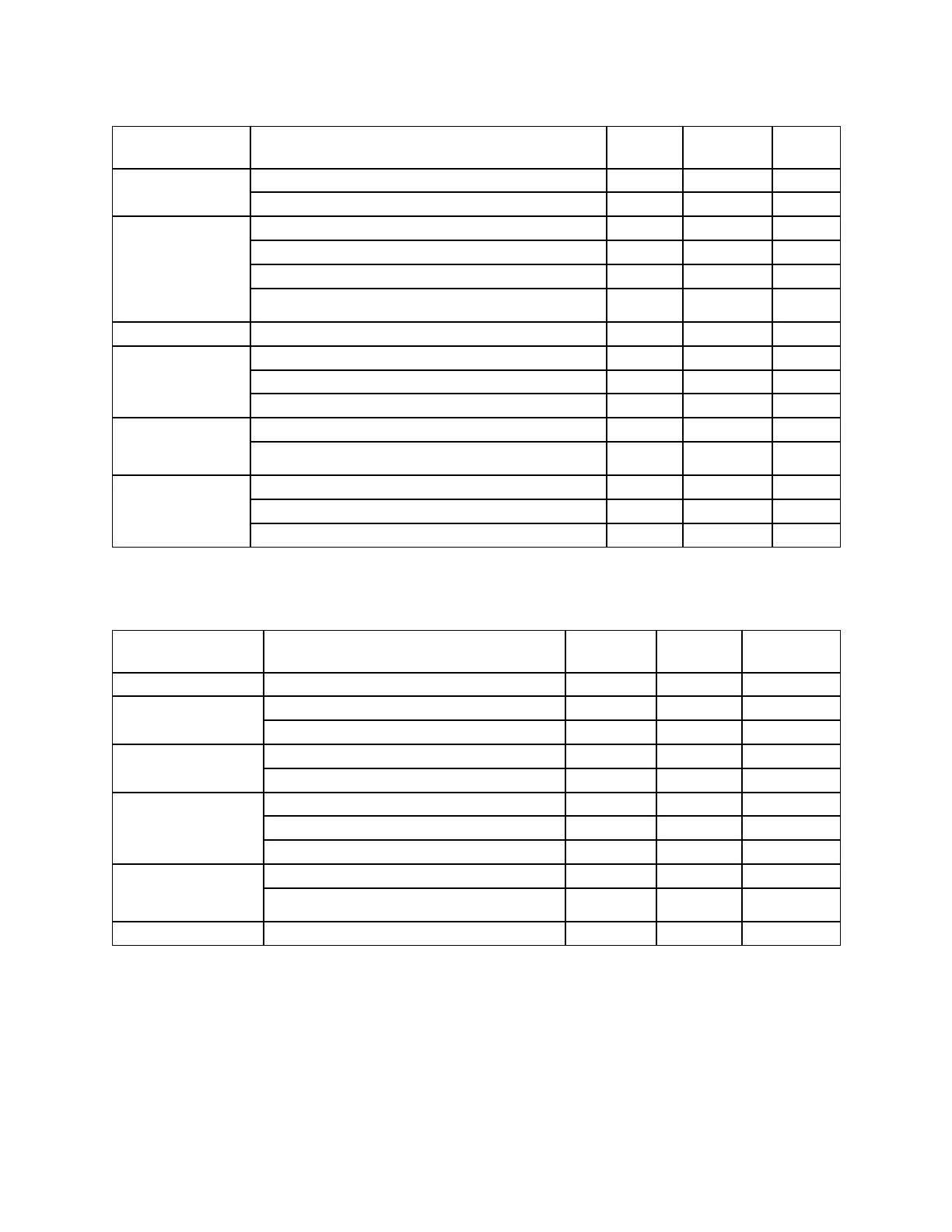

5.2 MAINTENANCE SCHEDULE

5.2.1 OWNER/OPERATOR

Item Operation Weekly Monthly

Semi-

annual

Lug nuts tight.

*

Tires

Check tire pressure, wear, damage, dented rims.

*

Check electrolyte level.

*

Apply equalization charge to the battery pack.

*

Clean battery terminals and wash cases.

*

Electrical

Check the general condition of the electrical system

(connections, frayed/broken cables, etc.).

*

Brakes

Pedal & park brake operation.

*

Inspect for loose hardware (bolts & nuts, etc.).

*

Clean body and seats, Wash as needed.

*

Body and Frame

Wash engine/motor compartment and undercarriage.

*

Visual check for differential leak.

*

Lube

Oil movement points (body hinges, brake mechanisms

and linkage, leaf spring bushings etc.)

*

Add water per Section 4.12.

*

Check condition of tubing, couplers. Secure & leak free.

*

Single Point

Watering System

Clean filter screen.

*

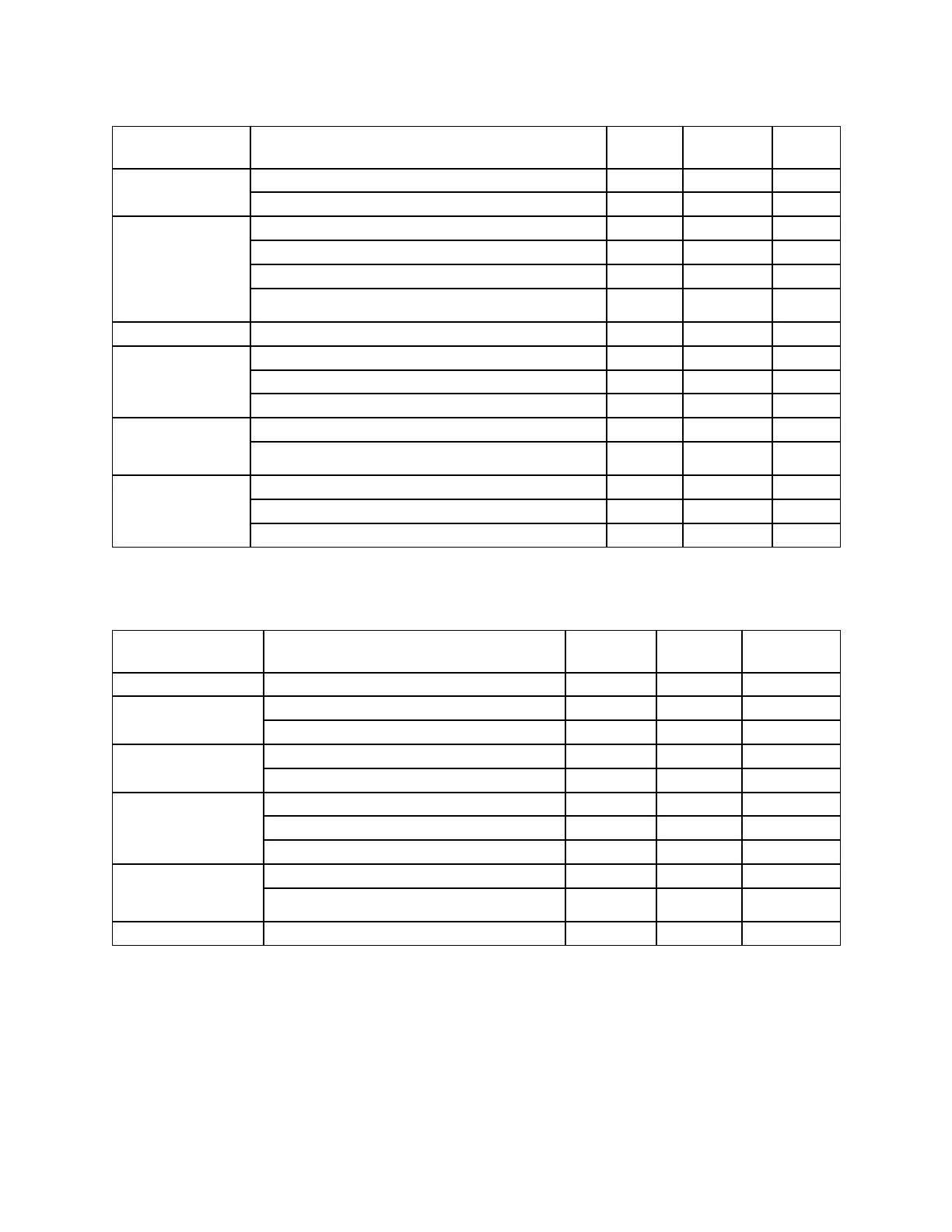

5.2.2 QUALIFIED TECHNICIAN

It is recommended that the following be performed by a trained qualified technician or your Columbia Dealer

Item Operation Quarterly

Semi-

Annual

Annual

Tires

Front wheel alignment and camber.

*

Test batteries.

*

Electrical

Inspect motor condition and operation.

*

Check brake pads, clean & adjust brakes.

*

Brakes

Check brake fluid.

*

Check differential fluid level.

*

Grease fittings.

*

Lube

Grease steering gear.

*

Check wheel axle nuts for tightness & torque.

*

Wheel

When equipped,- wheel bearings, repack,

replace if needed

*

Accelerator

Check micro switch adjustment (If equipped)

*

5.3 BRAKE SYSTEM

5.3.1 BRAKE FLUID MAINTENANCE

Check the brake fluid in the master cylinder periodically (under normal conditions, every 3 months). The master

cylinder is located under the front deckboard and seat assembly. Use DOT 3 Motor Vehicle Brake Fluid. Maintain

fluid level within 1/4" of master cylinder filler opening.

5-2

BC 2012

Loading...

Loading...