.

Remark:

The dispensing speed is captured at the moment of the detection of the

product. At this moment the dispensing speed will not change until the

label is completely dispensed !

d

1

2

=

=

314mm

200

d * Pi

Pulse

1.57mm

5999.527-01A 25.11.98 WM Seite 26 / 32

Loading...

Loading...