NOTICE: Automotive batteries should never be used for "deep cycle" application, as their useful life will be

very short.

Install surge arrestors on incoming AC power lines. Surge arrestors will help protect electrical/electronic

components in the charger and vehicle from all but direct or “close proximity” lightning strikes.

Damaged or corroded battery terminals should be replaced or cleaned as necessary. Failure to do so may

cause overheating during operation.

Do not attempt to recharge batteries with a charger not designed for your vehicle.

Only trained technicians should service the Delta Q charger. Contact your Columbia Dealer for assistance.

4.2 BATTERY INSPECTION & MAINTENANCE

Check the electrolyte level on new batteries before they are put into service, and, at a minimum, once a week

thereafter. Water use increases as batteries age. (See Section 4.12 if vehicle is equipped with a Single Point Battery

Watering System.)

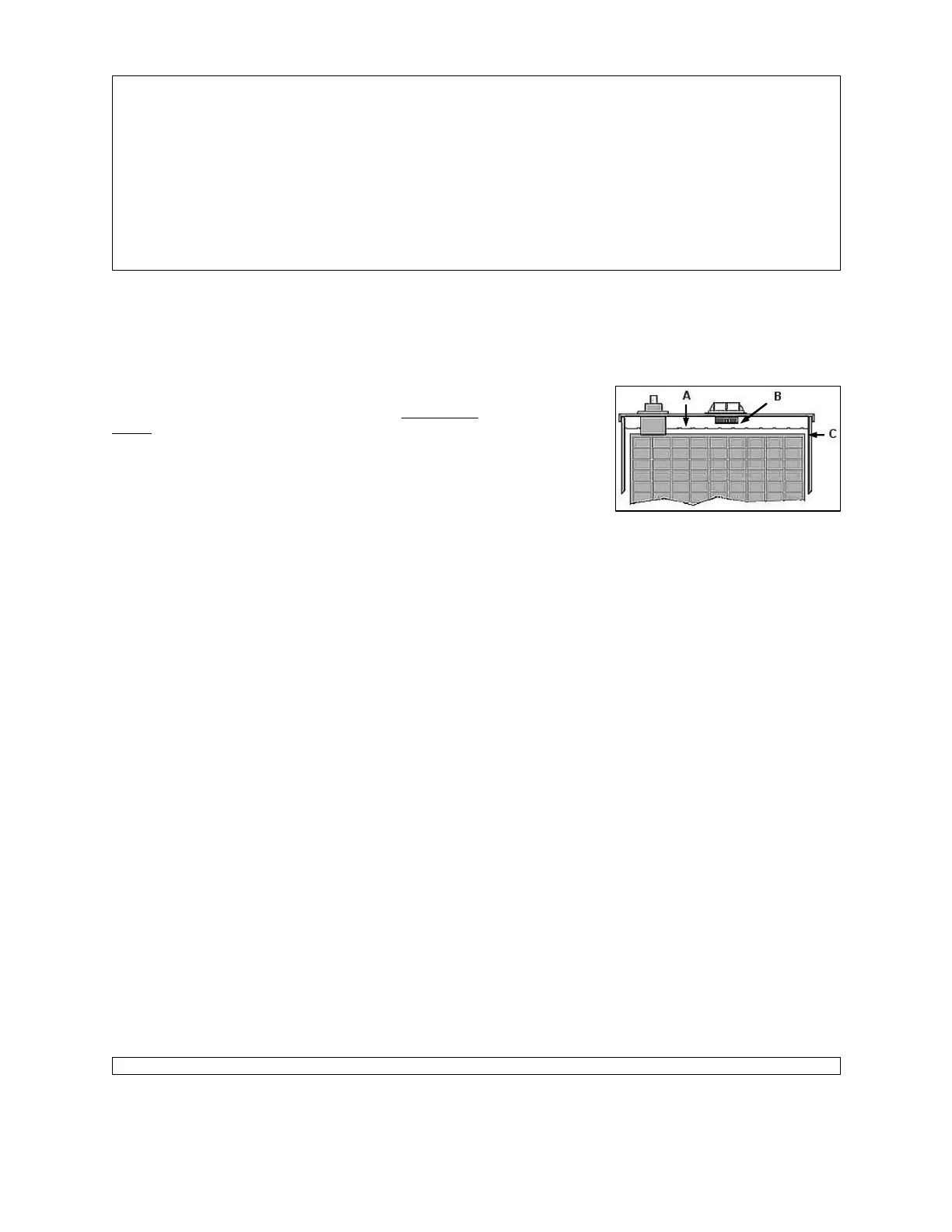

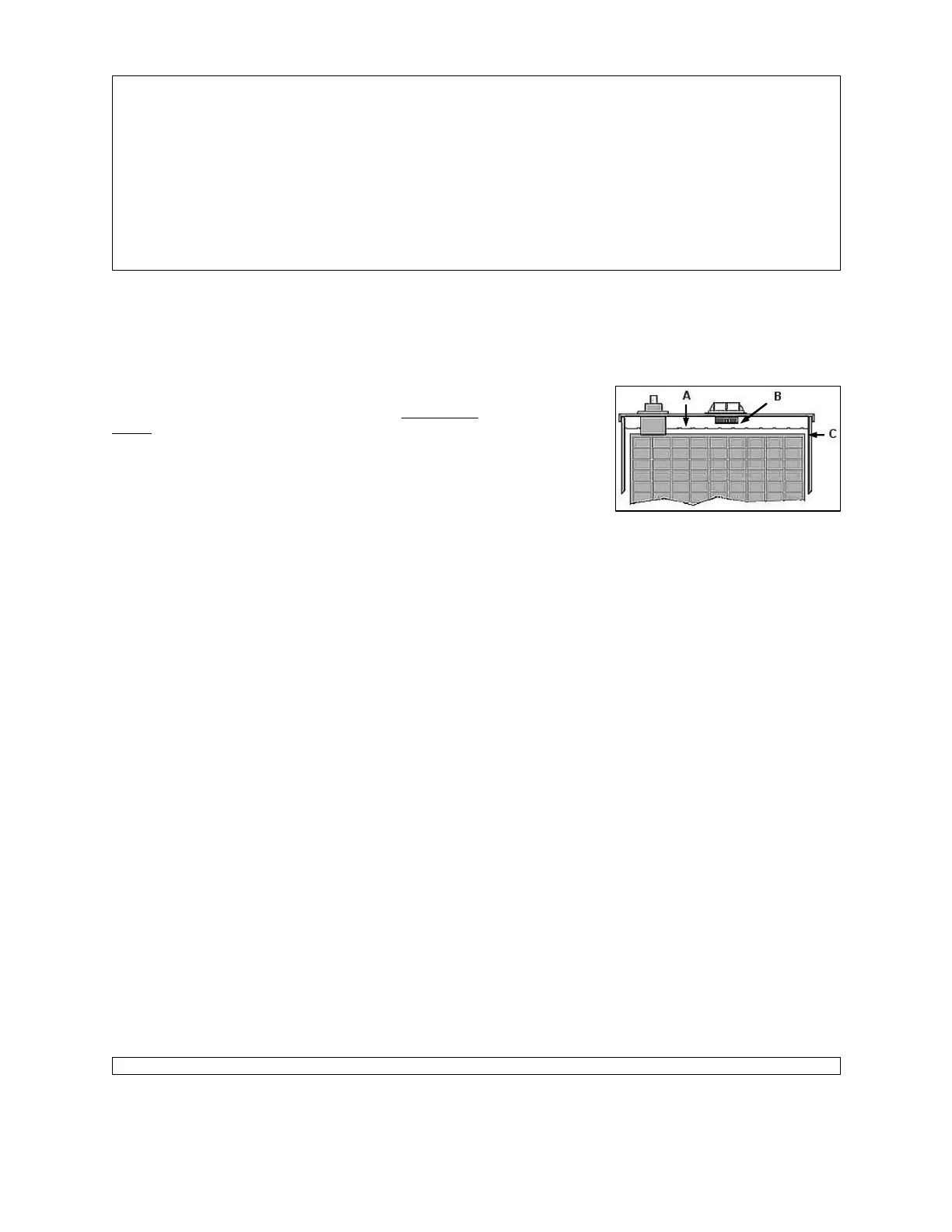

See Figure 4.2.1. Never allow the electrolyte level (A) to fall below the top of

the plates (C). If the plates are exposed, add only enough

to cover the plates

before

charging. After batteries are fully charged, fill cells to just below the

bottom of the cell vents (B), approximately 1/8” to 1/4”. Electrolyte level should

not touch the bottom of the cell vents.

Do not ov

erfill batteries. Electrolyte expands and can overflow during charging.

Water added to replace the spillage dilutes the electrolyte and reduces its

specific gravity.

Figure 4.2.1

Use on

ly distilled water. Vehicle batteries may use up to 16 quarts of water during their useful life and non-distilled

water may contain harmful minerals which will have a cumulative adverse effect on battery performance and life.

Be sure battery hold downs are properly tightened. A loose hold down may allow the battery to become damaged

from vibration or jarring. A hold down that is too tight may buckle or crack the battery case.

Weekly inspect battery posts, clamps and cables for breakage, loose connections and corrosion. Replace any that

are damaged. Check to see that battery cap vent holes are clear. Plugged vent holes will not permit gas to escape

from the cell and could result in battery damage. Batteries and connections must be clean and dry. See Section 4.3.

Weekly an equalization charge is to be applied to the battery pack. This process balances the electrical charge in the

battery pack and will extend battery life. The following procedure is used to complete this.

Charge the battery pack allowing the Delta-Q Charger to go to green 100% charge.

Once the green LED lights unplug the power cord.

Wait approximately 30 seconds. Reconnect the power cord and allow the Delta-Q to complete a second charge

cycle.

If the vehicle is not to be used, leave power cord connected. The Delta-Q can test and recharge as needed.

4.3 BATTERY CLEANING

Acid-soaked debris on the battery terminal connections will cause current leakage, reduces battery efficiency, and

battery life.

Check that all vent caps are tightly in place. Hose wash battery terminal connections periodically with clean low-

pressure water to keep them free of acid spillage, dirt, and other debris. Do not hose wash electronic controllers,

switches, solenoids and other electrical control devices. Cover as necessary to prevent splashing.

Clean battery terminal connections with baking soda (sodium bicarbonate) and water solution. Mix 5 teaspoons

baking soda per quart of water. Use a stiff bristle brush, rinse with clean water and dry with a clean cloth. Do not

allow solution to enter cap vent holes.

NOTICE: F

ollow local ordinances and codes for proper disposal of battery cleaning waste.

BC 2012

4-2

Loading...

Loading...